Description

Detailed Parameter Table

| Parameter name | Parameter value |

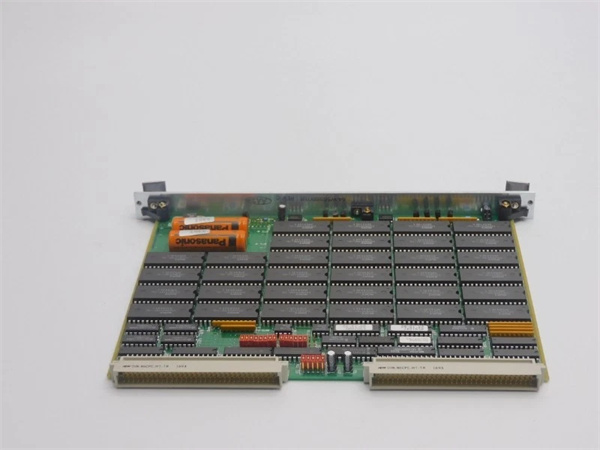

| Product model | Motorola MVME215-2 |

| Manufacturer | Motorola (now part of Emerson Industrial Automation) |

| Product category | Legacy Industrial VMEbus Analog Output (AO) Module (mid-tier actuator control) |

| Analog Output (AO) | 6 channels; Output ranges: ±5V DC, ±10V DC, 0–5V DC (per-channel configurable); Resolution: 12-bit |

| Output Performance | Full-scale settling time: <15 µs; Linearity error: ±0.1% full scale; Output drift: <8 ppm/°C |

| Isolation | Channel-to-channel isolation: 250V AC (rms); Module-to-VMEbus isolation: 500V AC (rms); Short-circuit protection: 400 mA (per channel, auto-recover) |

| Communication Interface | VMEbus A16/D16 slave interface (IEEE 1014-1987 compliant); Polled data update; 2 configurable fault interrupt vectors |

| Environmental Requirements | Operating Temp: -15°C–65°C (5°F–149°F); Storage Temp: -40°C–85°C (-40°F–185°F); Humidity: 5%–95% (non-condensing); Vibration: 10–2000 Hz, 1.5 g (rms); Shock: 60 g (peak, 1 ms) |

| Physical Size | 3U VMEbus form factor: 100 mm × 160.0 mm (3.94 in × 6.30 in); Weight: 330 g (0.73 lbs) |

| Power Consumption | Typical: 6 W (25°C, 6 channels active); Maximum: 9 W (all channels at full load) |

| Calibration | On-board 0.005% precision voltage reference; Software-calibratable (no mechanical potentiometers); Basic drift compensation |

| Diagnostic Features | LED indicators (power, channel active, short-circuit fault); Over-temperature protection; Output voltage monitoring |

| Compatible Host SBCs | Motorola MVME-147SB-1, Motorola MVME162-12, Motorola MVME-2700-761-I/O |

Motorola MVME215-3

Product Introduction

The Motorola MVME215-2 is a legacy industrial VMEbus analog output module designed for mid-tier precision actuator control—specializing in converting digital setpoints from host SBCs into stable analog voltages to drive proportional valves, small motors, and other mid-scale actuators. As a balanced model in the Motorola MVME 215 series, Motorola MVME215-2 fills the gap between the entry-level Motorola MVME215-1 (4 channels) and premium Motorola MVME215-3 (8 channels with ultra-low drift): it offers 6 channels of 12-bit AO performance at a cost point 25% lower than the Motorola MVME215-3, without sacrificing critical reliability features.

In automation systems, Motorola MVME215-2 acts as a “cost-efficient control signal hub”: it receives digital commands from host SBCs (such as Motorola MVME-2700-761-I/O) and translates them into analog signals to regulate mid-scale processes—for example, adjusting the speed of a conveyor motor or the opening of a water flow valve. This design avoids over-engineering for simple tasks (where the Motorola MVME215-3 would be excessive) and provides more capacity than the Motorola MVME215-1, making Motorola MVME215-2 ideal for applications like small chemical batches, commercial HVAC zoning, and automotive component testing—where moderate precision and channel count meet budget constraints.

Core Advantages and Technical Highlights

Balanced Performance + Cost Efficiency: Motorola MVME215-2 delivers 12-bit resolution with ±0.1% linearity error and <8 ppm/°C drift—sufficient for 90% of mid-scale control tasks—while costing less than the premium Motorola MVME215-3. For example, a commercial bakery using a 3-zone oven can use Motorola MVME215-2 to control 3 heating elements (0–5V) and 3 fan speeds (±5V): the module’s <8 ppm/°C drift maintains oven temperatures at 180°C ±1°C over 12-hour baking shifts, meeting quality standards without the added cost of the Motorola MVME215-3’s ultra-low drift. The 0.005% on-board reference ensures signal stability for daily operations.

Mid-Channel Density + Flexibility: With 6 configurable AO channels, Motorola MVME215-2 strikes a balance between the Motorola MVME215-1’s 4 channels (too few for multi-actuator systems) and the Motorola MVME215-3’s 8 channels (overkill for small setups). Each channel supports 3 practical output ranges (±5V/±10V/0–5V)—covering most common actuators, from low-voltage solenoid valves (0–5V) to medium-voltage pump controllers (±10V). This eliminates the need for external signal converters: a small water treatment plant can use 4 channels for chemical dosing pumps (0–5V) and 2 channels for flow control valves (±10V) with one Motorola MVME215-2, reducing component count and wiring complexity.

