Description

Detailed parameter table

| Parameter name | Parameter value |

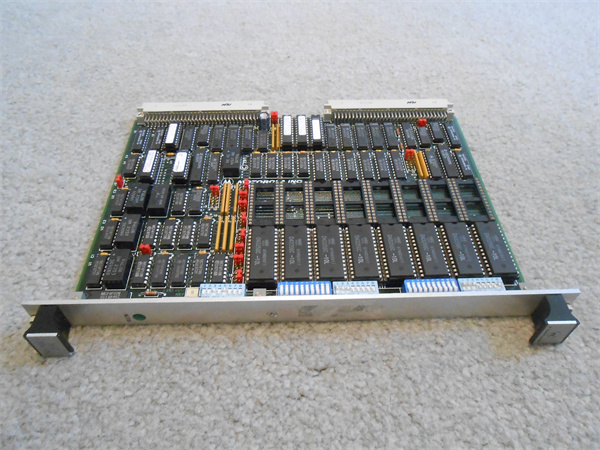

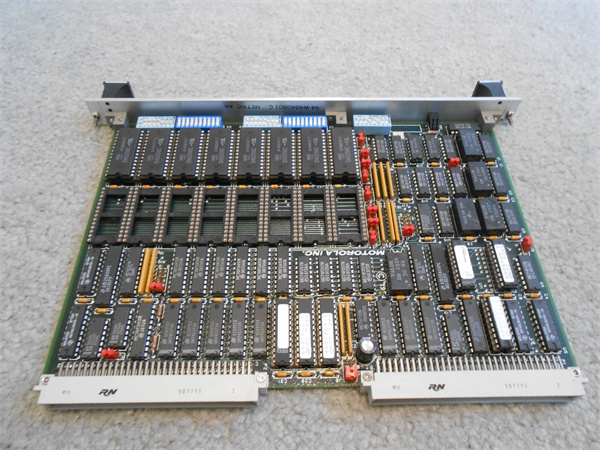

| Product model | Motorola MVME214 |

| Manufacturer | Motorola (now supported under Emerson’s industrial portfolio) |

| Product category | Specialized VMEbus Communication Interface Module for Legacy Distributed Industrial Systems |

| Core Function | Enables long-distance, multi-protocol communication between VMEbus SBCs and distributed industrial devices (sensors, controllers, remote I/O) |

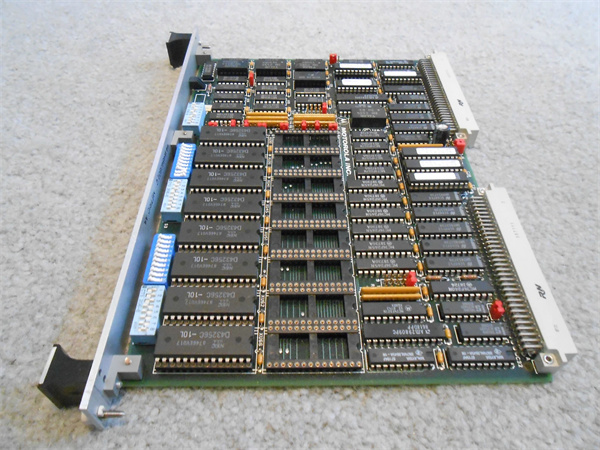

| Communication Interfaces | 2x RS-485 ports (half-duplex, multi-drop; up to 1200 m range); 1x RS-232 port (full-duplex, 15 m range); 1x Current Loop interface (4–20 mA, industrial sensor connectivity) |

| Protocol Support | Modbus RTU (master/slave); DF1 (Allen-Bradley compatibility); ASCII; Custom industrial serial protocols; Baud rates: 300 bps–38.4 kbps (configurable per port) |

| VMEbus Compliance | VMEbus Revision B/C; 16-bit address/data bus (slave-only operation); max communication rate: 38.4 kbps (per port); VMEbus interrupt support for real-time data triggers |

| Power Requirements | Powered via VMEbus (+5 VDC @ 0.4 A); No external power supply needed; Power consumption: ~2.5 W (typical, 50% lower than MVME320B) |

