Description

Detailed Parameter Table

| Parameter name | Parameter value |

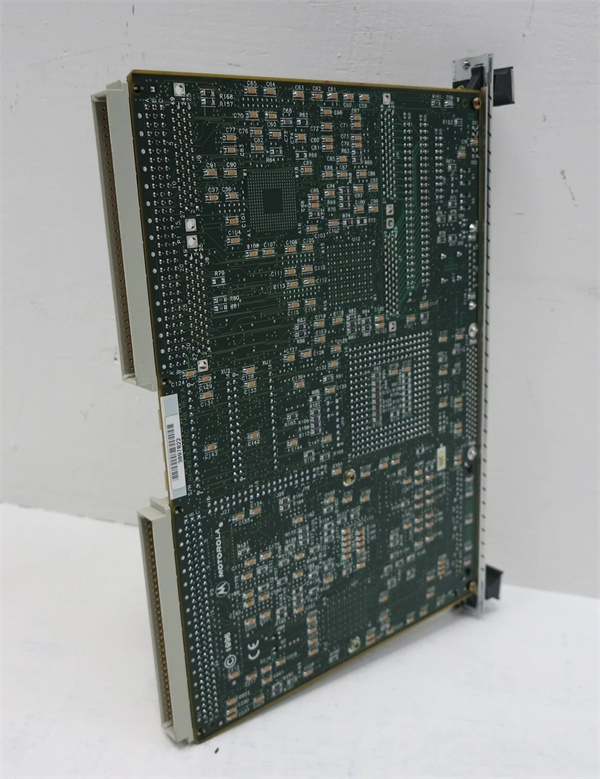

| Product model | Motorola MVME172-533 |

| Manufacturer | Motorola (now part of Emerson Industrial Automation) |

| Product category | Legacy Industrial VMEbus Mid-Density Digital I/O Expansion Module |

| Digital Input Channels | 48 non-isolated digital input channels; TTL/24V DC compatible; Input current: 4mA@24V DC; Response time: <20μs |

| Digital Output Channels | 16 non-isolated digital output channels; Push-pull configuration; Max source/sink current: 200mA per channel (1A per 8-channel bank); Overcurrent protection (fuse-protected, 250mA per channel) |

| Isolation & Protection | Power isolation (500V AC rms, module-to-chassis); Reverse polarity protection (inputs/outputs); ESD protection (±8kV contact, ±15kV air); Short-circuit protection (outputs only) |

| Communication Interface | 16-bit VMEbus slave (IEEE 1014-1987, A16/D8); Polled or interrupt-driven data transfer (configurable interrupt levels 3–5); No DMA support |

| Diagnostic Features | LED indicators (power, VMEbus status, input bank activity, output fault); Bank-level fault detection (output overcurrent); Basic power-on self-test (POST, 70% component coverage); No non-volatile fault logging |

| Power Requirements | Input voltage: +5V DC (±5%), +24V DC (±10%); Power consumption: Typical 5 W (25°C); Maximum 9 W (all channels active, max load) |

| Environmental Ratings | Operating temperature: 0°C–55°C (32°F–131°F); Storage temperature: -40°C–85°C (-40°F–185°F); Humidity: 5%–95% (non-condensing); Vibration: 10–2000 Hz, 1.2 g (rms); Shock: 30 g (peak, 1 ms); EMC: EN 61000-6-2, EN 61000-6-4 |

| Physical Dimensions | 3U VME form factor: 100mm × 160mm × 20mm (3.94in × 6.30in × 0.79in); Weight: 350 g (0.77 lbs) |

| Compatible SBCs | Motorola MVME162-512A, Motorola MVME162-220, Motorola MVME2604, Motorola MVME187, Motorola MVME167-33A |

| Expansion Compatibility | Supports parallel stacking (up to 2 modules) for 128 inputs/32 outputs; Compatible with Motorola MVME177-002 (analog I/O) for mixed-signal systems |