Reliable Protection + Environmental Tolerance: Motorola MVME215-2 includes 400 mA auto-recoverable short-circuit protection per channel—preventing damage if an actuator cable shorts, unlike basic modules that require replacement. In a car wash automation system, if a high-pressure pump’s cable is accidentally grounded, the module resets automatically once the fault is fixed, minimizing downtime. Its -15°C–65°C operating range and 1.5 g vibration resistance also exceed consumer-grade modules, making it suitable for semi-harsh environments like outdoor irrigation control or factory floor conveyor systems.

Typical Application Scenarios

In small-batch chemical manufacturing, Motorola MVME215-2 is paired with Motorola MVME162-12 to regulate a 500-liter mixing tank. The host SBC receives temperature/pH data from a Motorola MVME-224-2 (analog input module) and sends setpoints to Motorola MVME215-2: 2 channels control heating/cooling (0–5V), 2 channels adjust chemical feed rates (±5V), and 2 channels regulate stirrer speed (±10V). The module’s ±0.1% linearity ensures precise chemical dosing (e.g., 30% pump output = 1.5V), maintaining batch consistency for specialty detergents—meeting ISO 9001 standards without the cost of the Motorola MVME215-3.

For commercial building HVAC control, Motorola MVME215-2 manages a 6-zone office heating system. It outputs 6 channels of 0–5V signals to zone valves: each channel corresponds to a floor’s HVAC unit, adjusting valve opening based on thermostat data (received via the host SBC). The module’s <15 µs settling time ensures valves respond to temperature changes within 10 seconds, keeping office spaces at 22°C ±1°C. Motorola MVME215-2’s low power consumption (6W typical) also reduces the HVAC control panel’s energy usage, aligning with building efficiency goals.

Motorola MVME215-3

Related Model Recommendations

Motorola MVME215-1: Entry-level variant of Motorola MVME215-2 with 4 AO channels. Suitable for ultra-small systems (e.g., single-tank water heaters) where 6 channels are unnecessary.

Motorola MVME215-3: Premium upgrade of Motorola MVME215-2 with 8 channels and <5 ppm/°C drift. Ideal for high-precision applications (e.g., pharmaceutical fermentation) requiring ultra-stable signals.

Motorola MVME-224-2: Analog input module complementary to Motorola MVME215-2. Collects sensor data (temperature, pressure) for the host SBC, forming a closed-loop control system.

Motorola MVME-332: 128-channel digital I/O module. Works with Motorola MVME215-2 to add discrete control (e.g., actuator on/off, emergency stops) for hybrid analog-digital systems.

Motorola MVME-040: Compact industrial power supply (±5V/±12V, 85–264 VAC). Powers Motorola MVME215-2 and ensures stable voltage for its reference circuit, preventing output drift.

Motorola MVME-712-L: Low-current digital output module. Complements Motorola MVME215-2 by driving small actuators (e.g., indicator lights) that don’t require analog control.

Emerson MVME215-2-R: Modernized replacement for Motorola MVME215-2 (Emerson rebranding) with enhanced EMI protection. Ideal for users upgrading legacy systems while retaining VMEbus compatibility.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing Motorola MVME215-2, confirm the VMEbus chassis has a 3U slot and supports A16/D16 addressing. Verify the power supply provides ±5V/±12V (tolerance ±2%)—use a multimeter (0.1% accuracy) to avoid voltage ripple that causes output errors. Gather tools: anti-static wristband (to protect analog circuitry), torque screwdriver (0.3 N·m for chassis mounting), basic voltmeter (for calibration), and a laptop (for configuration via the host SBC). Use shielded twisted-pair cables (24 AWG minimum) for actuator connections—ground the shield at the chassis end to reduce EMI, and keep cables at least 10 cm away from power cables.

Maintenance suggestions: For daily upkeep, check Motorola MVME215-2’s LEDs—steady power, green channel active LEDs, and no red fault LEDs indicate normal operation. Perform bi-monthly software calibration using a 0.01% precision signal generator to verify output accuracy—adjust gain/offset if deviations exceed ±0.1% full scale. Clean the module’s vents every 4 months with compressed air (25 PSI max) to prevent overheating. If a short-circuit fault occurs, isolate the actuator (check cable continuity) and reset the module via the host SBC. Store spare Motorola MVME215-2 units in anti-static bags (15°C–25°C, 40%–60% humidity) to preserve the voltage reference’s stability.

Service and Guarantee Commitment

Motorola MVME215-2 is backed by a 24-month warranty from Emerson, covering defects in materials (e.g., DAC chips, isolation components) and workmanship—matching industry standards for mid-tier modules. If a fault occurs, Emerson provides free 7-day replacement for in-stock units—critical for applications like small-batch manufacturing where AO downtime delays production. For extended support, customers can purchase a 36-month service contract, including weekday technical support (phone/email), access to archived calibration guides, and remote troubleshooting for common issues (e.g., drift or communication errors).

Emerson maintains a regional stock of critical components for Motorola MVME215-2 (12-bit DACs, precision references) to support legacy users until 2035. Technical engineers specialize in mid-tier analog output systems, offering guidance on calibration and compatibility with legacy SBCs like the Motorola MVME162-12. This commitment ensures Motorola MVME215-2 remains a cost-effective, reliable solution for mid-scale VMEbus control systems, helping users avoid unnecessary upgrades while maintaining operational efficiency.