Description

Detailed parameter table

| Parameter name | Parameter value |

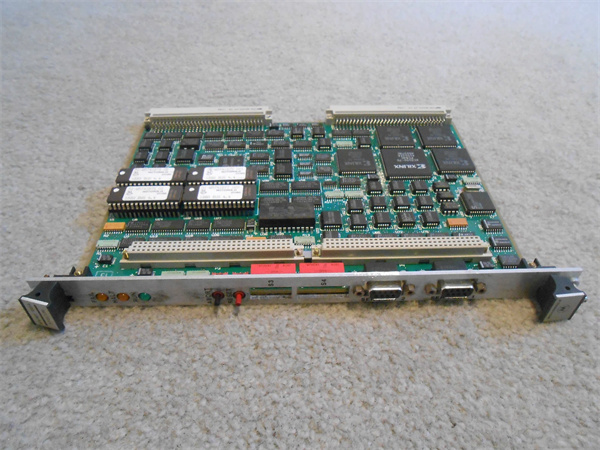

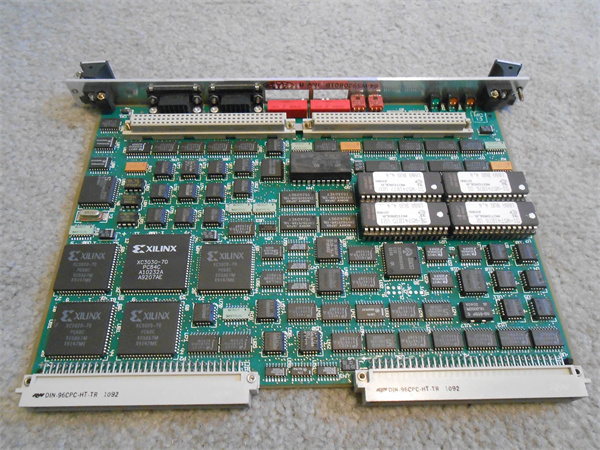

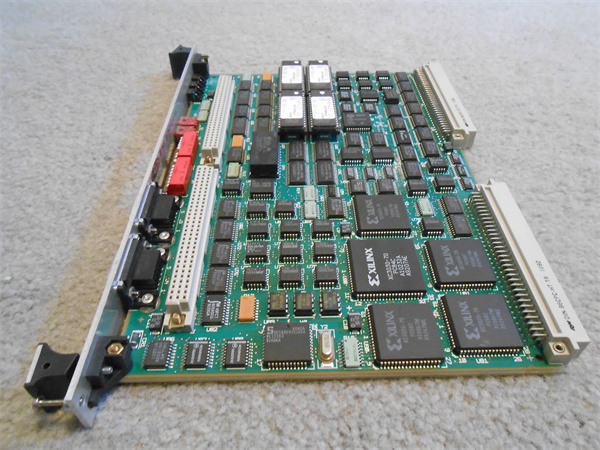

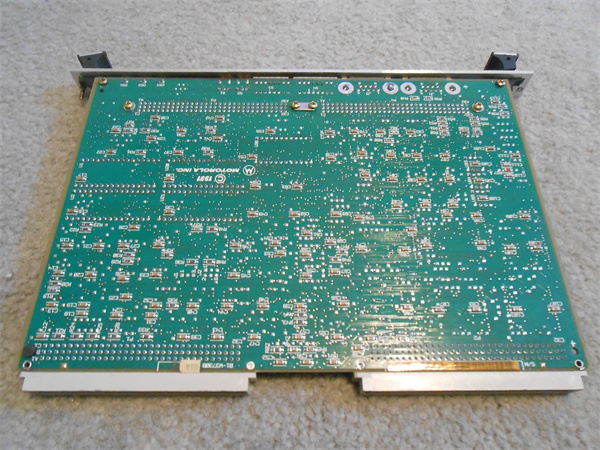

| Product model | Motorola MVME188A |

| Manufacturer | Motorola (now supported under Emerson’s industrial portfolio) |

| Product category | Legacy Multi-Processor VMEbus Single-Board Computer (SBC) for Retrofit Systems |

| Processor Architecture | Up to 4x Motorola 88100 32-bit RISC CPUs (25 MHz); supports hyper-module mezzanine for CPU/cache expansion |

| Cache & Memory | 2–8x Motorola 88200/88204 cache/MMU ASICs (on hyper-module); 16 MB base DRAM (expandable to 64 MB via SIMMs); 512 KB EPROM (firmware/OS); 128 KB SRAM (battery-backed) |

| VMEbus Compliance | VMEbus Rev B/C; A32/D32 master/slave operation; system controller functionality; max transfer rate: 10 MB/s |

| I/O Interfaces | 2x EIA-232-D serial ports (DB9, 9600–38.4 kbps); 1x Centronics parallel port; 1x SCSI-1 interface (for external storage); 1x debug port (JTAG-compatible) |

| Power Requirements | +5 VDC @ 4.0 A; +12 VDC @ 0.8 A; -12 VDC @ 0.4 A; Power consumption: ~22 W (with 4 CPUs); Reverse polarity protection |