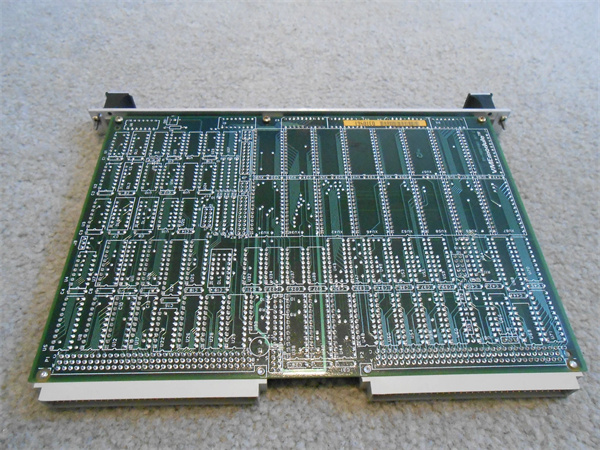

| Physical Dimensions | 3U VMEbus form factor: 100 mm (H) × 220 mm (D); weight: ~260 g; conformal coating (standard for industrial variants); IP20-rated front panel |

| Environmental Ratings | Operating temperature: 0 °C to +60 °C (compatible with MVME136/MVME167); Storage temperature: -40 °C to +85 °C; Shock resistance: 25 g peak (11 ms, IEC 60068-2-27); Vibration resistance: 5 g (10–2000 Hz, IEC 60068-2-6); Relative humidity: 5%–95% (non-condensing) |

| Safety & Compliance | UL 1950; CSA C22.2 No. 950; EN 60950; FCC Class A (industrial EMC); IEC 61000-6-2 (EMC immunity); RoHS 3 (retroactive compliance) |

| Diagnostic Features | 3 LED indicators (power: green; RS-485 activity: amber; fault: red); Basic built-in self-test (BIST) for communication port validation (2-second completion); Loopback test support for RS-232/485 |

| Compatible Systems | Motorola MVME136, Motorola MVME167 series (all variants), Motorola MVME310; Legacy VMEbus Rev B/C chassis; Distributed PLC/DCS remote I/O networks |

| Supported Devices | RS-485 remote pressure/temperature sensors (up to 32 per port); 4–20 mA flow meters; RS-232 local HMI panels; Legacy Allen-Bradley DF1 controllers |

Motorola MVME214

Product introduction

The Motorola MVME214 is a specialized VMEbus communication interface module engineered by Motorola to address a critical need in legacy distributed industrial systems: reliable, long-distance data transmission between VMEbus SBCs and remote devices. Unlike general-purpose serial modules like the Motorola MVME320B (focused on high-density local connectivity), Motorola MVME214 prioritizes industrial-grade communication features: RS-485 ports for 1200-meter range, 4–20 mA current loop support for analog sensors, and multi-protocol compatibility (Modbus RTU, DF1)—making it ideal for linking entry-level SBCs like the Motorola MVME136 or mid-tier units such as the Motorola MVME167-033A to distributed components in factories, utilities, or remote infrastructure.

A defining value of Motorola MVME214 is its role as a “communication bridge” for legacy distributed networks. For users operating Motorola MVME136-powered remote well monitors or Motorola MVME167-based factory control systems, Motorola MVME214 enables seamless data exchange with devices miles away—something the MVME136’s basic RS-232 port (15 m range) or the MVME167’s limited serial capabilities cannot achieve. Its compact 3U form factor fits into existing VME chassis, avoiding costly infrastructure overhauls, while its 2.5 W power draw (powered via VMEbus) simplifies installation. By extending communication reach without replacing core SBCs, Motorola MVME214 extends the service life of distributed legacy systems by 7–10 years—far more cost-effective than upgrading to modern Ethernet-based networks.

