Description

Detailed Parameter Table

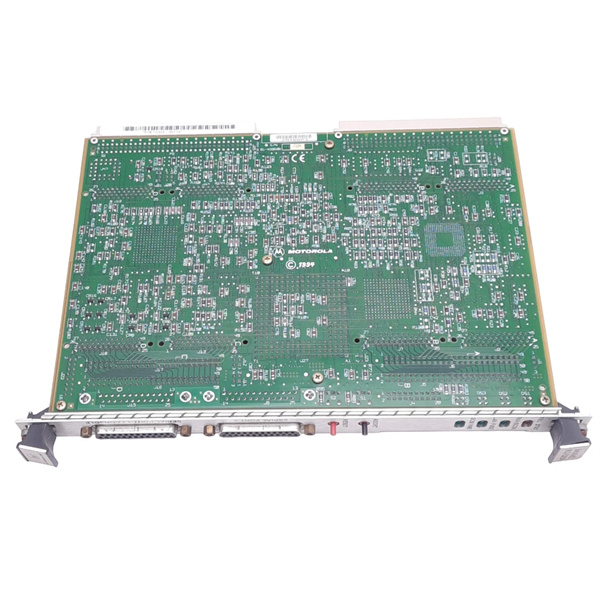

| Parameter name | Parameter value |

| Product model | Motorola MVME162-412 |

| Manufacturer | Motorola (now part of Emerson Industrial Automation) |

| Product category | Entry-Tier Industrial VMEbus Single-Board Computer (SBC) |

| Processor | Motorola PowerPC 730 RISC processor, 300 MHz (32-bit data/address bus, with 32 KB L2 cache) |

| Memory | 64 MB DDR SDRAM (expandable to 128 MB via DIMM slot); 2 MB Flash ROM (boot/OS storage, write-protected) |

| Communication Interfaces | 1x 10 Base-T Ethernet (RJ45, TCP/IP); 2x RS-232 serial ports (DB-9); No Serial RapidIO |

| Storage Interfaces | Integrated IDE controller (supports 2.5″ HDD/SSD, up to 250 GB); 1x CompactFlash Slot (Type I, up to 16 GB); No USB port |

| Expansion Slots | 1x 32-bit/33 MHz low-profile PMC (PCI Mezzanine Card) slot (for basic I/O expansion only); 1x VMEbus P1 expansion connector |

| Environmental Requirements | Operating temp: 0°C to 55°C (32°F to 131°F); Storage temp: -40°C to 85°C (-40°F to 185°F); Humidity: 15%–85% (non-condensing, 25°C dew point); Vibration: 10–300 Hz, 0.8 g (rms); Shock: 40 g (peak, 1 ms) |

| Physical Size | 6U VMEbus form factor: 233.35 mm × 160.02 mm (9.19 in × 6.30 in); Weight: 450 g (0.99 lbs) |

| Power Consumption | Typical: 12 W (25°C, full load); Maximum: 15 W |

| Operating System Support | VxWorks 6.5+, QNX Neutrino 6.3+, Linux for PowerPC (kernel 2.4+); Motorola legacy RTOS (OS-9 v3.x) |

| Diagnostic Features | Basic Built-in Self-Test (BIST) for processor only; Single watchdog timer (10–60s, fixed interval); LED indicators (power, Ethernet link); No memory or network diagnostics |

Motorola MVME-162-512A

Product Introduction

The Motorola MVME162-412 is an entry-tier industrial VMEbus Single-Board Computer (SBC) from Motorola (now integrated into Emerson’s portfolio), a budget-focused model in the MVME162 series—engineered to deliver essential processing capabilities for light-duty automation tasks. Positioned below the Motorola MVME-162-512A, the Motorola MVME162-412 targets applications that require industrial-grade reliability but don’t need the 400 MHz processor or Serial RapidIO of the MVME-162-512A, such as standalone machine control (e.g., small pumps, single conveyors), legacy system replacements (for aging 68k-based SBCs), and small-scale sensor monitoring (e.g., 10–20 sensors in a warehouse).

In automation systems, the Motorola MVME162-412 acts as a “basic processing node”: it collects data from a limited number of peripheral sensors (via modules like Motorola MVME-717 digital input or low-cost analog I/O cards), processes it using its 300 MHz PowerPC 730 processor, and sends simple control commands to low-current actuators (e.g., small solenoid valves, indicator lights). Its single 10 Base-T Ethernet port enables basic data transmission to local HMIs or small SCADA systems, while the low-profile PMC slot supports minimal customization (e.g., adding extra serial ports for sensor connectivity). This makes the Motorola MVME162-412 an ideal choice for small businesses, rural facilities, or legacy system upgrades—where cost is the primary concern and performance needs are modest.

