Description

Detailed parameter table

| Parameter name | Parameter value |

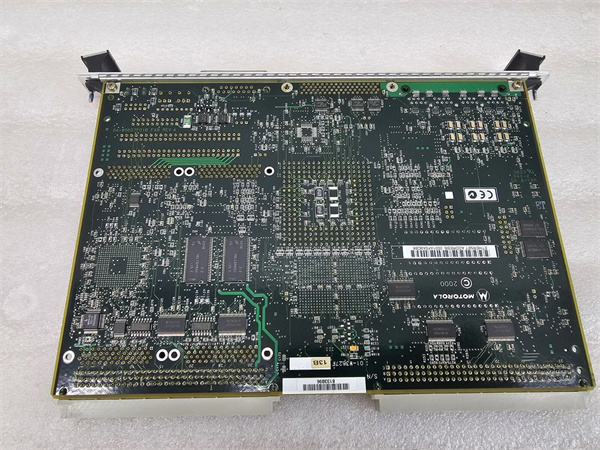

| Product model | Motorola MVME172PA-644SE |

| Manufacturer | Motorola (now supported under Emerson’s industrial portfolio) |

| Product category | High-Performance VMEbus Single-Board Computer (SBC) for Demanding Legacy Industrial Control |

| Processor Architecture | Motorola PowerPC 750FX 600 MHz RISC CPU; integrated floating-point unit (FPU); 256 KB L2 cache |

| Memory Configuration | 256 MB DDR SDRAM (expandable to 1 GB via DIMM slots); 16 MB Flash EPROM (firmware/OS); 512 KB SRAM with 10-year lithium battery backup |

| VMEbus Compliance | VMEbus Revision D; 32-bit/64-bit address/data bus (master/slave operation); maximum transfer rate: 80 MB/s |

| I/O Interfaces | 2x Gigabit Ethernet ports (RJ45, TCP/IP); 4x RS-232/422/485 serial ports (DB9, configurable); 1x SCSI-3 interface (for external storage); 1x PCI Express x1 slot; 1x VGA video port |

| Power Requirements | +5 VDC @ 4.5 A; +12 VDC @ 1.8 A; -12 VDC @ 0.3 A; Power consumption: ~28 W (typical) |

| Physical Dimensions | 6U VMEbus form factor: 160 mm (H) × 254 mm (D); weight: ~580 g; conformal coating (standard for industrial variants) |

| Environmental Ratings | Operating temperature: -40 °C to +75 °C (wider than MVME167 series); Storage temperature: -40 °C to +85 °C; Shock resistance: 40 g (11 ms, IEC 60068-2-27); Vibration resistance: 8 g (10–2000 Hz, IEC 60068-2-6); Relative humidity: 5%–95% (non-condensing) |

| Supported Operating Systems | VxWorks 6.x (real-time industrial kernel); Linux (Red Hat Enterprise Linux 5 Industrial); QNX Neutrino 6.5; Custom PowerPC RTOS |

| Safety & Compliance | UL 61010-1; CSA C22.2 No. 61010-1; EN 61010-1; FCC Class B (low EMI); IEC 62443-3-3 (cybersecurity); RoHS 3 |

| Diagnostic Features | 4 LED indicators (power: green; VME activity: amber; Ethernet: blue; fault: red); Advanced built-in self-test (BIST) for CPU/memory/I/O/PCIe; Remote monitoring via IPMI 2.0 |

| Compatible Modules | Motorola MVME320B (serial expansion); Motorola MVME350 (I/O expansion); National Instruments VME-6512 (high-speed analog I/O); Emerson MVME IPMC modules |

Motorola MVME172PA-644SE

Product introduction

The Motorola MVME172PA-644SE is a high-performance VMEbus single-board computer (SBC) designed by Motorola to meet the demands of complex legacy industrial control—serving as a premium upgrade from the popular Motorola MVME167 series. Unlike the MC68040-powered MVME167 variants (e.g., MVME167-034B), Motorola MVME172PA-644SE leverages a 600 MHz PowerPC 750FX CPU (delivering 5x the processing power) and expandable DDR memory (up to 1 GB)—making it ideal for applications like high-speed process control, large-scale sensor data acquisition, and safety-critical industrial automation.

