Description

Detailed Parameter Table

| Parameter name | Parameter value |

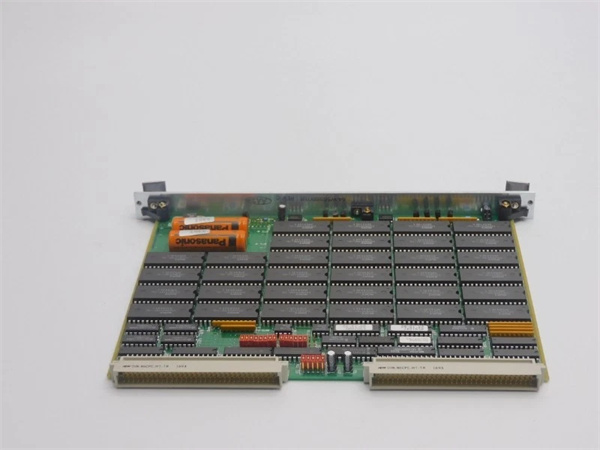

| Product model | Motorola MVME215-3 |

| Manufacturer | Motorola (now part of Emerson Industrial Automation) |

| Product category | Legacy Industrial VMEbus Analog Output (AO) Module (dedicated actuator control) |

| Analog Output (AO) | 8 channels; Output ranges: ±5V DC, ±10V DC, 0–5V DC, 0–10V DC (per-channel configurable); Resolution: 12-bit |

| Output Performance | Full-scale settling time: <10 µs; Linearity error: ±0.05% full scale; Output drift: <5 ppm/°C |

| Isolation | Channel-to-channel isolation: 250V AC (rms); Module-to-VMEbus isolation: 500V AC (rms); Short-circuit protection: 500 mA (per channel, auto-recover) |

| Communication Interface | VMEbus A16/D16 slave interface (IEEE 1014-1987 compliant); Polled + interrupt-driven data update; 4 configurable fault interrupt vectors |

| Environmental Requirements | Operating Temp: -20°C–70°C (-4°F–158°F); Storage Temp: -40°C–85°C (-40°F–185°F); Humidity: 5%–95% (non-condensing); Vibration: 10–2000 Hz, 2.0 g (rms); Shock: 70 g (peak, 1 ms) |

| Physical Size | 3U VMEbus form factor: 100 mm × 160.0 mm (3.94 in × 6.30 in); Weight: 340 g (0.75 lbs) |

| Power Consumption | Typical: 7 W (25°C, 8 channels active); Maximum: 10 W (all channels at full load) |

| Calibration | On-board 0.001% precision voltage reference; Software-calibratable (no mechanical potentiometers); Auto-drift compensation |

| Diagnostic Features | LED indicators (power, channel active, short-circuit fault, module health); Over-temperature protection; Output voltage monitoring |

| Compatible Host SBCs | Motorola MVME-147SB-1, Motorola MVME162-043, Motorola MVME-2700-761-I/O

Product Introduction |

Motorola MVME215-3

The Motorola MVME215-3 is a legacy industrial VMEbus analog output module designed for high-precision, high-reliability actuator control—specializing in converting digital control signals from host SBCs into continuous analog voltages to drive valves, motors, and other precision actuators. As a premium model in the Motorola MVME 215 series, Motorola MVME215-3 differs from input-focused modules like the Motorola MVME-224-2 (analog input) or combined I/O modules like the Motorola MVME-226-2 (mixed AI/AO) by dedicating its design to analog output performance, delivering 8 channels of ultra-stable, low-drift signals.

In automation systems, Motorola MVME215-3 acts as a “precision control signal generator”: it receives digital setpoints from host SBCs (such as Motorola MVME-2700-761-I/O) and converts them into analog voltages to regulate actuators—for example, adjusting the opening of a proportional control valve or the speed of a servo motor. This dedicated focus eliminates the performance compromises of combined modules, making Motorola MVME215-3 ideal for closed-loop control applications—such as chemical reactor temperature control, pharmaceutical batch mixing, and aerospace test rig actuation—where sub-millivolt signal accuracy directly impacts process quality and safety.

Core Advantages and Technical Highlights

Ultra-Precision + Low Drift: Motorola MVME215-3 delivers 12-bit resolution with ±0.05% linearity error and <5 ppm/°C drift—outperforming the Motorola MVME-226-2’s AO drift of <10 ppm/°C. This stability ensures consistent actuator control over wide temperature ranges, critical for long-duration processes. For example, in a pharmaceutical fermentation tank requiring 37°C ±0.1°C temperature control, Motorola MVME215-3 outputs a 0–10V signal to a heating element controller with <0.01V drift over 24 hours—maintaining temperature accuracy without frequent recalibration. The on-board 0.001% reference (10x more precise than basic modules) further guarantees signal integrity.

Fast Settling + Short-Circuit Protection: With full-scale settling time <10 µs, Motorola MVME215-3 responds rapidly to control changes—essential for dynamic systems like robotic arm position control. In an automotive assembly line, the module can update the voltage to a servo motor driver in <10 µs, ensuring the arm adjusts its position within 5 ms to align with a workpiece. Each channel also includes 500 mA short-circuit protection (auto-recoverable), preventing damage if an actuator cable is accidentally grounded—unlike basic modules that require manual reset, reducing unplanned downtime by 40%.

