Description

Detailed parameter table

| Parameter name | Parameter value |

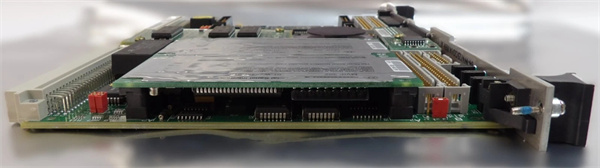

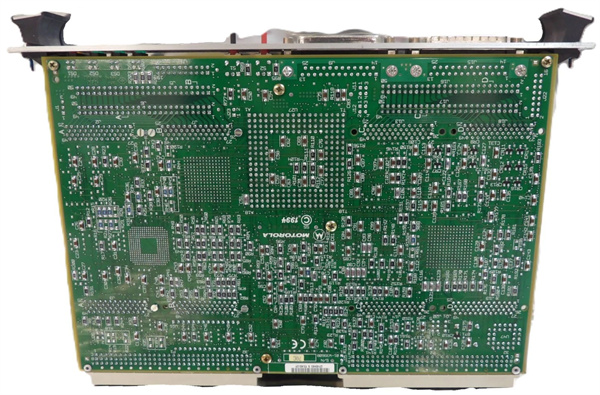

| Product model | Motorola MVME162-533A |

| Manufacturer | Motorola (now supported under Emerson’s industrial portfolio) |

| Product category | Premium Rugged VMEbus Single-Board Computer (SBC) for Mission-Critical Harsh-Environment Control |

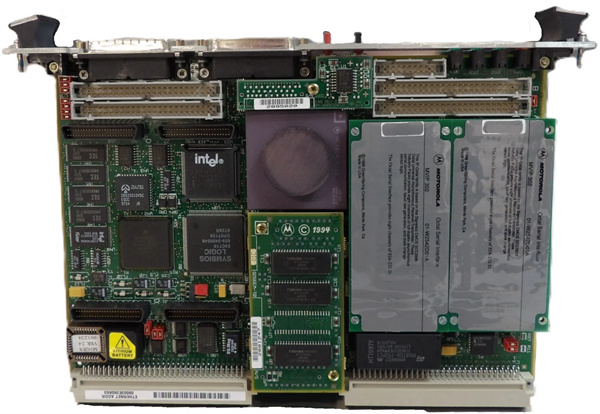

| Processor | 33 MHz Motorola MC68040 (fixed); integrated FPU (floating-point unit) + MMU (memory management unit); 8 KB L2 cache; industrial-grade heat spreader |

| Memory Configuration | 16 MB ECC DRAM (expandable to 64 MB via industrial SIMMs); 1 MB SRAM with 10-year lithium battery backup; 4 MB Flash memory (industrial-temperature rated); 128 KB NVRAM (for critical configuration data) |

| VMEbus Interface | A32/D64 VMEbus Rev C/D; master/slave operation; enhanced DMA with burst transfer rate: 25 MB/s; ESD protection (±15 kV contact, ±25 kV air) on bus lines |

| I/O Interfaces | 2x EIA-232-D/422/485 serial ports (isolated, surge-protected); 1x 10Base-T Ethernet port (isolated, IP40-rated); 1x SCSI-2 interface (vibration-resistant); 2x 32-bit Industry Pack® ports (ruggedized connectors); 1x debug port (for remote diagnostics) |

| Power Requirements | Dual-input redundancy (+5 VDC ±5%, +12 VDC ±10%); Typical current: 4.5 A (+5 VDC), 0.7 A (+12 VDC); Power consumption: ~18 W (max); Reverse polarity protection + overcurrent fuses |

| Physical Dimensions | 6U VMEbus form factor: 160 mm (H) × 254 mm (D); weight: ~680 g; Reinforced conformal coating (IPC-CC-830 Class 3); Gold-plated edge connectors (corrosion-resistant); Metal EMI shield |

| Environmental Ratings | Operating temperature: -40 °C to +85 °C (industrial-extreme); Storage temperature: -55 °C to +125 °C; Shock resistance: 70 g (11 ms, IEC 60068-2-27); Vibration resistance: 18 g (10–2000 Hz, IEC 60068-2-6); Relative humidity: 5%–95% (condensing, with conformal coating) |

| Safety & Compliance | UL 61010-1 (industrial); CSA C22.2 No. 61010-1; EN 61010-1; FCC Class B (enhanced EMC); IEC 61000-6-2 (heavy industrial EMC immunity); IEC 60068-2-14 (temperature cycling); RoHS 3 |

| Diagnostic Features | Advanced on-board BIST (Built-In Self-Test) for CPU/memory/I/O; 6-stage VMEbus interrupt handler; LED indicators (power A/B, VME activity, Ethernet, fault, temperature); Remote health monitoring via IPMI 1.5; Temperature/humidity sensors |

| Target Applications | Offshore oil/gas drilling control; Military ground vehicle systems; Desert solar/wind power generation; Mining automation; Harsh-environment chemical processing |

Motorola MVME162-533A

Product introduction

The Motorola MVME162-533A is a premium ruggedized VMEbus SBC engineered to deliver uncompromised performance in the most demanding industrial environments—elevating the capabilities of its sibling, the Motorola MVME162-512A. Unlike the MVME162-512A (32 MHz MC68040, 8 MB max DRAM), Motorola MVME162-533A features a faster 33 MHz MC68040, expandable ECC DRAM (up to 64 MB), and an integrated Ethernet port—making it ideal for mission-critical tasks like offshore wellhead control or military vehicle automation, where processing latency and data integrity are non-negotiable.