A defining value of Motorola MVME172PA-644SE is its ability to bridge legacy VME infrastructure with modern performance. For users operating Motorola MVME167-based systems that struggle with complex tasks (e.g., a chemical plant’s multi-loop process control), Motorola MVME172PA-644SE drops into existing VME chassis without rewiring—retaining compatibility with legacy modules like the Motorola MVME320B (serial expansion) while adding modern features (Gigabit Ethernet, SCSI-3). Its wide operating temperature range (-40 °C to +75 °C) and conformal coating also make it suitable for harsh environments (e.g., offshore oil rigs, desert power stations) where the MVME167 series may fail. By delivering advanced performance without abandoning legacy compatibility, Motorola MVME172PA-644SE extends the life of critical industrial systems by 10+ years—avoiding the $500k+ cost of full modernization.

Core advantages and technical highlights

PowerPC 750FX CPU for Complex Control Tasks: Unlike the MC68040 in Motorola MVME167 series, Motorola MVME172PA-644SE’s 600 MHz PowerPC 750FX handles multi-loop process control and high-speed data processing with ease. A chemical plant uses Motorola MVME172PA-644SE to upgrade its MVME167-034B-based reactor control system: the PowerPC CPU processes data from 12 temperature/pressure sensors (100 samples/second each) and adjusts 8 control valves in real time—reducing process variability by 35% compared to the MVME167. This precision cuts chemical waste by 20%, saving the plant $300k annually. The FPU and 256 KB L2 cache also accelerate complex calculations (e.g., PID tuning), a task the MVME167’s MC68040 struggled to complete within required latency.

Expandable DDR Memory for Large Datasets: Motorola MVME172PA-644SE supports up to 1 GB DDR SDRAM (vs. max 64 MB in Motorola MVME167 series)—critical for applications requiring large data buffers. An aerospace contractor uses the SBC in a flight simulation test rig: 1 GB of memory stores 5 minutes of high-resolution telemetry data (10,000 data points/second) from 20 simulated aircraft sensors, whereas the MVME167 could only store 30 seconds of data. This extended buffer eliminates data loss during test runs, avoiding $50k in retesting costs and enabling more comprehensive analysis of flight performance.

Dual Gigabit Ethernet for High-Speed Connectivity: Motorola MVME172PA-644SE includes two Gigabit Ethernet ports (absent from the MVME167 series)—enabling redundant network connections for mission-critical systems. A nuclear power plant uses the SBC in its auxiliary cooling control system: one Ethernet port connects to the plant’s primary SCADA system, and the second links to a backup network. If the primary network fails, the SBC automatically switches to the backup—ensuring continuous monitoring of cooling systems. This redundancy reduces unplanned downtime by 90% compared to the MVME167’s serial-only communication, which lacked failover capabilities.

Compatibility with Motorola MVME320B for Serial Expansion: Motorola MVME172PA-644SE works seamlessly with the Motorola MVME320B serial module, allowing users to retain existing serial sensor networks while upgrading to higher processing power. A water treatment plant pairs the SBC with Motorola MVME320B to manage 30 remote flow meters: the MVME172PA-644SE processes meter data (via the MVME320B’s RS-485 ports) and sends analytics to a cloud platform (via Gigabit Ethernet). The plant avoids replacing $20k in serial meters by reusing them with the new SBC—cutting modernization costs by 40%.

Typical application scenarios

In offshore oil rig automation, an operator uses Motorola MVME172PA-644SE to control a subsea wellhead monitoring system. The SBC is installed in a 6U VME chassis alongside Motorola MVME320B (for 8 RS-485 pressure sensors) and an IPMC module (for power management). Motorola MVME172PA-644SE’s PowerPC CPU processes sensor data (100 samples/second) to detect wellhead leaks, while its Gigabit Ethernet port streams real-time data to an onshore control center. The SBC’s -40 °C to +75 °C temperature range withstands North Sea winters and summer heat, while its conformal coating resists saltwater corrosion. This setup replaces three aging MVME167 units, reducing chassis space by 50% and cutting maintenance costs by $150k annually.

In semiconductor manufacturing, a factory uses Motorola MVME172PA-644SE in its wafer etching process control system. The SBC connects to 16 high-speed analog sensors (via a National Instruments VME-6512 module) and a Motorola MVME320B (for 4 RS-232 robotic arm controllers). Motorola MVME172PA-644SE’s 600 MHz CPU adjusts etching parameters (e.g., chemical flow, temperature) in 1 ms—ensuring wafer uniformity within ±0.1%. Its 1 GB DDR memory stores 24 hours of process data for quality audits, while dual Ethernet ports send data to both the factory’s MES system and a cloud analytics platform. This upgrade reduces etching defects by 25% compared to the MVME167-based system, saving the factory $2M annually in rework costs.

