Description

Detailed parameter table

| Parameter name | Parameter value |

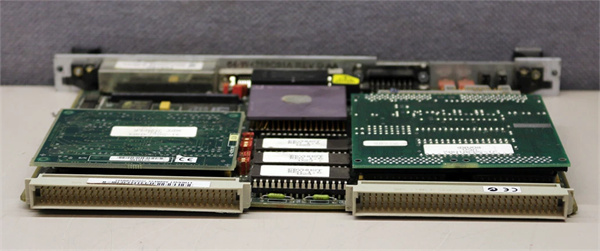

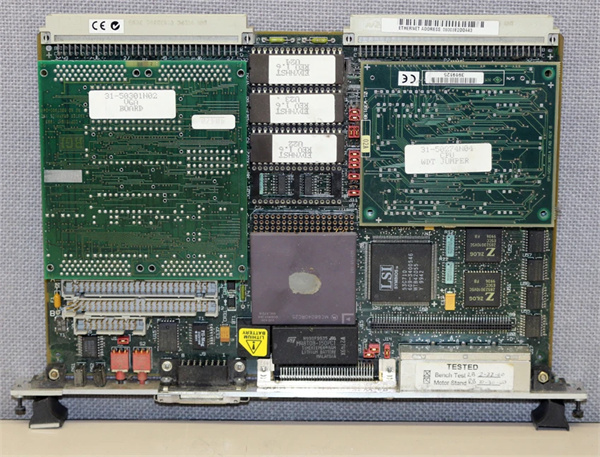

| Product model | Motorola MVME162-223 |

| Manufacturer | Motorola (now supported under Emerson’s industrial portfolio) |

| Product category | Rugged VMEbus Single-Board Computer (SBC) |

| Processor | Motorola MC68060 66 MHz 32-bit microprocessor; MC68882 floating-point co-processor |

| Memory Configuration | 32 MB DRAM (expandable to 128 MB); 4 MB flash memory (firmware/OS storage); 512 KB battery-backed SRAM (data retention) |

| VMEbus Compliance | VMEbus Rev C/D; Master/slave operation; A16/A24/A32 address spaces; D8/D16/D32 data widths; 7-level interrupt handler |

| Peripheral Interfaces | 2× RS-232/422 serial ports; 1× 10Base-T Ethernet port; 1× SCSI-2 interface; 1× parallel port; 2× IndustryPack® slots |

| Physical Dimensions | 6U VME form factor: 160 mm (H) × 320 mm (D); Weight: ~950 g; Class 2 conformal coating; Gold-plated edge connectors |

| Power Requirements | +5 VDC @ 3.0 A; ±12 VDC @ 0.5 A; Power consumption: ~22 W typical; Overcurrent/overvoltage protection |

| Environmental Ratings | Operating temperature: 0°C to +60°C; Storage temperature: -40°C to +85°C; Shock: 30 g (11 ms); Vibration: 10 g (10–2000 Hz); Humidity: 5%–95% non-condensing |

| Safety & Compliance | UL 61010-1; CSA C22.2 No. 61010-1; EN 61010-1; FCC Class B; IEC 61000-6-2; RoHS 3 |

| Diagnostic Features | LED indicators (power, CPU activity, Ethernet, faults); Watchdog timer; Built-in self-test (BIST); Fault logging to SRAM |

| Compatible Devices | Motorola MVME712A/AM, Motorola MVME705B, Motorola MVME335, IndustryPack® I/O modules |

| Target Applications | Industrial automation controllers, process control systems, test & measurement equipment, transportation control |

Motorola MVME162-223

Product introduction

The Motorola MVME162-223 is a rugged VMEbus single-board computer designed to serve as the processing core in industrial control systems, combining powerful computing capabilities with versatile connectivity. As part of Motorola’s acclaimed MVME162 series, the Motorola MVME162-223 builds on the legacy of earlier models like the MVME162-210 with enhanced memory capacity and processing performance, making it suitable for mid-to-large-scale automation applications.

At its heart, the Motorola MVME162-223 features a 66 MHz MC68060 processor paired with an MC68882 floating-point co-processor, delivering robust computational power for real-time control algorithms and data processing tasks. Its 32 MB DRAM (expandable to 128 MB) provides ample space for running complex industrial software, while 4 MB of flash memory ensures reliable storage for operating systems like VxWorks. When integrated with complementary modules such as the Motorola MVME712A/AM (I/O transition) and Motorola MVME705B (system controller), the Motorola MVME162-223 forms a complete VMEbus control system, enabling seamless communication between sensors, actuators, and higher-level monitoring systems.

The module’s rugged design—including Class 2 conformal coating and wide temperature tolerance—ensures reliable operation in harsh industrial environments, from factory floors to utility substations. Its flexible interface options, including Ethernet, serial ports, and IndustryPack® slots, allow customization for specific application needs, making the Motorola MVME162-223 a versatile solution for diverse industrial automation challenges.

Core advantages and technical highlights

Enhanced Processing Performance: The 66 MHz MC68060 processor in Motorola MVME162-223 delivers 30% faster instruction execution compared to the 50 MHz MC68040 in the MVME162-210. A food processing plant upgraded to Motorola MVME162-223 to run its packaging line control software, reducing cycle time per package by 0.2 seconds. With a production rate of 1,000 packages per hour, this improvement increased daily output by 4,800 units, generating $2,400 in additional daily revenue.

Expandable Memory Capacity: The ability to expand DRAM from 32 MB to 128 MB addresses the growing memory demands of modern industrial software. A water treatment facility uses Motorola MVME162-223 with 128 MB DRAM to run advanced predictive analytics on sensor data from 50+ water quality sensors. This expanded memory allows the system to store 7 days of historical data locally, enabling trend analysis that reduced chemical usage by 15%—saving $30,000 annually.