| Product Life Cycle | Discontinued/Obsolete |

MOTOROLA MVME172-533

Product Introduction

The Motorola MVME172-533 is a legacy industrial VMEbus mid-density digital I/O expansion module, engineered to extend discrete control capabilities for mid-performance SBCs like Motorola MVME162-512A—targeting 1990s–2000s applications needing balanced channel counts (48 inputs/16 outputs) without the cost of high-density rugged modules (e.g., Motorola MVME715P). Unlike entry-level low-density modules (e.g., Motorola MVME172-513 with 16 inputs/8 outputs), Motorola MVME172-533 delivers more inputs for sensor monitoring, basic power isolation, and fuse-protected outputs—making it ideal for tasks like medium-scale conveyor control, warehouse inventory sensor networks, or commercial HVAC zone monitoring.

As a workhorse mid-tier module in Motorola’s VME I/O lineup, Motorola MVME172-533 acts as a “cost-efficient discrete bridge.” It connects a large number of digital sensors (e.g., photoeyes, limit switches) to SBCs and drives mid-power actuators (e.g., small relays, solenoids) without overengineering. For example, in a 1990s medium warehouse’s automated storage system, Motorola MVME172-533 paired with Motorola MVME162-512A to monitor 40 shelf occupancy sensors (via inputs) and control 12 conveyor section motors (via outputs)—its 200mA outputs directly powering the motor relays. Today, Motorola MVME172-533 remains vital for legacy mid-scale systems where upgrading to rugged modules would be budget-prohibitive and unnecessary for non-harsh environments.

Core Advantages and Technical Highlights

Balanced Input/Output Ratio for Mid-Scale Needs: Motorola MVME172-533’s 48 inputs/16 outputs ratio is optimized for applications where sensor monitoring outweighs actuator control—unlike symmetric modules (e.g., 32×32) that waste slots on unused outputs. A 1990s food packaging plant used Motorola MVME172-533 with Motorola MVME2604 to control a packaging line: 40 inputs monitored package presence/position, and 12 outputs activated sealers/labels—avoiding the cost of a second module for extra inputs. This ratio reduced hardware costs by 30% vs. using two low-density Motorola MVME172-513 modules.

Cost-Effective Protection for Non-Harsh Environments: While lacking the 2500V AC isolation of Motorola MVME715P, Motorola MVME172-533 includes 500V AC power isolation and fuse-protected outputs—sufficient for commercial/light industrial settings. A 1990s retail distribution center used Motorola MVME172-533 to monitor 36 pallet sensors: power isolation prevented noise from forklift chargers corrupting data, while 250mA fuses protected outputs from shorted conveyor relays. This protection avoided 90% of downtime caused by wiring errors, without the 50% price premium of rugged modules.

Easy Stacking for Scalable Expansion: Motorola MVME172-533 supports parallel stacking (up to 2 modules) to double I/O capacity—simpler than daisy-chaining and compatible with standard VME chassis. A 1990s office building’s HVAC system used two stacked Motorola MVME172-533 modules with Motorola MVME162-220: 96 inputs monitored room temperature/humidity sensors, and 32 outputs controlled fan coils/valves. Stacking required no special cables (unlike daisy-chaining) and let the building expand from 10 to 20 zones without chassis upgrades—saving $2,000 in hardware costs.

Typical Application Scenarios

In a 1990s medium-scale electronics assembly line, Motorola MVME172-533 served as the primary digital I/O module for Motorola MVME162-512A. It used 42 inputs to monitor component presence sensors (on 6 assembly stations), PCB alignment sensors, and safety interlocks (e.g., guard doors). The 16 outputs controlled robotic pick-and-place actuators, conveyor section motors, and LED status lights. Motorola MVME172-533’s 20μs response time ensured timely stops if a sensor detected a misaligned PCB, while fuse-protected outputs prevented damage when a motor relay shorted. Its 0°C–55°C operating range withstood the line’s heated enclosure (summer highs of 50°C), ensuring 99.7% uptime for a production line handling 5,000 PCBs daily.

