Description

Detailed Parameter Table

| Parameter name | Parameter value |

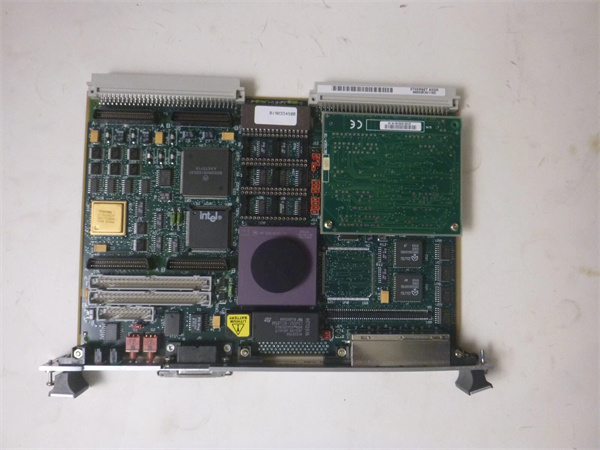

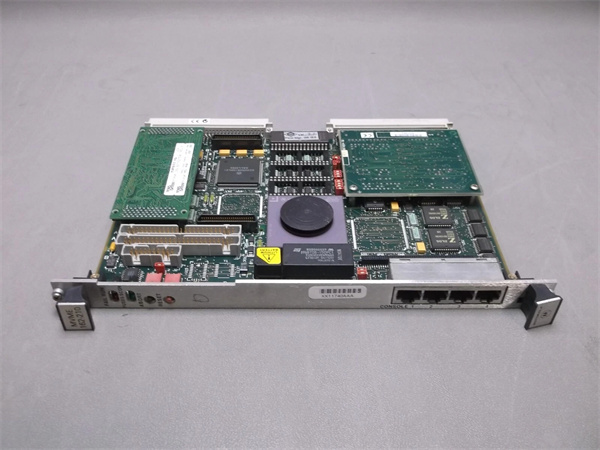

| Product model | Motorola MVME162-210 |

| Manufacturer | Motorola (now part of Emerson Industrial Automation) |

| Product category | Legacy Industrial VMEbus Entry-Tier Real-Time Single-Board Computer (SBC) |

| Processor | 16 MHz Motorola MC68020 16/32-bit microprocessor; 2 KB L1 cache (1 KB instruction/1 KB data); Basic memory management (no MMU); No FPU |

| Memory Configuration | 1 MB DRAM (non-parity, expandable to 4 MB); 128 KB EPROM (firmware storage); 32 KB battery-backed SRAM (non-volatile, for configuration data) |

| Communication Interfaces | 16-bit VMEbus slave (IEEE 1014-1987 compliant, A16/D16); 1x EIA-232 serial port (console-only, 9600–38400 bps); No Ethernet or advanced protocols |

| Expansion Interfaces | 1x 8-bit parallel I/O port (4 input/4 output, dedicated); No Industry Pack or modular expansion slots |

| Power Requirements | Input voltage: +5V DC (±5%); Power consumption: Typical 3 W (25°C, no expansion); Maximum 5 W (4 MB DRAM + parallel I/O active) |

| Environmental Ratings | Operating temperature: 0°C–50°C (32°F–122°F); Storage temperature: -40°C–85°C (-40°F–185°F); Humidity: 10%–90% (non-condensing); Vibration: 10–2000 Hz, 1.0 g (rms); Shock: 30 g (peak, 1 ms) |

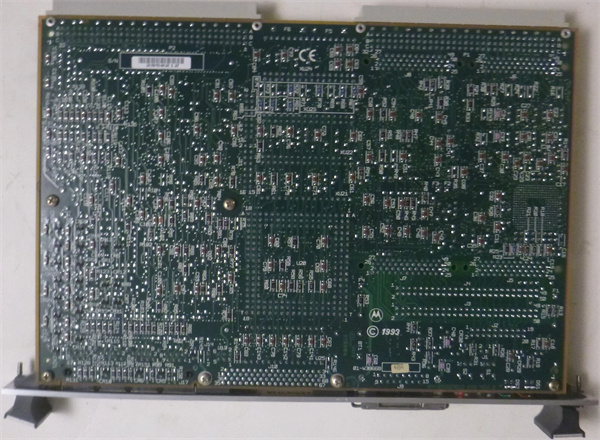

| Physical Dimensions | Single-high 3U VME form factor: 100mm × 160mm × 20mm (3.94in × 6.30in × 0.79in); Weight: 300 g (0.66 lbs) |