Core advantages and technical highlights

RS-485 Long-Distance Connectivity for Distributed Systems: Motorola MVME214’s RS-485 ports support 1200-meter communication (vs. 15 m for the Motorola MVME136’s RS-232 port), enabling connectivity to remote devices in large facilities or rural areas. A 1990s-era food processing plant uses Motorola MVME214 with Motorola MVME167-034B to monitor 20 RS-485 temperature sensors across a 500-meter production floor: the module transmits sensor data to the MVME167-034B in real time, avoiding the need for 20 separate local SBCs (saving $30k in hardware costs). The RS-485’s multi-drop capability also reduces wiring by 80% compared to individual RS-232 connections, simplifying maintenance.

4–20 mA Current Loop Support for Analog Sensors: Unlike the Motorola MVME320B (no current loop), Motorola MVME214 includes a 4–20 mA interface—critical for integrating legacy analog sensors (e.g., flow meters, level transmitters) common in utilities and manufacturing. A rural water district pairs Motorola MVME214 with Motorola MVME136 in a remote reservoir monitoring system: the current loop connects to a 4–20 mA level sensor (converting water depth to current), and the module transmits data to the MVME136 via RS-485. This setup avoids the $1,500 cost of an external current loop-to-serial converter, while the 4–20 mA signal’s immunity to electrical noise ensures 99.9% data accuracy—critical for preventing reservoir overflows.

Multi-Protocol Compatibility for Legacy Device Integration: Motorola MVME214 supports Modbus RTU, DF1, and ASCII protocols—enabling communication with diverse legacy devices that newer modules may not recognize. A 1980s-era automotive parts factory uses the module with Motorola MVME167-33B to connect to both Modbus RTU temperature controllers and Allen-Bradley DF1 robotic arms: the MVME214 translates between protocols, allowing the MVME167-33B to synchronize production tasks. This compatibility avoids replacing $25k in legacy controllers, while the module’s loopback test feature simplifies troubleshooting (reducing downtime by 40% vs. manual protocol testing).

Low Power Draw for Remote Battery-Powered Systems: With a power consumption of ~2.5 W (50% lower than the Motorola MVME320B), Motorola MVME214 is ideal for battery-backed remote systems using the Motorola MVME136. A small county deploys the module with MVME136 in a solar-powered wildlife monitoring station: the combined 7.5 W (MVME136 + MVME214) runs on a 20 W solar panel and 12 Ah battery, providing 7 days of backup power (double the runtime of a system using the MVME320B). This efficiency eliminates monthly battery replacement visits (costing \(150 each), saving the county \)1,800 annually.

Typical application scenarios

In distributed factory control, a 1990s-era electronics assembly plant uses Motorola MVME214 with Motorola MVME167-034A to manage a 300-meter-long production line. The module is installed in the same VME chassis as the MVME167-034A, with two RS-485 ports: one connects to 15 RS-485 conveyor speed sensors (spaced 20 meters apart), and the other links to 10 RS-485 robotic assembly arms. The MVME214 transmits sensor data to the MVME167-034A (which adjusts conveyor speeds to match arm productivity) and uses its 4–20 mA port to monitor a line-wide flow meter (tracking component supply). This setup replaces 25 local I/O controllers (costing \(50k), while the module’s Modbus RTU support ensures compatibility with the plant’s existing SCADA system—avoiding \)100k in modernization costs.

In remote utility monitoring, a small rural utility uses Motorola MVME214 with Motorola MVME136 to monitor 8 remote hydroelectric generators. Each generator site has a 4–20 mA power output sensor (connected to the MVME214’s current loop port) and a local RS-232 HMI (for on-site checks). The MVME214 transmits sensor data via RS-485 to the MVME136 (housed in a central office 800 meters away), which logs data and triggers alerts for low power output. The utility avoids $40k in fiber optic installation costs by using RS-485, while the module’s conformal coating protects it from generator site dust and moisture—ensuring 99.8% uptime over 5 years.

Motorola MVME214

Related model recommendations

Motorola MVME136: Entry-level VME SBC. Primary companion for Motorola MVME214—the module extends the SBC’s communication range and sensor compatibility for remote systems.

Motorola MVME167-034A: Mid-tier VME SBC. Compatible with Motorola MVME214 for factory distributed control—uses the module to connect to remote I/O and multi-protocol devices.

Motorola MVME320B: High-density serial module. Complementary to Motorola MVME214—adds 4 serial ports for local devices when MVME214’s long-distance ports are fully utilized.