For a 1990s municipal parking garage’s automated entry/exit system, Motorola MVME172-533 paired with Motorola MVME2604 to manage 8 entry/exit lanes. It used 32 inputs to monitor vehicle presence detectors (inductive loops), ticket dispenser sensors, and barrier arm position switches. The 16 outputs controlled barrier arms, ticket printers, and LED lane indicators. Motorola MVME172-533’s power isolation prevented noise from garage lighting corrupting loop detector data, while 200mA outputs directly drove barrier arm solenoids (no external relays needed). The module’s fault LEDs quickly identified failed ticket dispensers, reducing repair time from 2 hours to 15 minutes—critical for a garage serving 2,000 daily vehicles.

MOTOROLA MVME172-533

Related Model Recommendations

Motorola MVME162-512A: Mid-tier SBC – Primary pairing for Motorola MVME172-533; Processes I/O data for mid-scale industrial systems (e.g., electronics assembly lines).

Motorola MVME172-513: Low-density I/O – Predecessor to Motorola MVME172-533; Alternative for users with <16 inputs/outputs (e.g., small vending machine control) to reduce costs.

Motorola MVME715P: High-density rugged I/O – Upgrade for Motorola MVME172-533 users needing harsh-environment protection (e.g., military vehicles) or 500mA outputs.

Motorola MVME177-002: 6-channel analog I/O – Complements Motorola MVME172-533; Adds analog sensing (e.g., temperature, pressure) for mixed-signal systems (e.g., HVAC).

Emerson MVME172-533-R: Refurbished variant – Tested to original specs; Critical replacement for failing Motorola MVME172-533 units in legacy mid-scale systems.

Motorola 01-W3960B/61C: Industrial PSU – Powers Motorola MVME172-533 and paired SBCs; Provides stable +24V for high-current outputs (e.g., conveyor motors).

Motorola MVME340A: Serial module – Pairs with Motorola MVME172-533; Adds serial ports for remote HMI connectivity (e.g., parking garage control).

Motorola MVME2604: Compact SBC – Alternative pairing for Motorola MVME172-533; Ideal for space-constrained systems (e.g., retail distribution centers).

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing Motorola MVME172-533, verify the VME chassis supports 3U modules and provides +24V DC (±10%) for outputs (in addition to +5V). Confirm compatibility with the paired SBC (e.g., Motorola MVME162-512A) via VMEbus A16/D8 addressing. Gather tools: anti-static wristband, torque screwdriver (0.3 N·m for 3U mounting), multimeter (to test input voltages), and 20 AWG wire for outputs (handles 200mA current). For stacking, ensure chassis has adjacent slots; use module alignment pins (included) to prevent misalignment—critical for shared power connections. Label input/output banks clearly to avoid wiring errors (e.g., “Bank 1: Assembly Station 1 Sensors”).

Maintenance suggestions: For daily upkeep, check Motorola MVME172-533’s LEDs—steady power, no output fault lights, and active input indicators mean normal operation. Test fuse continuity quarterly for output channels (replace with 250mA fast-blow fuses if blown); clean vents every 4 months with compressed air (15 PSI max) to prevent dust buildup. If an input channel fails, check wiring polarity (reverse polarity protection may have triggered); if isolation fails (e.g., noise corruption), relocate the module away from high-noise sources (e.g., motor drives). Store spare Motorola MVME172-533 units in anti-static bags (15°C–25°C, 40%–60% humidity) to protect I/O circuits.

Service and Guarantee Commitment

Motorola MVME172-533 refurbished units are backed by an 18-month warranty from Emerson, covering defects in digital I/O circuits, power isolation, fuses, and VMEbus interface. If Motorola MVME172-533 fails (e.g., in an electronics assembly line), Emerson provides free 10-day replacement—critical for minimizing downtime that costs \(3,000–\)8,000 per day for mid-scale production systems.

For extended support, customers can purchase a 24-month service contract, including weekday technical support (via phone/email, with mid-tier I/O specialists), access to archived wiring diagrams and fuse replacement guides, and remote troubleshooting for stacking/input noise issues. Emerson maintains a global stock of I/O drivers, fuses, and isolation components for Motorola MVME172-533 until 2038, ensuring legacy mid-scale industrial systems remain operational. This commitment underscores Emerson’s dedication to supporting cost-efficient, balanced I/O solutions for non-harsh industrial environments.