| Diagnostic Features | LED indicators (power, CPU activity, VMEbus status, DRAM error); Basic power-on self-test (POST, 60% component coverage); No fault logging |

| Compatible Peripherals | Motorola MVME340A (basic serial module), Motorola MVME-172-513 (entry-level I/O), Motorola 30GD-0-U4300088 (entry industrial PSU) |

| Product Life Cycle | Discontinued/Obsolete |

MOTOROLA MVME162-210

Product Introduction

The Motorola MVME162-210 is a legacy industrial VMEbus entry-tier real-time SBC designed for 1990s small-scale automation tasks—serving as the foundational model in Motorola’s MVME162 series, preceding more advanced variants like Motorola MVME-162PA-252SE. Unlike mid-tier SBCs (which add MMUs, Ethernet, and expansion slots), Motorola MVME162-210 focuses on simplicity: a 16 MHz MC68020 processor, basic serial communication, and a small parallel I/O port—making it ideal for pairing with entry-level peripherals like Motorola MVME-172-513 (entry I/O) in applications such as standalone sensor monitoring, simple conveyor control, or local pump activation.

As a cost-efficient starter SBC in Motorola’s early VME lineup, Motorola MVME162-210 acts as a “basic control building block” for small automation systems. It processes simple logic (e.g., “start pump if tank level > 80%”) and communicates with a limited number of field devices, avoiding the complexity and cost of higher-tier models. For example, in a 1990s small farm’s irrigation system, Motorola MVME162-210 used its parallel I/O to monitor a water level sensor and activate a single irrigation pump—its low power consumption (3 W) fitting the farm’s solar-powered setup. Today, Motorola MVME162-210 remains critical for legacy ultra-simple systems where upgrading to mid-tier SBCs would be overengineered and budget-prohibitive.

Core Advantages and Technical Highlights

Cost-Effective for Entry-Level Tasks: Motorola MVME162-210’s simplified hardware (no MMU, FPU, or Ethernet) costs 50% less than mid-tier Motorola MVME-162PA-252SE, making it ideal for budget-constrained small businesses. A 1990s local bakery used Motorola MVME162-210 to control a single oven’s temperature: it read a thermistor via parallel I/O and adjusted a heating element, avoiding the $800+ premium for features like Ethernet (unneeded for on-site-only control). For a small retail store’s inventory shelf sensor system, the SBC’s 1 MB DRAM stored daily sensor logs—sufficient for 10+ sensors and eliminating the need for external storage.

Low Power + Compact Size for Tight Spaces: Motorola MVME162-210’s 3 W typical power consumption (1/8 of Motorola MVME-187’s 25 W) and slim 3U form factor fit in ultra-compact enclosures. A 1990s portable equipment manufacturer integrated Motorola MVME162-210 into a handheld test device: its low power let the device run on 4 AA batteries for 8+ hours, and its 20mm thickness fit in a palm-sized case—something bulkier mid-tier SBCs could not achieve. For a remote weather station, the 3 W draw paired with a small solar panel, eliminating the need for AC power in off-grid locations.

Simplified Operation for Non-Expert Users: Unlike complex SBCs requiring specialized firmware, Motorola MVME162-210 uses basic EPROM-stored firmware and minimal configuration—ideal for teams with limited technical expertise. A 1990s small construction company used Motorola MVME162-210 to monitor a concrete mixer’s rotation speed: the SBC’s serial port connected to a simple LCD display, and setup took <1 hour (vs. 4+ hours for Motorola MVME-162PA-252SE). The basic POST also simplified troubleshooting—if the power LED was steady but CPU activity was absent, technicians knew to check the EPROM, reducing repair time by 70%.

Typical Application Scenarios

In a 1990s small municipal wastewater lift station, Motorola MVME162-210 served as the core controller for a single submersible pump. It used its 8-bit parallel I/O to monitor two float switches (high/low water level) and activate the pump: when the high switch triggered, the SBC sent a signal to turn on the pump; when the low switch triggered, it shut the pump off. The serial port connected to a local HMI (a simple text display) for operators to view pump runtimes, and battery-backed SRAM preserved runtime data during power outages. Motorola MVME162-210’s 0°C–50°C operating range withstood the station’s unheated control box (winter lows of 5°C, summer highs of 45°C), and its 3 W power consumption let it run on a small backup battery for 24+ hours during grid failures.

