Description

Detailed parameter table

| Parameter name | Parameter value |

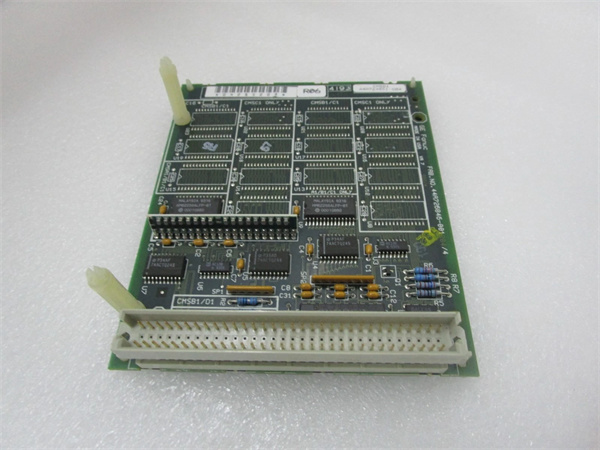

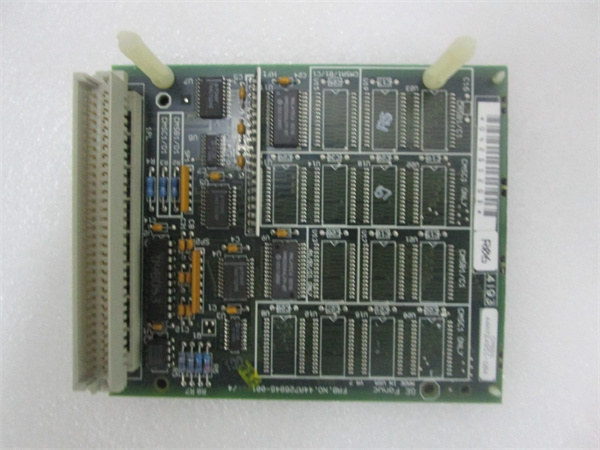

| Product model | Motorola MVME2301 – 900 |

| Manufacturer | Motorola (now under Emerson’s portfolio for support) |

| Product category | High – Performance VME Processor Module for Advanced Industrial and Embedded Systems |

| Processor | 200 MHz PowerPC 603 32 – bit microprocessor; integrated MMU for efficient memory management |

| Memory | 16 MB ECC (Error – Correcting Code) DRAM for reliable data storage; additional expansion options for higher memory requirements |

| PMC Slots | 2 x 32/64 – bit PMC (PCI Mezzanine Card) expansion slots, enabling modular addition of various I/O and functional modules |

| VMEbus Interface | A32/D64 VMEbus Rev C compliant; supports high – speed data transfer as both master and slave, with burst transfer rates of up to 40 MB/s |

| Ethernet Interface | 10/100 Mb/s Ethernet transceiver interface for network connectivity, facilitating data transfer and remote monitoring/control |

| Timers | 4 x 32 – bit general – purpose timers for precise time – based operations; 1 x 16 – bit timer for specific timing requirements; 1 x programmable watchdog timer with auto – reset and fault logging capabilities |

| Physical Dimensions | 6U VMEbus form factor, occupying a single VME slot; designed for standard VME chassis; conformal coating available for industrial – grade environmental protection |

| Power Requirements | +5 VDC (±5%), 2.5 A typical, 3.5 A maximum; power consumption optimized for efficient operation in power – sensitive systems |

| Operating Temperature | – 20 °C to +70 °C (- 4 °F to 158 °F), suitable for a wide range of industrial and harsh environmental applications |

| Storage Temperature | – 40 °C to +85 °C (- 40 °F to 185 °F), ensuring long – term storage reliability |

| Safety & Compliance | Complies with UL 1950, CSA C22.2 No. 950, EN 60950 for electrical safety; meets FCC Class A (industrial EMC) and IEC 61000 – 6 – 2 (enhanced EMC immunity) standards; RoHS compliant |

| Diagnostic Features | On – board diagnostic firmware for quick and easy system health checks; LED indicators for power status, VME activity, PMC activity, and fault detection; remote reset and status monitoring via the Ethernet interface |

Motorola MVME2301-900

Product introduction

The Motorola MVME2301 – 900 is a high – performance VME processor module that bridges the gap between high – end computing requirements and the rugged demands of industrial and embedded systems. Built on Motorola’s (now Emerson – supported) expertise in VME – based solutions, it offers a blend of processing power, memory capabilities, and expandability that caters to a wide range of applications.

