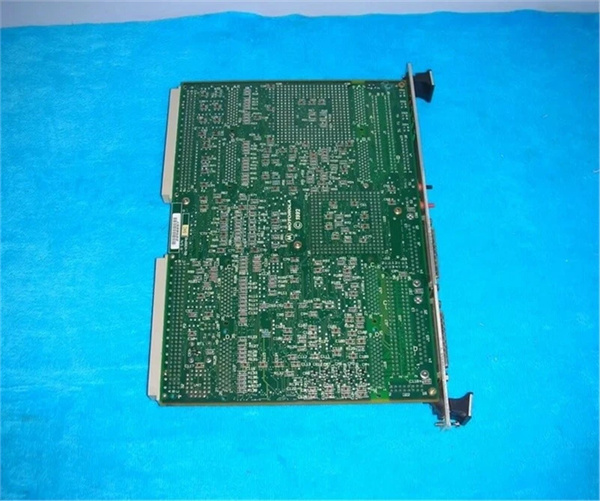

Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | Motorola MVME162-13 |

| Manufacturer | Motorola (now supported under Emerson’s industrial portfolio) |

| Product category | Enhanced Mid-Tier VMEbus Embedded Controller for Scaling Mid-Scale Industrial Systems |

| Processor | 25 MHz MC68LC040 32-bit microprocessor (fixed); 8 KB cache; integrated MMU; Optional 25 MHz MC68040 (adds FPU for complex calculations) |

| Memory | 4 MB shared DRAM (expandable to 16 MB via SIMM slot); 512 KB SRAM with 7-year lithium battery backup; 1 MB EPROM (firmware/monitor); 8K x 8 NVRAM + battery-backed RTC |

| VMEbus Interface | A32/D32 VMEbus Rev B/C; master/slave operation; enhanced DMA (supports burst transfers up to 12 MB/s); No D64 bus support |

| I/O Interfaces | 2x EIA-232-D/422 serial ports (configurable as DTE/DCE); 1x Centronics parallel port; 1x 16-bit Industry Pack® port (single slot, for limited expansion) |

| Optional Interfaces | 10/100Base-T Ethernet (RJ45, TCP/IP); SCSI-2 interface (for external storage); 1x debug port (advanced diagnostics) |

| Timers | 6x 32-bit general-purpose timers; 1x programmable watchdog timer (auto-reset on fault) |

| Physical Dimensions | 6U VMEbus form factor; single VME slot occupancy; weight: ~480 g; conformal coating (standard for industrial variants) |

| Power Requirements | +5 VDC (±5%), 3.2 A typical, 4.2 A maximum (with Ethernet); Operating temperature: -10 °C to +70 °C (14 °F to 158 °F); Storage temperature: -40 °C to +85 °C |

| Safety & Compliance | UL 1950; CSA C22.2 No. 950; EN 60950; FCC Class A (industrial EMC); IEC 61000-6-2 (enhanced EMC immunity); RoHS 3 |

| Diagnostic Features | Advanced on-board diagnostic firmware; 4-stage VMEbus interrupt handler; LED indicators (power, VME activity, Ethernet, fault); Remote monitoring via debug/Ethernet |

| Target Applications | Scaling packaging lines; multi-sensor process control (chemical, water); advanced small robotics; legacy manufacturing data aggregation |

Motorola MVME162-012

Product introduction

The Motorola MVME162-13 is an enhanced mid-tier VMEbus embedded controller designed by Motorola to address the gap between the cost-optimized Motorola MVME162-10 and fully featured Motorola MVME162-012. Unlike the MVME162-10 (fixed memory, no Industry Pack® support), Motorola MVME162-13 adds critical scalability: expandable DRAM (up to 16 MB), a single Industry Pack® port, and an optional Ethernet interface—all while avoiding the MVME162-012’s premium price tag and overkill features (e.g., D64 VMEbus).