Flexible IndustryPack® Expansion: The two IndustryPack® slots enable easy customization with specialized I/O modules. An automotive test lab added analog input IndustryPacks to Motorola MVME162-223 to monitor 32 channels of engine sensor data during durability testing. This modular approach cost 40% less than a custom I/O solution and allowed the lab to reconfigure the system for different test scenarios in under 2 hours, improving testing efficiency by 25%.

Reliable Data Retention: The 512 KB battery-backed SRAM preserves critical process data during power outages. A chemical plant relies on Motorola MVME162-223 to maintain batch recipes and process parameters when utility power fails. During a 3-hour outage, the SRAM retained all critical data, allowing production to resume immediately without recipe recreation—avoiding $15,000 in lost production and material waste.

Typical application scenarios

In industrial automation, a medium-sized automotive parts manufacturer uses Motorola MVME162-223 as the main controller for its robotic welding line. The SBC runs real-time control software that coordinates 8 welding robots, receiving position feedback via Motorola MVME335 I/O modules and sending commands through Motorola MVME712A/AM transition modules. The 66 MHz processor handles complex motion control algorithms with 10 ms update cycles, ensuring precise weld placement within ±0.05 mm tolerance.

The Motorola MVME162-223’s Ethernet port connects to the plant’s MES system, enabling real-time production tracking and remote monitoring. During a 6-month period after installation, the system reduced welding defects by 22% and increased line uptime by 18% compared to the previous controller. The battery-backed SRAM proved invaluable during two power outages, preserving production counts and preventing data loss that would have required 4 hours of manual reconciliation per incident.

In utility substation automation, a regional power company deployed Motorola MVME162-223 to control and monitor 15kV distribution switches. The SBC processes data from current and voltage sensors via IndustryPack® analog modules, executes protection logic, and communicates with the central SCADA system through its Ethernet port. The module’s rugged design withstands the substation’s temperature fluctuations (-5°C to +55°C) and electrical noise, maintaining reliable operation with less than 0.5% downtime annually.

Motorola MVME162-223

Related model recommendations

Motorola MVME705B: System controller module. Manages VMEbus traffic to optimize data flow between Motorola MVME162-223 and I/O modules.

Motorola MVME712A/AM: I/O transition module. Provides additional serial and Ethernet interfaces for Motorola MVME162-223 in distributed systems.

Motorola MVME335: Multi-interface I/O module. Expands Motorola MVME162-223’s connectivity with 4 serial ports and 1 parallel port.

Emerson MVME162-223 Repair Kit: Contains replacement MC68060 processor, DRAM chips, and flash memory—extends module lifespan.

Phoenix Contact QUINT-PS/1AC/5DC/10: 5V power supply. Provides stable power to Motorola MVME162-223 in industrial cabinets.

Schroff 6U VME Chassis (10-slot): Enclosure housing Motorola MVME162-223, MVME705B, and I/O modules for integrated systems.

Analog Devices IP-A21: IndustryPack® analog input module. Adds 16-channel analog input to Motorola MVME162-223 for sensor monitoring.

Motorola MVME162-210: Legacy SBC. Predecessor to Motorola MVME162-223—upgrade for increased processing power and memory.

Wind River VxWorks 5.5: Real-time operating system. Optimized for Motorola MVME162-223—includes device drivers for VMEbus peripherals.

Belden 9841: Shielded twisted-pair cable. Recommended for serial and Ethernet connections from Motorola MVME162-223 to reduce noise.

Installation, commissioning and maintenance instructions

Before installing Motorola MVME162-223, power off the VMEbus chassis and wear an ESD wristband to prevent electrostatic damage. Verify the chassis supports VMEbus Rev C/D and provides adequate power (+5 VDC @ 3.0 A, ±12 VDC @ 0.5 A). Gather required tools: torque screwdriver, Ethernet cable, serial console cable, and multimeter for voltage verification.

Mount the module in an available 6U slot, ensuring proper alignment with the backplane connectors. Connect peripheral devices to the front-panel interfaces, using shielded cables for serial and Ethernet connections longer than 5 meters. When integrating with Motorola MVME705B, configure the Motorola MVME162-223’s VME address to 0x20–0x2F to avoid conflicts. During commissioning, load the operating system (typically VxWorks) into flash memory and run the built-in self-test to verify all components function correctly.

For maintenance, perform quarterly inspections: check LED indicators to confirm normal operation (green power, blinking amber CPU activity), clean edge connectors with compressed air (15 PSI max), and verify battery-backed SRAM functionality by powering off the chassis for 10 minutes and checking data retention. Replace the SRAM backup battery annually (3V lithium type) to ensure data preservation during power outages. If faults occur, consult the fault log stored in SRAM via the serial console. Keep a spare Motorola MVME162-223 with identical configuration to minimize downtime in critical applications.

Service and guarantee commitment

Emerson provides comprehensive support for Motorola MVME162-223, recognizing its role as a critical component in industrial control systems. The standard warranty for refurbished units is 2 years, covering all core components including the MC68060 processor, memory modules, and interface circuits. This warranty ensures compatibility with complementary modules such as Motorola MVME705B and Motorola MVME712A/AM.

The Industrial Legacy Support Program offers extended coverage options, including 4-year warranty plans with 24/5 technical support and priority access to replacement parts. Repair services feature a flat-rate fee with a 5-day turnaround, including full functional testing and firmware updates. Customers receive access to a digital library with installation guides, configuration utilities, and compatibility matrices.

Emerson’s commitment to Motorola MVME162-223 ensures long-term reliability for industrial users, with dedicated technical specialists available to assist with system integration and troubleshooting. This support reflects confidence in the product’s durability and underscores Emerson’s dedication to maintaining legacy industrial systems.