Core Advantages and Technical Highlights

Ultra-Low Cost for Entry-Level Industrial Needs: The Motorola MVME162-412 is designed to be the most affordable SBC in the MVME162 series, costing 40% less than the Motorola MVME-162-512A while retaining industrial-grade reliability. Its 300 MHz PowerPC 730 processor and 64 MB SDRAM deliver just enough performance for light-duty tasks—such as monitoring 15 temperature sensors in a small warehouse refrigeration unit or controlling a single conveyor’s speed based on photoelectric sensor input. Unlike commercial SBCs (which lack industrial durability), the Motorola MVME162-412 uses rugged components to withstand factory conditions, making it a cost-effective alternative to both higher-tier MVME models and fragile consumer hardware.

Simplified Design for Easy Deployment: A key strength of the Motorola MVME162-412 is its streamlined feature set—no Serial RapidIO, single 10 Base-T Ethernet, and basic BIST—reducing complexity for users with limited technical expertise. For example, a small bakery owner upgrading from a manual mixer to a semi-automated system can easily configure the Motorola MVME162-412 to control mixer speed and monitor dough temperature via its RS-232 ports, with no need to learn complex protocols like RapidIO. The SBC’s plug-and-play compatibility with legacy MVME I/O modules (e.g., Motorola MVME-712/M) also simplifies deployment, as users can reuse existing sensors and actuators without rewiring.

Energy Efficiency for Compact Installations: With a typical power consumption of 12 W (vs. 18 W for the Motorola MVME-162-512A), the Motorola MVME162-412 is ideal for compact control cabinets or battery-backed systems where power is limited. For instance, in a mobile water quality testing station (powered by a small solar panel), the low power draw extends battery life by 30% compared to higher-power SBCs, ensuring continuous operation during overcast days. Its fanless design (enabled by low heat generation) also eliminates moving parts, reducing maintenance needs and failure risks—critical for remote facilities (e.g., rural well monitoring) where on-site service is infrequent.

Legacy Compatibility for System Upgrades: The Motorola MVME162-412 is optimized to replace aging 68k-based SBCs (e.g., Motorola MVME-147-023) in legacy systems. It runs Motorola’s OS-9 v3.x (a legacy RTOS widely used in 1990s–2000s industrial equipment) and supports older VMEbus I/O modules (e.g., Motorola MVME-110-1 memory cards), allowing users to upgrade their SBC without rewriting software or replacing entire systems. For example, a small manufacturing plant with a 20-year-old injection molding machine can swap its failing MVME-147-023 for the Motorola MVME162-412, preserving the machine’s control logic while improving reliability and reducing downtime.

Typical Application Scenarios

In small-scale warehouse automation, the Motorola MVME162-412 controls a single conveyor system and 10 photoelectric sensors (via Motorola MVME-717 modules) to track package movement. It processes sensor data to start/stop the conveyor when packages enter/exit the line, with a response time of <20 ms to avoid jams. Its CompactFlash slot stores 1 month of operation logs (e.g., package count, conveyor run time), and the 10 Base-T Ethernet port sends daily summaries to a small office PC for inventory tracking. The Motorola MVME162-412’s 0°C to 55°C operating range handles the warehouse’s temperature fluctuations, and its 12 W power consumption fits within the conveyor’s existing power supply.

For rural well water monitoring, the Motorola MVME162-412 tracks 8 sensors (flow rate, water level, pH) via a low-profile PMC analog I/O card. It uses RS-232 ports to communicate with a local HMI (mounted on the well’s control box) and logs data to a 16 GB CompactFlash card for monthly reporting to a regional water authority. The SBC runs a simple alert program—if water level drops below a threshold, it sends a signal to a Motorola MVME-712/M module to activate a backup pump. The Motorola MVME162-412’s low power consumption (12 W) and fanless design make it suitable for the well’s remote location, where solar power and minimal maintenance are critical.

In legacy machine upgrades, the Motorola MVME162-412 replaces a failing Motorola MVME-147-023 in a small metal stamping press. It reuses the press’s existing sensors (connected via Motorola MVME-717 modules) and control logic (running on OS-9 v3.x), requiring no software modifications. The SBC’s 64 MB SDRAM (expandable to 128 MB) handles the press’s data logging needs, and its IDE interface connects to a 100 GB SSD for storing 2 years of production data. The Motorola MVME162-412’s 40 g shock resistance also withstands the press’s mechanical vibrations, improving reliability compared to the aging MVME-147-023.