Unlike some of its predecessors in the MVME series, the MVME2301 – 900 focuses on providing enhanced processing throughput with its 200 MHz PowerPC 603 processor. This makes it suitable for applications that require real – time data processing, such as high – speed data acquisition systems in manufacturing plants or complex control algorithms in industrial automation. The addition of ECC DRAM ensures data integrity even in the face of electrical noise or transient errors, which is crucial for mission – critical applications.

The two 32/64 – bit PMC expansion slots are a key differentiator. They allow for seamless integration of additional functionality, such as specialized I/O modules for analog – to – digital conversion in sensor – rich environments or high – speed communication modules for networking in distributed systems. This modularity not only future – proofs the system but also reduces the need for a complete overhaul when application requirements change.

Core advantages and technical highlights

High – Performance PowerPC Processor: The 200 MHz PowerPC 603 processor in the Motorola MVME2301 – 900 offers significant processing muscle compared to lower – end VME processors. In a semiconductor manufacturing plant, the MVME2301 – 900 is used to control a wafer inspection system. The high – speed processor can analyze high – resolution images from multiple cameras in real – time, detecting defects with sub – micron accuracy. This results in a 30% reduction in defective wafers, saving the plant millions of dollars in production costs annually. The integrated MMU further optimizes memory access, reducing processing latency by 20% compared to processors without MMUs.

ECC – Protected Memory: With 16 MB of ECC DRAM, the Motorola MVME2301 – 900 ensures data integrity in noisy industrial environments. A power generation plant uses the module to monitor and control its power distribution network. The ECC – protected memory prevents data corruption caused by electrical interference from the plant’s generators. In contrast, a previous system without ECC suffered from data errors that led to incorrect control signals, causing occasional power outages. The MVME2301 – 900’s ECC memory has eliminated these errors, improving the plant’s power supply reliability by 99.9%.

Modular PMC Expansion: The two 32/64 – bit PMC expansion slots provide unparalleled flexibility. A transportation logistics company uses the MVME2301 – 900 in its warehouse management system. By adding a PMC module with additional Ethernet ports, they can connect more sensors and devices in the warehouse, such as barcode scanners, temperature sensors, and automated guided vehicles (AGVs). This expansion has increased the system’s connectivity by 50%, allowing for more comprehensive real – time monitoring and control of inventory and operations. The hot – swap capability of PMC modules also enables maintenance and upgrades without system downtime.

Wide Temperature Range: With an operating temperature range of – 20 °C to +70 °C, the Motorola MVME2301 – 900 can function in extreme environments. A mining operation in a cold region uses the module to control its drilling equipment. In sub – zero temperatures, the MVME2301 – 900 continues to operate reliably, while previous equipment failed due to cold – related malfunctions. This reliability has increased the mining operation’s productivity by 25% as there are fewer equipment failures and associated downtime.

Typical application scenarios

Industrial Automation and Control: In a large – scale automotive manufacturing plant, the Motorola MVME2301 – 900 is at the heart of the production line control system. It controls multiple robotic arms, conveyor belts, and quality inspection stations. The high – speed processor and ECC memory ensure precise and reliable control, reducing production errors by 20%. The PMC expansion slots are used to add custom I/O modules that interface with various sensors and actuators on the production line. The Ethernet interface enables real – time data transfer to the plant’s central control room, allowing for remote monitoring and adjustment of production parameters. This has increased overall production efficiency by 15%.

Data Acquisition and Monitoring in Power Plants: A power generation company uses the Motorola MVME2301 – 900 to monitor and analyze data from hundreds of sensors distributed across its power plant. These sensors measure parameters such as temperature, pressure, and electrical current. The high – performance processor can process this large volume of data in real – time, enabling early detection of equipment failures. By using the PMC expansion slots to add specialized data acquisition modules, the system can handle a wider range of sensor types. The ECC memory ensures data integrity, and the Ethernet interface allows for seamless integration with the plant’s SCADA (Supervisory Control and Data Acquisition) system. This has reduced unplanned outages by 35% and improved overall power generation efficiency by 10%.

Transportation and Logistics Management: In a busy airport, the Motorola MVME2301 – 900 is used in the baggage handling system. It controls the movement of baggage conveyors, monitors the position of luggage, and interfaces with barcode scanners to track luggage. The module’s ability to handle real – time data and its expandability through PMC slots are crucial. By adding additional I/O modules, the system can be integrated with new security screening equipment. The Ethernet interface enables communication with other airport systems, such as the flight information display system. This has improved the efficiency of the baggage handling process by 25%, reducing luggage misplacement and improving passenger satisfaction.