A defining value of Motorola MVME162-13 is its ability to grow with mid-scale systems. For users operating packaging lines adding more sensors, or water treatment plants expanding to 5+ pump stations, Motorola MVME162-13 eliminates the need to replace the entire controller when requirements change. Its optional FPU (via MC68040 upgrade) handles emerging complex tasks (e.g., PID tuning for multi-loop control), while the Ethernet option enables remote monitoring—capabilities the MVME162-10 lacks. In scaling systems, Motorola MVME162-13 acts as a “bridge”—extending equipment life by 8–10 years without the cost of jumping to the MVME162-012 or modern SBCs.

Core advantages and technical highlights

Expandable DRAM for Growing Data Needs: Unlike the Motorola MVME162-10 (fixed 4 MB DRAM), Motorola MVME162-13 supports up to 16 MB DRAM—critical for applications adding more sensors or complex logic. A 1990s-era beverage bottling plant upgrades from MVME162-10 to Motorola MVME162-13 to manage 8 new pressure sensors (up from 2): expanding DRAM to 12 MB allows the controller to store 3 months of production data (vs. 2 weeks with the MVME162-10), eliminating daily data transfers and saving the plant $600 annually in labor. The enhanced DMA also speeds up data access, reducing sensor polling latency by 25%.

Optional Ethernet for Remote Monitoring: Motorola MVME162-13 offers a 10/100Base-T Ethernet option—absent from the MVME162-10—enabling real-time remote oversight. A rural water utility deploys Motorola MVME162-13 with Ethernet to monitor 6 filtration plants (up from 3): technicians access flow/pressure data via a cloud dashboard, avoiding monthly on-site visits (costing \(200 each). This cuts travel costs by \)1,200 annually, while the controller’s -10 °C operating range ensures reliability in winter—something the MVME162-10 (0 °C minimum) couldn’t provide.

Single Industry Pack® Port for Targeted Expansion: Motorola MVME162-13 adds a 16-bit Industry Pack® port (vs. none in the MVME162-10) for modular I/O upgrades. A small automotive parts plant uses the port to add a digital I/O module, controlling 8 new robotic grippers (up from 2): this avoids replacing the entire controller or adding external converters (saving $1,500 vs. upgrading to MVME162-012). The Industry Pack®’s hot-swap capability also allows module replacement without shutting down the line—reducing downtime by 40% compared to the MVME162-10’s hardwired I/O.

Optional FPU for Complex Calculations: Unlike the MVME162-10 (fixed MC68LC040), Motorola MVME162-13 supports an MC68040 upgrade (adds FPU) for advanced tasks. A chemical plant uses the FPU-equipped MVME162-13 to run multi-loop PID control for a mixing tank: the FPU accelerates concentration calculations by 60% vs. the MVME162-10, reducing chemical waste by 15% (saving $25k annually). The upgrade is field-installable, allowing the plant to add FPU capability only when needed—avoiding the MVME162-012’s upfront cost.

Typical application scenarios

In scaling packaging automation, a 1995 food packaging plant uses Motorola MVME162-13 to upgrade its MVME162-10-powered snack bagging line. The controller’s expanded 16 MB DRAM stores data from 10 new weight sensors (monitoring bag fill levels), while the Industry Pack® port adds a barcode scanner module (tracking product batches). Optional Ethernet connects the MVME162-13 to the plant’s MES system, enabling real-time production tracking—something the MVME162-10 couldn’t support. The plant avoids replacing the \(30k bagging machine by upgrading the controller, cutting waste from overfilled bags by 20% and saving \)40k annually.

In multi-site water treatment, a regional utility deploys Motorola MVME162-13 across 8 remote pump stations (up from 3 with the MVME162-10). Each controller connects to 4 pressure/flow sensors (via serial ports) and uses Ethernet to send data to a central Motorola MVME167-034A. The MVME162-13’s -10 °C operating range withstands winter temperatures, while its 7-year battery-backed SRAM retains 2 years of maintenance logs (vs. 1 year with the MVME162-10). The utility saves \(8k in annual maintenance costs (fewer site visits) and avoids \)50k in modernization by reusing existing sensor infrastructure.