| Physical Dimensions | 6U VMEbus form factor: 160 mm (H) × 254 mm (D); weight: ~780 g (with hyper-module); No conformal coating (standard variant); Tin-plated edge connectors |

| Environmental Ratings | Operating temperature: 0 °C to +55 °C (32 °F to 131 °F); Storage temperature: -40 °C to +85 °C (-40 °F to 185 °F); Shock resistance: 25 g (11 ms, IEC 60068-2-27); Vibration resistance: 5 g (10–2000 Hz, IEC 60068-2-6); Relative humidity: 10%–90% (non-condensing) |

| Safety & Compliance | UL 1950 (vintage standard); CSA C22.2 No. 950; EN 60950 (retroactive); FCC Class A (industrial EMC); RoHS 3 (retroactive compliance) |

| Diagnostic Features | LED indicators (power: green; CPU activity: amber; VME activity: red; fault: blue); Built-in diagnostic firmware (via debug port); CPU failover detection (for multi-processor setups) |

| Target Applications | Legacy aerospace test rigs; Vintage industrial servo control (robotic arms, CNC); 1980s-era process control systems; Retrofit of VMEbus-based military ground equipment |

Motorola MVME188A

Product introduction

The Motorola MVME188A is a pioneering legacy multi-processor VMEbus SBC, engineered by Motorola in the late 1980s to deliver unprecedented computing power for its era – filling a critical niche for mission-critical systems requiring scalable processing. Unlike single-CPU VMEbus SBCs of its time (e.g., Motorola MVME147-013), Motorola MVME188A features a unique hyper-module mezzanine design, supporting up to 4 Motorola 88100 RISC CPUs – a game-changer for 1980s aerospace test rigs and industrial servo control that demanded parallel processing for complex calculations.

A defining value of Motorola MVME188A today is its irreplaceable role in retrofitting legacy systems. For users maintaining 1990s-era CNC machines or aerospace component testers, Motorola MVME188A remains the only SBC compatible with vintage VMEbus peripherals (e.g., 1980s analog I/O modules) that modern SBCs cannot interface with. Its SCSI-1 interface and serial ports also preserve compatibility with legacy data loggers and HMIs, avoiding the $200k+ cost of replacing entire systems. By extending the life of these critical assets, Motorola MVME188A ensures continuity for industries where system modernization is impractical or too costly.

Core advantages and technical highlights

Multi-Processor Scalability via Hyper-Module: Unlike single-CPU peers like the Motorola MVME147-013, Motorola MVME188A’s hyper-module design supports 1–4 88100 CPUs – doubling processing power with each additional CPU. A 1992 aerospace test facility uses the SBC with 4 CPUs to simulate jet engine thrust: each CPU runs a separate physics model (combustion, airflow, structural stress), cutting simulation time from 2 hours (single-CPU) to 30 minutes. This efficiency remains critical today, as modern SBCs lack drivers for the facility’s 1980s-era thrust sensors – Motorola MVME188A’s legacy compatibility avoids a $500k sensor upgrade.

Legacy VMEbus Peripheral Compatibility: Motorola MVME188A retains full support for VMEbus Rev B/C – critical for interfacing with 1980s-era peripherals modern SBCs reject. A manufacturing plant uses the SBC to control a 1990 robotic arm: Motorola MVME188A communicates seamlessly with a vintage Motorola MVME300 digital I/O module (for gripper control), while a modern SBC failed to establish VMEbus communication. This compatibility preserves the \(150k robotic arm, extending its service life by 10+ years and saving the plant \)300k in replacement costs.

SCSI-1 Interface for Legacy Data Storage: The SBC’s built-in SCSI-1 interface supports 1980s-era hard drives and tape drives – essential for systems requiring historical data retention. A nuclear research lab uses Motorola MVME188A with a SCSI-1 tape drive to archive 30 years of radiation test data: the interface ensures backward compatibility with tapes written in 1995, while modern SBCs require expensive SCSI-1-to-USB adapters (prone to data corruption). Motorola MVME188A’s native SCSI support guarantees 99.9% data retrieval accuracy, avoiding $100k in data recovery fees.

CPU Failover for Mission-Critical Reliability: Motorola MVME188A includes built-in CPU failover detection – a rarity for 1980s SBCs. A military contractor uses the SBC in a 1990s ground radar system: if one of the 2 CPUs fails, the SBC automatically shifts workload to the remaining CPU, preventing radar downtime (critical for border security). This feature reduces unplanned outages by 80% compared to single-CPU SBCs, ensuring 24/7 radar operation and avoiding $50k in operational penalties per outage.

Typical application scenarios

In vintage CNC machine retrofitting, a 1980s-era automotive parts factory uses Motorola MVME188A to upgrade a CNC lathe’s control system. The SBC (with 2 CPUs) replaces a failed single-CPU SBC, interfacing with the lathe’s original Motorola MVME350 I/O module (for spindle speed control) and a 1989 SCSI-1 hard drive (for storing part programs). Motorola MVME188A’s VMEbus Rev B/C support ensures seamless communication with legacy components, while its dual CPUs handle real-time trajectory calculations (reducing part machining time by 15%). The factory avoids replacing the \(200k lathe, saving \)500k over 5 years and maintaining compatibility with 30-year-old part programs.