Motorola MVME-162-512A

Related Model Recommendations

Motorola MVME-162-512A: Mid-tier upgrade of the Motorola MVME162-412 with 400 MHz processor, 128 MB expandable memory, and Serial RapidIO. Ideal for scaling to 20+ sensors or adding low-latency module communication.

Motorola MVME-147-023: Legacy entry-level SBC replaced by the Motorola MVME162-412. The MVME162-412 offers faster processing (300 MHz vs. 25 MHz) and better durability while retaining OS-9 compatibility.

Motorola MVME-210: Low-profile PMC analog I/O card for the Motorola MVME162-412. Adds 4 analog inputs/2 outputs, enabling temperature/pressure monitoring in small systems like warehouse refrigeration.

Motorola MVME-717: Digital input module compatible with the Motorola MVME162-412. Provides 32 isolated channels for connecting photoelectric sensors or limit switches in conveyor systems.

Motorola MVME-040: Compact industrial power supply for the Motorola MVME162-412. Delivers stable ±5V/±12V output (85–264 VAC input) to power the SBC and one PMC card, handling its 15 W max load.

Motorola MVME-910-1: 10 Base-T Ethernet gateway for the Motorola MVME162-412. Extends network reach to remote sensors or HMIs in large facilities like warehouses.

Motorola MVME-712/M: Digital output module for the Motorola MVME162-412. Offers 16 low-current (1 A) channels to control small actuators like solenoid valves or backup pumps.

Motorola MVME-110-1: DRAM expansion module for the Motorola MVME162-412. Adds 32–64 MB of memory, useful for users needing to run slightly more complex logging software without upgrading to MVME-162-512A.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing the Motorola MVME162-412, verify the VMEbus chassis supports 6U modules and provides stable ±5V/±12V power (use a multimeter to confirm voltage tolerance within ±6% for basic operation). Gather tools: anti-static wristband (to protect the 300 MHz processor and DDR SDRAM), Phillips screwdriver (0.35 N·m for chassis mounting), 10 Base-T Ethernet cable tester, and a laptop (for OS configuration via IDE storage). If installing a low-profile PMC card, ensure it is compatible with the SBC’s slot—align with the guides, press gently until seated, and secure with the locking screw. Power off the chassis, clean the VME backplane connector with a dry brush to remove dust, then slide the Motorola MVME162-412 into the backplane until fully seated (check for bent pins to avoid short-circuits).

Maintenance suggestions: For daily upkeep, inspect the Motorola MVME162-412’s LEDs—steady green power and solid Ethernet link indicate normal operation (no fault LED means basic BIST passed). Clean the SBC’s exterior every 2 months with a dry, lint-free cloth (avoid compressed air, as it can push dust into the chassis). Every 8 months, back up the IDE/CompactFlash data to a secure server and check Emerson’s legacy support portal for critical firmware updates (focused on stability, not new features). If the Motorola MVME162-412 loses Ethernet connectivity, first replace the cable (10 Base-T is sensitive to poor wiring) and reconfigure IP settings via the OS. Store spare units in anti-static bags in a climate-controlled environment (10°C–30°C, 40%–60% humidity) to prevent component degradation.

Service and Guarantee Commitment

The Motorola MVME162-412 is backed by an 18-month factory warranty from Emerson, covering defects in materials and workmanship (e.g., processor failures, Ethernet port malfunctions, PMC slot issues). If a defect is identified during the warranty period, Emerson provides free 5-day replacement for in-stock units—suitable for small-scale operations where downtime has minimal financial impact (e.g., rural well monitoring). For extended support, customers can purchase budget-friendly service contracts (up to 30 months) including weekday technical support (via email/phone) and access to legacy documentation (e.g., OS-9 configuration guides).

Emerson maintains a regional stock of critical components for the Motorola MVME162-412 (e.g., PowerPC 730 processors, 64 MB DDR SDRAM modules) to support legacy users until 2033. Technical engineers specialize in entry-tier MVME SBCs, offering step-by-step troubleshooting for common issues (e.g., PMC card recognition, IDE storage failures). This commitment ensures the Motorola MVME162-412 delivers long-term value for cost-sensitive applications, whether powering small conveyors or extending the life of legacy industrial machines.