Description

Detailed Parameter Table

| Parameter name | Parameter value | Note |

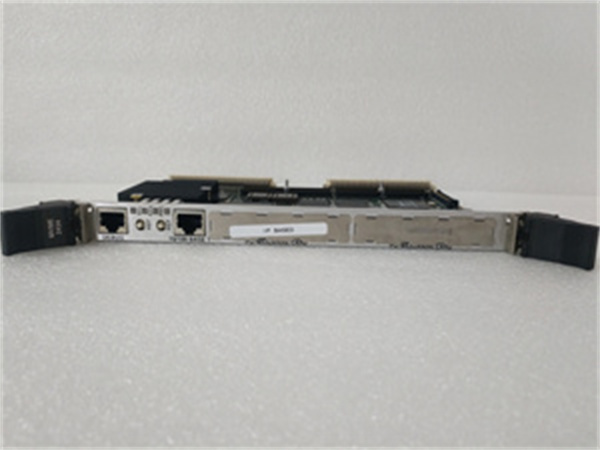

| Product model | Motorola MVME2100 Series | Including MVME2100-1 sub-model |

| Manufacturer | Motorola (Emerson) | Currently supported by Emerson’s industrial computing division |

| Product category | VMEbus Single Board Computer (SBC) | Compliant with VME64 bus standard |

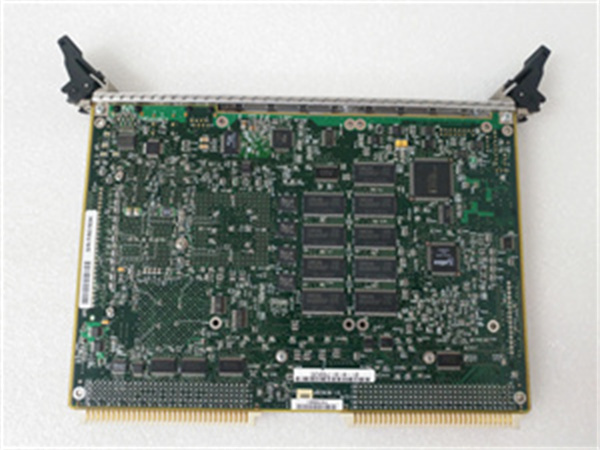

| Microprocessor | MPC8240 (200MHz for MVME2100-1); PowerPC 603e (166MHz for base model) | Dual-core architecture with integrated memory controller |

| Memory configuration | 16-256MB DRAM; 295KB additional flash memory; 630KB nonvolatile memory | ECC support unconfirmed in public specs |

| Expansion capability | 1×PMC slot; 1×PC-MIP mezzanine slot; dual Ethernet ports; RS232 printer port | Supports remote I/O (RIO) communication |

| Physical dimensions | Single-slot VME form factor; weight: 1.8kg | Hot-swappable design option |

| Environmental requirements | Wide temperature version: -40°C~+85°C (operation), -55°C~+95°C (storage); Standard version: 0°C~+70°C (operation); Humidity: 5%~95%RH (non-condensing); Protection level: IP65/IP67 | Complies with MIL-STD-810G vibration standard |

| Power supply | Input voltage: 35~269V AC, 48~67Hz; 89-280V AC alternative | Industrial-grade power regulation |

Motorola MVME2434

Product Introduction

The **Motorola MVME2100 Series** is a highly modular VMEbus single-board computer designed for mission-critical industrial control applications. Positioned as a reliable mid-range solution between entry-level controllers and high-performance systems like the MVME2400, it balances computing power, expandability, and environmental ruggedness. At its core lies either the PowerPC 603e (166MHz) or MPC8240 (200MHz for MVME2100-1) processor, both featuring integrated memory controllers and PCI interfaces that optimize data transfer between on-board peripherals and external devices.

Distinguished by its industrial-grade component selection and robust design, the MVME2100 excels in harsh operating environments. The board’s flexible expansion architecture—including PMC/PC-MIP slots and dual Ethernet ports—enables seamless integration with specialized I/O modules for analog/digital conversion, communication protocols, and image processing. This versatility makes it a preferred choice for legacy system upgrades and new installations across multiple industries requiring stable, long-term operation.