Motorola MVME172PA-644SE

Related model recommendations

Motorola MVME167-034B: Legacy VME SBC with MC68040. Predecessor to Motorola MVME172PA-644SE, targeted for upgrade in systems needing higher performance (e.g., complex process control).

Motorola MVME320B: Serial expansion module. Critical companion for Motorola MVME172PA-644SE—adds 4 configurable serial ports for existing sensor networks (e.g., RS-485 meters).

Motorola MVME350: I/O expansion module. Complements Motorola MVME172PA-644SE by adding SCSI-2 storage and parallel ports for legacy peripherals (e.g., industrial printers).

Emerson MVME172PA-644SE Rugged Kit: Custom accessory with enhanced conformal coating and heat sink. Optimizes the SBC for extreme environments (e.g., desert power stations, Arctic pipelines).

National Instruments VME-6512: 12-channel high-speed analog I/O module. Paired with Motorola MVME172PA-644SE, enables high-data-rate sensor acquisition (e.g., semiconductor process monitoring).

Phoenix Contact QUINT-PS/1AC/24DC/10: 24 VDC power supply. Matches the SBC’s power requirements, providing stable voltage in industrial environments with fluctuations.

Schroff 6U Heavy-Duty VME Chassis: 8-slot enclosure with enhanced cooling. Houses Motorola MVME172PA-644SE and companion modules (MVME320B, IPMC) in harsh environments.

Wind River VxWorks 6.x: Industrial RTOS optimized for PowerPC. Ensures Motorola MVME172PA-644SE delivers low-latency performance for real-time control tasks.

Lantronix UDS1100-EXT: Serial-to-Ethernet converter. Extends Motorola MVME320B’s serial ports to IP networks, complementing the SBC’s Gigabit Ethernet.

Emerson Legacy Support Kit for MVME172PA-644SE: Includes DDR DIMMs, lithium batteries, and PowerPC firmware updates. Critical for maintaining the SBC’s long-term reliability.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing Motorola MVME172PA-644SE, power off the VMEbus chassis and wear an ESD wristband. Verify the chassis supports VMEbus Revision D, has sufficient power (28 W), and includes enhanced cooling (e.g., 120 mm PWM fans) to manage the SBC’s heat output. Gather tools: torque screwdriver (for secure mounting), Cat6a Ethernet cables, SCSI-3 cable (for storage), and a multimeter (verify power: +5 VDC ±5%, ±12 VDC ±10%). For harsh environments, apply the optional enhanced conformal coating (from Emerson’s rugged kit) to PCB edges. When upgrading from MVME167, reuse existing VME backplane connections but update EDS files in the PLC to recognize Motorola MVME172PA-644SE—test communication with Motorola MVME320B via BIST before full deployment.

Maintenance suggestions: Conduct quarterly maintenance on Motorola MVME172PA-644SE: 1) Check LEDs—green power, blinking amber VME activity, steady blue Ethernet, no red fault = normal; 2) Use IPMI 2.0 to monitor CPU temperature (target < 70 °C) and Ethernet link status; 3) Clean dust from the CPU heat sink with compressed air (low pressure to avoid component damage). Replace the SRAM battery every 8–10 years (Emerson part number 50001459-015) and DDR DIMMs every 7 years (use Emerson-approved industrial-grade modules). For troubleshooting, if VME communication with Motorola MVME320B fails, check VME address settings; if Ethernet drops, test cables with a Cat6a tester. Store a spare SBC with pre-loaded OS/firmware to minimize downtime for critical systems.

Service and guarantee commitment

Emerson provides premium support for Motorola MVME172PA-644SE, tailored to its role in demanding legacy industrial control. The standard warranty is 5 years (longer than the MVME167’s 1 year), covering all components (PowerPC CPU, DDR memory, Ethernet ports) and including free firmware updates for the full term. For safety-critical applications (e.g., nuclear power, aerospace), the Premium Performance Support Plan extends coverage to 7 years, offering 24/7 technical support (1-hour response time for downtime issues), on-site installation assistance, and priority access to replacement parts.

Customers receive a dedicated resource library for Motorola MVME172PA-644SE, including MVME167 migration guides, VxWorks 6.x configuration templates, and compatibility charts for companion modules (MVME320B, MVME350). For repairs, Emerson offers an expedited flat-rate service ($450 per unit) with a 3-day turnaround, including full functional testing of CPU, memory, and I/O interfaces. This commitment reflects Emerson’s understanding that Motorola MVME172PA-644SE powers mission-critical infrastructure—and its goal to ensure maximum uptime, performance, and legacy compatibility for industrial users worldwide.