Motorola MVME162-012

Related model recommendations

Motorola MVME162-10: Cost-optimized sibling with fixed specs. Predecessor to Motorola MVME162-13—upgrade when systems need expandable memory/Ethernet.

Motorola MVME162-012: Full-featured variant with D64 VMEbus. Upgrade for Motorola MVME162-13 if applications require 4 Industry Pack® ports or D64 DMA.

Motorola MVME350: VME I/O expansion module. Complements Motorola MVME162-13—adds extra serial/parallel ports for sensor networks beyond 8 devices.

Emerson MVME162-13 Upgrade Kit: Includes 16 MB DRAM SIMM and MC68040 FPU. Enhances Motorola MVME162-13’s performance for scaling systems.

Phoenix Contact QUINT-PS/1AC/5DC/5: 5 VDC power supply. Matches Motorola MVME162-13’s higher power needs (with Ethernet/FPU).

Schroff 6U VME Chassis (3-slot): Enclosure fits Motorola MVME162-13, Industry Pack® module, and MVME350 for full-scale setups.

Advantech IP-3120: 16-bit Industry Pack® digital I/O module. Paired with Motorola MVME162-13—adds 16 I/O channels for robotic control.

Cisco IE-2000-8P: Industrial Ethernet switch. Connects multiple Motorola MVME162-13 controllers to a central network (e.g., utility pump stations).

Wind River VxWorks 4.x: Industrial RTOS optimized for Motorola MVME162-13. Supports Ethernet and expanded memory for data aggregation.

Seagate ST34573N: 4.5 GB SCSI-2 hard drive. Optional for Motorola MVME162-13—stores 1 year of production data for compliance logging.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing Motorola MVME162-13, power off the VMEbus chassis and wear an ESD wristband. Verify the chassis supports A32/D32 VMEbus Rev B/C and has sufficient power (4.2 A max with Ethernet/FPU). Gather tools: torque screwdriver, Cat5e Ethernet cable (if using optional interface), 16 MB DRAM SIMM (for expansion), and multimeter (check +5 VDC ±5%). For Industry Pack® modules, ensure the slot is aligned with the controller’s connector—avoid forcing the module to prevent pin damage. When upgrading from MVME162-10, reuse existing serial/parallel wiring but update EDS files in the PLC to recognize Motorola MVME162-13’s new features.

Maintenance suggestions

Conduct semi-annual maintenance on Motorola MVME162-13: 1) Check LEDs—green power, blinking Ethernet/VME activity, no red fault = normal; 2) Use Ethernet/debug port to run advanced diagnostics (test DRAM expansion and Industry Pack® communication); 3) Clean dust from CPU/FPU heatsinks with compressed air (higher pressure for FPU if installed). Replace the SRAM/RTC battery every 6–7 years (Emerson part number 50001459-019). For troubleshooting, if Ethernet fails, verify switch configuration; if Industry Pack® communication drops, reseat the module. Store a spare Motorola MVME162-13 with matching DRAM/FPU config to minimize downtime for scaling systems.

Service and guarantee commitment

Emerson provides enhanced legacy support for Motorola MVME162-13, tailored to its role in scaling mid-scale systems. The standard warranty is 3 years (1 year longer than MVME162-10), covering core components and optional features (Ethernet/FPU). For users with growing operations, the Scalable Legacy Support Plan extends coverage to 5 years, offering 24/5 technical support (6-hour response time for Ethernet/FPU issues) and free access to upgrade kits (e.g., 16 MB DRAM).

Customers receive a dedicated resource library for Motorola MVME162-13, including expansion guides, Industry Pack® compatibility charts, and Ethernet configuration templates. Repairs follow a flat-rate service ($220 per unit—22% lower than MVME162-012) with a 5-day turnaround. This commitment reflects Emerson’s understanding that Motorola MVME162-13 powers evolving legacy systems—and its goal to support seamless scaling without compromising reliability.