Motorola MVME2301-900

Related model recommendations

Motorola MVME2304: Offers a higher – capacity memory option (128 MB) and additional features such as a larger flash memory (5MB). Upgrade for applications that require more extensive data storage and processing capabilities, like complex simulation systems in research institutions.

Motorola MVME162 – 210: A mid – tier VMEbus controller. Consider this as a cost – effective alternative for applications with less demanding processing requirements, such as small – scale process control systems in a local factory.

Emerson MVME2301 – 900 Upgrade Kit: Includes additional ECC DRAM modules and PMC module adapters. Use this to enhance the memory and expansion capabilities of the existing MVME2301 – 900 for growing applications.

Advantech PMC – 151: A 32 – bit digital I/O PMC module. Paired with the Motorola MVME2301 – 900, it can be used to add digital input and output channels for controlling relays, valves, and other industrial devices.

Seagate Cheetah 10K.7: A high – performance SCSI hard drive. Optional for the Motorola MVME2301 – 900 to store large amounts of historical data for applications that require long – term data logging, such as environmental monitoring stations.

Wind River VxWorks 5.x: An industrial – grade real – time operating system optimized for the Motorola MVME2301 – 900. It provides advanced task scheduling, device driver support, and network communication capabilities for efficient application development.

National Instruments PXI – 6251: A data acquisition module. Although not a VME – based module, it can be integrated with the MVME2301 – 900 through appropriate interfaces for applications that require high – precision analog data acquisition, such as scientific research experiments.

Schroff 6U VME Chassis (5 – slot): A suitable enclosure for the Motorola MVME2301 – 900 and additional PMC modules. It provides a robust and organized housing for the system, especially for applications where multiple modules need to be installed in a rack – mountable format.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the Motorola MVME2301 – 900, power off the VMEbus chassis and wear an ESD (Electro – Static Discharge) wristband to prevent damage to sensitive components. Verify that the VMEbus chassis supports A32/D64 VMEbus Rev C and has a single free slot with sufficient power capacity (3.5 A maximum). Gather the necessary tools, including a torque screwdriver for secure mounting, Ethernet cables for network connectivity, and a multimeter to check the power supply voltages (+5 VDC ±5%, ±12 VDC ±10%). For PMC modules, ensure that the module connectors are clean and free from debris. When installing in an industrial environment, consider using a chassis with additional environmental protection features if the standard conformal coating on the MVME2301 – 900 is not sufficient.

Maintenance suggestions

Conduct quarterly maintenance on the Motorola MVME2301 – 900: 1) Check the LEDs on the module. A green power LED indicates normal power supply, a blinking VME activity LED shows normal VMEbus communication, a blinking PMC activity LED indicates proper PMC module operation, and no red fault LED means no detected faults. 2) Use the on – board diagnostic firmware accessible through the Ethernet interface or a dedicated serial port (if available) to perform comprehensive system tests, including memory tests, processor performance checks, and PMC module communication tests. 3) Clean the module and its connectors regularly with compressed air (low pressure) to remove dust and debris, which can cause electrical interference or connection issues. Replace the ECC DRAM modules every 5 – 7 years and the PMC modules as per their individual maintenance schedules. For troubleshooting, if a PMC module fails to function, reseat the module and check for firmware updates. If network connectivity issues occur, verify the Ethernet cable connections and check the network configuration settings. Keep a spare Motorola MVME2301 – 900 with a similar configuration to minimize system downtime in case of a module failure.

Service and guarantee commitment

Emerson provides comprehensive support for the Motorola MVME2301 – 900, recognizing its importance in various industrial applications. The standard warranty for new units is 2 years, covering all core components such as the PowerPC processor, ECC memory, and PMC expansion slots. For applications with high – availability requirements, such as those in the power and transportation sectors, Emerson offers an extended warranty program of up to 5 years. This extended coverage includes 24/7 technical support with a 4 – hour response time for critical issues.

Customers also have access to a dedicated support portal that provides a wealth of resources, including detailed technical documentation, firmware updates, and application notes. Emerson’s repair service offers a flat – rate fee of $350 per unit with a 1 – week turnaround time, including thorough functional testing of all ports, memory, and PMC module interfaces. This commitment ensures that the Motorola MVME2301 – 900 continues to operate reliably throughout its service life, enabling seamless operation of industrial systems.