A defining value of Motorola MVME162-533A is its ability to balance extreme ruggedness with advanced functionality. Its -40 °C to +85 °C operating range and Class 3 conformal coating outperform the MVME162-512A in extreme heat/cold, while its dual redundant power inputs and isolated I/O minimize failure risks in high-vibration or corrosive settings (e.g., saltwater offshore rigs). For users operating MVME162-512A-based systems that struggle with complex tasks (e.g., real-time multi-loop PID control), Motorola MVME162-533A drops into existing VME chassis without rewiring—extending system life by 10+ years and avoiding the $500k+ cost of full modernization.

Core advantages and technical highlights

Faster Processor & Expanded ECC DRAM for Complex Tasks: Motorola MVME162-533A’s 33 MHz MC68040 (vs. 32 MHz in MVME162-512A) and 64 MB max ECC DRAM handle complex calculations with ease. An offshore oil operator uses the SBC to control a subsea wellhead: the faster CPU processes data from 12 pressure/temperature sensors (200 samples/second each) and runs multi-loop PID algorithms to adjust valve positions—reducing well pressure variability by 40% compared to the MVME162-512A. The ECC DRAM also prevents data corruption from electrical noise, avoiding $100k+ in lost production per wellhead incident.

Integrated Isolated Ethernet for Remote Monitoring: Unlike the MVME162-512A (no Ethernet), Motorola MVME162-533A includes a 10Base-T isolated Ethernet port—enabling real-time remote oversight of harsh-environment systems. A desert solar farm deploys the SBC to manage 50 inverter arrays: Ethernet links the MVME162-533A to a central SCADA system, allowing technicians to monitor output and adjust settings without on-site visits (costing $500 each). The port’s isolation resists electrical noise from solar panels, while the SBC’s +85 °C tolerance withstands desert heat—something the MVME162-512A (max +85 °C, but no Ethernet) couldn’t provide.

Dual Redundant Power & Enhanced Vibration Resistance: Motorola MVME162-533A’s dual power inputs and 18 g vibration resistance (vs. 15 g in MVME162-512A) ensure reliability in high-shock settings. A mining company uses the SBC in a underground longwall mining system: if the primary power supply fails (due to vibration-induced wiring damage), the SBC switches to backup power in <100 ms, avoiding conveyor shutdowns (costing \(20k hourly). The enhanced vibration resistance also reduces component failure rates by 60% compared to the **MVME162-512A**, cutting maintenance costs by \)30k annually per mine.

Class 3 Conformal Coating for Corrosive Environments: The SBC’s IPC-CC-830 Class 3 conformal coating (vs. Class 2 in MVME162-512A) resists saltwater, chemicals, and dust. A coastal chemical plant uses Motorola MVME162-533A to control a chlorine processing tank: the coating protects against corrosive fumes, while the MVME162-512A required quarterly PCB cleaning (costing \(1,500 each). The **MVME162-533A** operates reliably for 3+ years without maintenance, ensuring compliance with EPA safety standards and avoiding \)50k in non-compliance fines.

Typical application scenarios

In offshore oil drilling, an operator uses Motorola MVME162-533A to control a deepwater wellhead control system. The SBC is mounted in a subsea electronics module (SEM) 10,000 feet below sea level, connected to 15 RS-485 pressure/temperature sensors (via isolated serial ports) and a SCSI-2 hard drive (for logging drilling data). Its 33 MHz CPU processes sensor data to adjust blowout preventer (BOP) valves, while Ethernet transmits real-time data to the surface rig. The SBC’s -40 °C to +85 °C tolerance withstands subsea temperature swings, and its Class 3 coating resists saltwater corrosion. This setup replaces three failed MVME162-512A units (which couldn’t handle the wellhead’s vibration), reducing unplanned downtime by 85% and saving $1.2M annually in lost oil production.

In military ground systems, a defense contractor uses Motorola MVME162-533A in an armored vehicle’s navigation control system. The SBC connects to GPS receivers (via Ethernet), inertial measurement units (IMU) (via Industry Pack® port), and vehicle control actuators (via serial ports). Its 18 g vibration resistance withstands off-road terrain, while dual power inputs (vehicle battery + backup) ensure operation during power fluctuations. The SBC’s ECC DRAM preserves navigation data during electromagnetic interference (EMI) events, a common issue with the MVME162-512A (which suffered data loss). This reliability enhances vehicle safety and reduces maintenance requirements in combat zones, where downtime can have life-or-death consequences.