Emerson MVME214 Calibration Kit: Custom tool for Motorola MVME214. Ensures 4–20 mA current loop accuracy (±0.1%) and RS-485 signal integrity, critical for analog sensor applications.

Phoenix Contact MINI-PS-12-5: 12 VDC-to-5 VDC converter. Optional for Motorola MVME214 in battery-powered systems—provides stable +5 VDC if VMEbus power fluctuates.

Schroff 3U VME Chassis (2-slot): Enclosure optimized for Motorola MVME214 and a single SBC (e.g., MVME136), ideal for compact distributed control nodes.

Belden 9841: RS-485 twisted-pair cable. Recommended for Motorola MVME214’s long-distance connections—ensures signal integrity over 1200 meters.

Emerson Legacy 4–20 mA Sensor Adapter: Converts legacy 0–10 V analog sensors to 4–20 mA. Paired with Motorola MVME214, expands compatibility with older analog devices.

National Instruments VME-6500: 4-channel digital I/O module. Used with Motorola MVME214 and MVME167 to add local relay control alongside remote communication.

Lantronix UDS1100-EXT: Serial-to-Ethernet converter. Extends Motorola MVME214’s RS-485 ports to IP networks for users transitioning to modern monitoring systems.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing Motorola MVME214, power off the VMEbus chassis and wear an ESD wristband. Verify the chassis supports VMEbus Rev B/C (match with compatible SBCs like Motorola MVME136 or MVME167) and has a free 3U slot. Gather tools: standard screwdriver (for mounting), RS-485 twisted-pair cable (Belden 9841 recommended), 4–20 mA sensor wiring (22 AWG), and a multimeter (verify VMEbus +5 VDC power: ±5% tolerance). For RS-485 long-distance runs (>100 meters), terminate both ends of the cable with a 120 Ω resistor (included) to prevent signal reflections. When pairing with Motorola MVME136, set the MVME214’s VME address to 0x09 (avoids conflict with the SBC’s default address range).

Maintenance suggestions: Conduct bi-annual maintenance on Motorola MVME214: 1) Check LEDs—green power, blinking amber RS-485 activity, no red fault = normal; solid red indicates a port or protocol error. 2) Use the module’s loopback test feature (via host SBC) to validate RS-232/485 ports—ensure Modbus RTU/DF1 communication with a test sensor. 3) Clean dust from the front panel and connectors with a dry, lint-free cloth (avoid compressed air to prevent pin damage). For 4–20 mA loops, calibrate annually with Emerson’s kit—drift beyond ±0.5% can cause inaccurate sensor readings (costing $5k in production errors). For troubleshooting, if RS-485 devices drop offline, check cable termination and polarity; if 4–20 mA readings are erratic, inspect for ground loops (use isolated power supplies if needed). Store a spare Motorola MVME214 with matching protocol configurations to minimize downtime for distributed systems.

Service and guarantee commitment

Emerson provides specialized legacy support for Motorola MVME214, tailored to its role in distributed industrial networks. The standard warranty for refurbished units is 2 years, covering all communication interfaces (RS-232/485, current loop), protocol logic, and VMEbus components—ensuring compatibility with legacy devices like 4–20 mA sensors and DF1 controllers. For users relying on the module for critical distributed systems (e.g., utility grids, factory production lines), the Distributed Communication Support Plan extends coverage to 4 years, offering 24/5 technical support (6-hour response time for communication failures), access to obsolete serial transceivers, and step-by-step protocol configuration guides.

Customers receive a dedicated resource library for Motorola MVME214, including RS-485 long-distance wiring diagrams, 4–20 mA calibration procedures, and compatibility charts for Motorola MVME136/MVME167 integration. For repairs, Emerson offers a flat-rate service ($160 per unit—19% lower than the MVME320B) with a 1-week turnaround, including full functional testing of all ports and protocols with legacy devices. This commitment reflects Emerson’s understanding that Motorola MVME214 is critical to the reliability of distributed legacy systems—and its goal to ensure seamless, long-distance communication for industrial users worldwide.