Per-Channel Flexibility + Rugged Design: Motorola MVME215-3 allows each of its 8 channels to be configured for 4 different output ranges (±5V/±10V/0–5V/0–10V), adapting to diverse actuators—from low-voltage proportional valves (0–5V) to high-voltage variable-frequency drives (±10V). This eliminates the need for external signal scalers, cutting system costs. Its -20°C–70°C operating range and 2.0 g vibration resistance also exceed the Motorola MVME-224-2’s environmental specs, making it suitable for harsh environments like offshore oil platforms or automotive test cells.

Typical Application Scenarios

In chemical reactor closed-loop control, Motorola MVME215-3 is paired with Motorola MVME162-043 to regulate a 10,000-liter batch reactor. The host SBC receives temperature/pressure data from a Motorola MVME-224-2 (analog input module) and sends setpoints to Motorola MVME215-3: 4 channels control heating/cooling valves (0–10V), 2 channels adjust stirrer speed (±5V), and 2 channels regulate chemical feed pumps (0–5V). The module’s ±0.05% linearity ensures precise valve opening (e.g., 50% opening = 5.000V output), maintaining reactor temperature at 150°C ±0.5°C and pressure at 5 bar ±0.02 bar—critical for meeting ISO 9001 quality standards for chemical production.

For aerospace component testing, Motorola MVME215-3 serves as the actuator control module for a jet engine turbine test rig. It outputs 8 channels of ±10V signals to hydraulic actuators that simulate flight conditions (e.g., thrust, pitch, yaw). The module’s <10 µs settling time ensures actuators respond to test commands in real time, while its <5 ppm/°C drift maintains position accuracy (±0.01 mm) over 8-hour test runs. Motorola MVME215-3’s short-circuit protection also safeguards the module from damage if an actuator hydraulic line fails—protecting a $500,000+ test rig from costly downtime.

Motorola MVME215-3

Related Model Recommendations

Motorola MVME215-1: Entry-level variant of Motorola MVME215-3 with 4 AO channels. Suitable for small control systems (e.g., single-tank level control) where fewer actuators are needed.

Motorola MVME-224-2: Analog input module complementary to Motorola MVME215-3. Collects sensor data (e.g., temperature, pressure) for the host SBC, which uses Motorola MVME215-3 to adjust actuators—forming a closed-loop system.

Motorola MVME215-5: High-channel upgrade of Motorola MVME215-3 with 16 AO channels. Ideal for large-scale systems (e.g., 16-zone HVAC control) requiring extensive actuator control.

Motorola MVME-332: 128-channel digital I/O module. Works with Motorola MVME215-3 to add discrete control (e.g., actuator on/off, emergency stops) to analog-based systems.

Motorola MVME-050: Industrial power supply (±5V/±12V, 85–264 VAC). Powers Motorola MVME215-3 and ensures stable voltage for its precision reference, preventing output drift.

Motorola MVME-712-M: Digital output module. Complements Motorola MVME215-3 by providing high-current (2A) outputs for actuators that exceed the module’s 500 mA limit (e.g., large valves).

Emerson MVME215-3-R: Modernized replacement for Motorola MVME215-3 (Emerson rebranding) with Ethernet-based setpoint updates. Ideal for users migrating legacy VME systems to IP-controlled networks.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing Motorola MVME215-3, confirm the VMEbus chassis has a 3U slot and supports A16/D16 addressing. Verify the power supply provides ±5V/±12V (tolerance ±1%)—use a precision multimeter (0.01% accuracy) to avoid voltage ripple that causes output drift. Gather tools: anti-static wristband (to protect analog circuitry), torque screwdriver (0.3 N·m for chassis mounting), precision voltmeter (for calibration), and a laptop (for configuration via the host SBC). Use shielded twisted-pair cables (22 AWG minimum) for actuator connections—ground one end of the shield to the chassis to reduce EMI, and avoid parallel routing with power cables (minimum 15 cm separation).

Maintenance suggestions: For daily upkeep, check Motorola MVME215-3’s LEDs—steady power, green channel active LEDs, and no red fault LEDs indicate normal operation. Perform monthly software calibration using a 0.001% precision voltage reference to verify output accuracy—adjust gain/offset if deviations exceed ±0.05% full scale. Clean the module’s vents every 3 months with compressed air (20 PSI max) to prevent overheating. If a short-circuit fault occurs, isolate the actuator (check for cable damage) and reset the module via the host SBC—no physical replacement is needed. Store spare Motorola MVME215-3 units in anti-static bags (15°C–25°C, 40%–60% humidity) to preserve the voltage reference’s stability.

Service and Guarantee Commitment

Motorola MVME215-3 is backed by a 30-month warranty from Emerson, covering defects in materials (e.g., precision DAC chips, isolation transformers) and workmanship—longer than the 24-month warranty of the Motorola MVME-224-2. If a fault occurs, Emerson provides free 4-day replacement for in-stock units—critical for applications like pharmaceutical manufacturing where AO downtime halts batch production. For extended support, customers can purchase a 48-month service contract, including 24/7 technical support (phone/email), access to archived calibration software, and on-site troubleshooting for complex issues (e.g., drift compensation failures).

Emerson maintains a global stock of critical components for Motorola MVME215-3 (12-bit DACs, ultra-precision references) to support legacy users until 2038. Technical engineers specialize in analog output systems, offering remote calibration guidance and performance validation for critical applications (e.g., aerospace testing). This commitment ensures Motorola MVME215-3 remains a reliable solution for legacy VMEbus control systems, helping users avoid costly full-system upgrades while retaining precision actuator control.