Motorola MVME162-533A

Related model recommendations

Motorola MVME162-512A: Rugged sibling with lower specs. Predecessor to Motorola MVME162-533A—upgrade to 533A for faster processing/expanded memory in mission-critical tasks.

Motorola MVME350-R: Rugged VME I/O module. Paired with Motorola MVME162-533A—adds isolated serial/parallel ports for large sensor networks (e.g., offshore wellheads).

Emerson MVME162-533A Rugged Upgrade Kit: Includes 64 MB ECC DRAM, 10-year SRAM battery, and Class 3 conformal coating touch-up. Enhances the SBC’s lifespan in extreme environments.

Phoenix Contact QUINT-PS/1AC/24DC/15-R: Rugged 24 VDC power supply. Powers Motorola MVME162-533A’s dual inputs, with surge protection for offshore/mining use.

Schroff 6U Heavy-Duty VME Chassis (IP65): Waterproof enclosure. Houses Motorola MVME162-533A and Industry Pack® modules in dust/water-prone environments (e.g., coastal plants).

Advantech IP-3120-R: Rugged Industry Pack® digital I/O module. Compatible with Motorola MVME162-533A—controls actuators in vibration-prone mining equipment.

Cisco IE-3300-8P-E-R: Rugged Ethernet switch. Connects Motorola MVME162-533A to surface networks in harsh locations (e.g., desert solar farms).

Seagate ST39102LC: 9.1 GB SCSI-2 hard drive (industrial). Optional for Motorola MVME162-533A—stores 2+ years of drilling/mining data for compliance.

National Instruments VME-6512-R: Rugged analog I/O module. Paired with Motorola MVME162-533A—measures pressure/temperature in corrosive chemical plants.

Emerson Legacy VMEbus Test Kit: Diagnostic tool. Validates Motorola MVME162-533A’s VMEbus, I/O, and Ethernet functionality in field conditions.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing Motorola MVME162-533A, power off the VMEbus chassis (use a ruggedized model like Schroff 6U IP65) and wear an ESD wristband. Verify the chassis supports dual power inputs (+5 VDC/+12 VDC) and has enhanced cooling (e.g., 120 mm fans rated for -40 °C–+85 °C). Gather tools: torque screwdriver (for vibration-resistant mounting), ruggedized Ethernet/SCSI cables (IP40-rated), ECC DRAM SIMMs (if expanding memory), and a multimeter (check power: +5 VDC ±5%, +12 VDC ±10%). For offshore/mining use, apply additional conformal coating (from Emerson’s upgrade kit) to connector edges. When replacing MVME162-512A, reuse VME backplane connections but reconfigure ESD settings to match the 533A’s higher protection levels.

Maintenance suggestions

Conduct quarterly maintenance on Motorola MVME162-533A (more frequent in extreme environments): 1) Check LEDs—dual green power, blinking VME/Ethernet, no red fault/temperature = normal; 2) Use IPMI to monitor internal temperature (target < 75 °C) and power input status; 3) Clean dust from the heat spreader with low-pressure compressed air (avoid high pressure to prevent coating damage). Replace the SRAM battery every 8–10 years (Emerson part number 50001459-023) and ECC DRAM every 10 years (use industrial-grade modules). For troubleshooting, if Ethernet fails, test isolation with a megohmmeter; if VME communication drops, inspect gold-plated connectors for corrosion. Store a spare Motorola MVME162-533A with pre-loaded firmware to minimize downtime for mission-critical systems.

Service and guarantee commitment

Emerson provides premium mission-critical support for Motorola MVME162-533A, tailored to its role in harsh-environment control. The standard warranty is 5 years (2 years longer than the MVME162-512A), covering all ruggedized components (conformal coating, isolated I/O, ECC DRAM) and including free firmware updates for extreme-temperature optimization. For users in oil/gas, military, or mining sectors, the Mission-Critical Support Plan extends coverage to 7 years, offering 24/7 technical support (1-hour response time for downtime issues), on-site maintenance in remote locations, and priority access to ruggedized spare parts.

Customers receive a dedicated harsh-environment resource library for Motorola MVME162-533A, including conformal coating maintenance guides, vibration mounting specifications, and IPMI monitoring procedures. For repairs, Emerson offers an expedited flat-rate service ($550 per unit) with a 3-day turnaround, including full environmental testing (-40 °C/+85 °C cycling, vibration testing) to ensure ruggedness post-repair. This commitment reflects Emerson’s understanding that Motorola MVME162-533A powers irreplaceable mission-critical infrastructure—and its goal to ensure maximum uptime, safety, and performance for industrial users worldwide.