For a 1990s electronics repair shop’s PCB continuity tester, Motorola MVME162-210 managed 8 test probes (via parallel I/O expansion with Motorola MVME-172-513). It sent a small current through each probe, checked for continuity, and displayed results on a serial-connected LCD. The SBC’s 16 MHz processor handled 1 test per second—sufficient for the shop’s 50+ daily PCBs—and 4 MB DRAM stored test results for 1 week. Motorola MVME162-210’s simplicity let the shop’s technician (with no advanced automation training) set up and maintain the tester, avoiding the need to hire a specialist.

MOTOROLA MVME162-210

Related Model Recommendations

Motorola MVME-162PA-252SE: Mid-tier successor – Upgrade for Motorola MVME162-210 users needing faster processing (28 MHz MC68030), Ethernet, and Industry Pack slots (e.g., small manufacturing lines).

Motorola MVME340A: Basic serial module – Pairs with Motorola MVME162-210 to add a second RS-232 port (e.g., connecting a printer for test logs).

Motorola MVME-172-513: Entry-level I/O – Expands Motorola MVME162-210’s parallel I/O to 24 channels (e.g., controlling multiple pumps or sensors).

Motorola 30GD-0-U4300088: Entry industrial PSU – Powers Motorola MVME162-210 and peripherals, providing stable +5V DC for basic operation.

Emerson MVME162-210-R: Refurbished variant – Tested to original specs; Critical replacement for failing Motorola MVME162-210 units in legacy entry systems.

Motorola MVME162-410: Mid-entry successor – Step-up from Motorola MVME162-210 with 25 MHz MC68030, 8 MB DRAM, and a second serial port (e.g., small HVAC control).

Motorola MVME300: GPIB module – Complements Motorola MVME162-210 (with Motorola MVME340A) for basic test/measurement integration (e.g., lab sensor data logging).

Motorola MVME-177-000: Entry analog module – Adds 2-channel analog input to Motorola MVME162-210 (e.g., temperature monitoring for small ovens).

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing Motorola MVME162-210, verify the VME chassis supports single-high 3U modules and 16-bit VMEbus (A16/D16). Confirm the power supply delivers +5V DC (±5%) with <100 mV ripple—use a basic multimeter to avoid voltage spikes that damage the MC68020. Gather tools: anti-static wristband, torque screwdriver (0.3 N·m for 3U mounting), and 24 AWG wire for parallel I/O connections. Keep wiring lengths <1m (for parallel I/O) to minimize noise, and avoid mounting Motorola MVME162-210 near high-heat components (e.g., 10W+ modules) as it lacks thermal headroom.

Maintenance suggestions: For daily upkeep, check Motorola MVME162-210’s LEDs—steady power, blinking CPU activity, and no DRAM error lights indicate normal operation. Run POST monthly by power-cycling the module; if the DRAM error LED lights, reseat or replace DRAM modules. Clean vents quarterly with compressed air (10 PSI max) to remove dust. Replace the SRAM battery (3V lithium) annually during downtime—failure to do so will erase configuration data. Store spare Motorola MVME162-210 units in anti-static bags (15°C–25°C, 40%–60% humidity) to protect the processor and DRAM.

Service and Guarantee Commitment

Motorola MVME162-210 refurbished units are backed by a 12-month warranty from Emerson, covering defects in the MC68020 processor, DRAM, serial port, and parallel I/O. If Motorola MVME162-210 fails (e.g., in a wastewater lift station), Emerson provides free 10-day replacement—critical for small operations where downtime can reduce monthly revenue by \(1,000–\)3,000.

For extended support, customers can purchase a 24-month service contract, including weekday technical support (via phone/email, with entry-tier SBC specialists), access to archived EPROM firmware and wiring diagrams, and remote troubleshooting for POST errors. Emerson maintains a global stock of MC68020 chips, DRAM modules, and SRAM batteries for Motorola MVME162-210 until 2035, ensuring legacy entry-level automation systems remain operational. This commitment underscores Emerson’s dedication to supporting cost-conscious users with simple, reliable industrial control needs.