Core Advantages and Technical Highlights

Dual-processor platform options: The MVME2100 offers configurable computing power through two processor variants. The MPC8240-based MVME2100-1 delivers 200MHz performance for data-intensive tasks like radar signal processing, while the 166MHz PowerPC 603e model provides cost-effective solutions for standard control applications. Both processors feature 32-bit data paths and efficient instruction execution optimized for real-time control algorithms.

Extreme environmental adaptability: With wide-temperature versions operating from -40°C to +85°C and IP67 protection (select models), the MVME2100 withstands extreme temperatures, humidity, and physical contaminants. This ruggedness is validated by compliance with MIL-STD-810G vibration standards, making it suitable for offshore drilling platforms, desert industrial sites, and military vehicles.

Flexible I/O expansion: The combination of PMC and PC-MIP mezzanine slots supports customization with specialized interface cards, including motion control modules, high-speed data acquisition cards, and communication adapters. Dual Ethernet ports enable simultaneous connection to control networks and management systems, while remote I/O capability extends monitoring reach across distributed industrial facilities.

Legacy system compatibility: Designed with backward compatibility in mind, the MVME2100 supports multiple operating systems and software environments commonly used in industrial automation. Its VME64 bus architecture ensures seamless integration with existing VME-based infrastructures, reducing upgrade costs for plants with established control systems.

Typical Application Scenarios

In **industrial automation**, the MVME2100 serves as the core controller for PLC systems, production line monitoring, and factory automation networks. Its dual Ethernet ports facilitate separation of control and information layers, while the rugged design ensures uninterrupted operation in dusty or temperature-fluctuating environments. For example, in automotive manufacturing plants, it manages robotic assembly lines with sub-millisecond response times.

Within **process control** industries (oil & gas, chemical processing), the wide-temperature variant (-40°C~+85°C) monitors critical parameters like pressure, temperature, and flow rates. Its IP67 protection enables deployment in wet or corrosive environments, such as offshore oil rigs where equipment must withstand saltwater exposure.

In **military electronics**, the MVME2100-1 handles radar signal processing and image recognition tasks, leveraging the 200MHz MPC8240 processor’s computational power. Its compliance with military vibration standards ensures reliability in airborne or ground-based defense systems.

**Medical equipment** applications include diagnostic imaging systems and patient monitoring devices, where the board’s stable processing and expandable I/O support high-resolution image acquisition and real-time data analysis. The nonvolatile memory preserves critical patient data during power interruptions.

Model Comparison and Variant Information

| Model | Processor | Key Features | Target Application |

| MVME2100 (Base) | 166MHz PowerPC 603e | Standard temperature range, basic I/O configuration | General industrial control, factory automation |

| MVME2100-1 | 200MHz MPC8240 | Enhanced computing power, extended temperature option | Military electronics, high-speed data processing |

| MVME2400 Series | 233-350MHz PowerPC 750 | Dual PMC slots, ECC memory, higher performance | Aerospace, mission-critical industrial systems |

Motorola MVME2434

Installation and Maintenance Guidelines

Installation notes: The MVME2100’s single-slot VME form factor simplifies integration into standard VME chassis. Hot-swappable variants allow replacement without system shutdown, minimizing downtime in continuous-process applications. Ensure proper grounding during installation to prevent electrostatic discharge damage. For wide-temperature operation, verify chassis cooling meets -40°C to +85°C requirements with forced-air convection.

Maintenance recommendations: Periodically inspect Ethernet and I/O connectors for corrosion, especially in high-humidity environments. Monitor nonvolatile memory usage to prevent data overflow. When upgrading firmware, use Emerson’s official configuration tools to ensure compatibility with legacy software. For IP67-rated units, avoid disassembly in dusty environments to maintain ingress protection.

Service and Support Information

While Motorola has transitioned industrial computing support to Emerson, technical documentation and firmware updates for the MVME2100 remain available through Emerson’s support portal. Authorized service providers like深圳长欣自动化设备有限公司 (Shenzhen Changxin Automation) offer repair services and spare parts for legacy units. Extended warranty contracts are recommended for critical applications, providing priority technical support and accelerated replacement turnaround.

For customers planning system modernization, Emerson offers migration paths to newer VMEbus or PCIe-based platforms that maintain software compatibility with MVME2100 applications, ensuring investment protection while leveraging advanced computing capabilities.