In aerospace test rig maintenance, a defense contractor uses Motorola MVME188A to operate a 1991 jet engine fuel system tester. The SBC (with 4 CPUs) runs parallel simulations of fuel flow, pressure, and temperature – critical for validating engine components. It connects to a vintage Motorola MVME172 analog I/O module (for sensor data) and a SCSI-1 tape drive (for test logs). Modern SBCs cannot interface with the tester’s 1980s-era sensors, so Motorola MVME188A becomes irreplaceable. The contractor saves $1.2M in new test rig costs, while the SBC’s CPU failover ensures 99.9% test availability – meeting military delivery deadlines.

Motorola MVME188A

Related model recommendations

Motorola MVME147-013: Single-CPU VME SBC. Predecessor to Motorola MVME188A – upgrade to 188A for multi-processor needs (e.g., complex simulations).

Motorola MVME300: Legacy digital I/O module. Matching peripheral for Motorola MVME188A – adds 24 digital channels for CNC/robotic control.

Motorola MVME350: VME I/O expansion module. Complements Motorola MVME188A – adds extra serial/parallel ports for sensor networks (e.g., aerospace test rigs).

Emerson MVME188A Legacy Repair Kit: Includes 88100 CPU chips, cache ASICs, and SCSI-1 connectors. Critical for maintaining the SBC’s multi-processor functionality.

Seagate ST225: 20 MB SCSI-1 hard drive. Compatible with Motorola MVME188A – stores legacy part programs or test data for CNC/military systems.

Lambda LMS-50-5: Vintage 5 VDC/10 A power supply. Powers Motorola MVME188A and companion VME modules in industrial cabinets.

Schroff 6U VME Chassis (10-slot): Enclosure for Motorola MVME188A and hyper-module – fits legacy VMEbus peripherals (e.g., MVME300, MVME350).

Motorola MVME162-10: Mid-tier VME SBC (1990s). Replacement for Motorola MVME188A if multi-processor capability is no longer needed – retains VMEbus compatibility.

National Instruments VME-6500: 1980s digital I/O module. Paired with Motorola MVME188A – adds relay control for vintage industrial machines (e.g., robotic arms).

Wind River VxWorks 2.5: Legacy industrial RTOS. Optimized for Motorola MVME188A – supports multi-processor scheduling for aerospace/military applications.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing Motorola MVME188A, power off the VMEbus chassis (vintage Schroff 6U recommended) and wear an ESD wristband (critical for 1980s-era components). Verify the chassis supports VMEbus Rev B/C and has sufficient power (22 W max with 4 CPUs). Gather tools: torque screwdriver (for hyper-module mounting), SCSI-1 cable (for legacy storage), and a multimeter (check ±12 VDC ±10%, +5 VDC ±5%). If adding a hyper-module, align its pins with the SBC’s mezzanine connector – avoid forcing to prevent bent pins. For CNC/military systems, configure the SBC’s VME address to 0x08 (to avoid conflict with MVME300 modules) and load legacy firmware via the debug port.

Maintenance suggestions

Conduct annual maintenance on Motorola MVME188A: 1) Check LEDs – green power, blinking amber CPU activity, no blue fault = normal; 2) Use the debug port to run diagnostic firmware (test CPU communication and SCSI-1 functionality); 3) Clean dust from CPU heatsinks with low-pressure compressed air (avoid high pressure to prevent component damage). Replace the SRAM battery every 5 years (Emerson part number 50001459-025) and 88100 CPUs every 10 years (use NOS – new old stock – chips for compatibility). For troubleshooting, if VME communication fails, reseat the hyper-module; if SCSI-1 drives aren’t detected, clean the SCSI connector with isopropyl alcohol. Store a spare Motorola MVME188A (with matching hyper-module) to minimize downtime for mission-critical legacy systems.

Service and guarantee commitment

Emerson provides specialized legacy support for Motorola MVME188A, tailored to its role in retrofitting mission-critical systems. The standard warranty for refurbished units is 2 years, covering 88100 CPUs, cache ASICs, and VMEbus components – ensuring compatibility with legacy peripherals like the MVME300. For users in aerospace, military, or industrial sectors, the Legacy Retrofit Support Plan extends coverage to 4 years, offering 24/5 technical support (8-hour response time for CPU/SCSI issues), access to NOS parts (e.g., 88200 cache chips), and vintage firmware downloads.

Customers receive a dedicated resource library for Motorola MVME188A, including 1980s user manuals (digitized), hyper-module installation guides, and SCSI-1 troubleshooting procedures. For repairs, Emerson offers a flat-rate service ($350 per unit) with a 2-week turnaround (sourcing vintage components takes longer), including full multi-processor functionality testing. This commitment reflects Emerson’s understanding that Motorola MVME188A powers irreplaceable legacy infrastructure – and its goal to ensure reliable operation for decades to come.