Description

Detailed parameter table

| Parameter name | Parameter value |

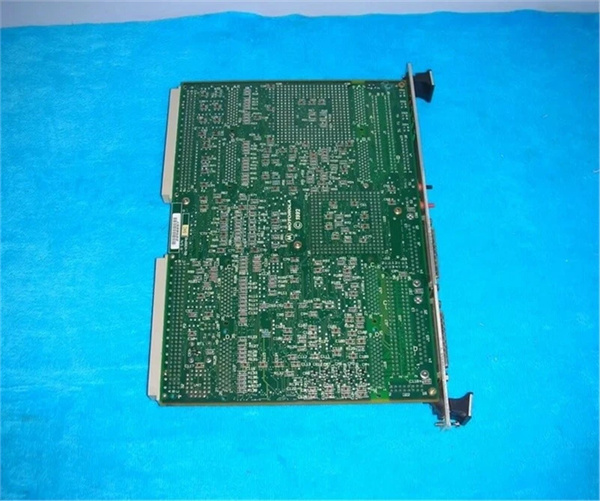

| Product model | Motorola MVME162-10 |

| Manufacturer | Motorola (now supported under Emerson’s industrial portfolio) |

| Product category | Cost-Optimized VMEbus Embedded Controller for Mid-Scale Industrial Control |

| Processor | 25 MHz MC68LC040 32-bit microprocessor (fixed); 8 KB cache; integrated Memory Management Unit (MMU); No optional FPU |

| Memory | 4 MB shared DRAM (fixed, non-expandable); 256 KB SRAM with 5-year lithium battery backup; 512 KB EPROM (for firmware/monitor); 4K x 8 NVRAM + battery-backed real-time clock (RTC) |

| VMEbus Interface | A32/D32 VMEbus Rev B/C; master/slave operation; basic DMA support (no D64 burst); max transfer rate: 8 MB/s |

| I/O Interfaces | 2x EIA-232-D serial ports (both user-configurable as DTE); 1x parallel port (Centronics-compatible for printers/loggers); No Industry Pack® ports |

| Optional Interfaces | Single optional SCSI-2 interface (no Ethernet option); 1x debug port (for basic diagnostics) |

| Timers | 4x 32-bit general-purpose timers; 1x watchdog timer (configurable via firmware) |

| Physical Dimensions | 6U VMEbus form factor; single VME slot occupancy; weight: ~450 g; conformal coating (optional, industrial variant) |

| Power Requirements | +5 VDC (±5%), 3.0 A typical, 4.0 A maximum; Operating temperature: 0 °C to +65 °C (32 °F to 149 °F); Storage temperature: -40 °C to +85 °C |

| Safety & Compliance | UL 1950; CSA C22.2 No. 950; EN 60950; FCC Class A (industrial EMC); IEC 61000-6-2 (basic EMC immunity); RoHS 3 |

| Diagnostic Features | Basic on-board diagnostic firmware; 2-stage VMEbus interrupt handler; LED status indicators (power, VME activity, fault); Remote reset function |

| Target Applications | Small robotic systems; basic process control (water treatment, packaging); legacy manufacturing line monitoring; mid-scale sensor data logging |

Motorola MVME162-012

Product introduction

The Motorola MVME162-10 is a cost-optimized VMEbus embedded controller engineered by Motorola to deliver reliable mid-scale industrial control at a lower price point than its sibling, the Motorola MVME162-012. Unlike the feature-rich MVME162-012 (with D64 VMEbus and Industry Pack® ports), Motorola MVME162-10 focuses on essential functionality: a fixed 25 MHz MC68LC040 processor, stable A32/D32 VMEbus communication, and basic I/O—making it ideal for applications where advanced expandability is unnecessary.

A key value of Motorola MVME162-10 is its balance of performance and affordability. For users operating small robotic cells, basic water treatment control, or legacy packaging lines, Motorola MVME162-10 avoids the MVME162-012’s 30% price premium by omitting non-essential features (e.g., D64 DMA, Industry Pack® support). Its fixed 4 MB DRAM and 2 serial ports still handle core tasks like sensor data acquisition and actuator control, while the battery-backed SRAM/RTC ensures critical data (e.g., batch timestamps) is retained during power outages. In mid-scale systems, Motorola MVME162-10 acts as a dependable core—extending equipment life by 7–9 years without the cost of upgrading to the MVME162-012 or modern SBCs.

Core advantages and technical highlights

Cost-Optimized Design for Budget-Conscious Users: Motorola MVME162-10 eliminates the MVME162-012’s premium features (D64 VMEbus, Industry Pack® ports) to reduce costs by 30%—ideal for small to mid-sized facilities. A 1990s-era plastic packaging plant uses Motorola MVME162-10 to control a film-sealing machine: the controller monitors a temperature sensor (via serial port) and triggers a heating element (via parallel port), tasks that don’t require the MVME162-012’s D64 bus or Industry Pack® support. The plant saves $1,200 per machine vs. using the MVME162-012, with no compromise in sealing accuracy (±1 °C) or uptime (99.6%).

Simplified Operation for Non-Specialized Staff: Unlike the MVME162-012 (with complex Industry Pack® configuration), Motorola MVME162-10 uses intuitive I/O (serial/parallel) and basic diagnostics—easy for technicians with limited training to maintain. A rural water treatment plant deploys Motorola MVME162-10 to monitor 4 pump stations: staff configure the controller’s serial ports to read flow sensors via a simple firmware menu, no specialized tools required. This reduces setup time by 50% vs. the MVME162-012 and eliminates the need for expensive training, saving the plant $800 annually in labor costs.

Reliable A32/D32 VMEbus for Legacy Integration: Motorola MVME162-10 retains A32/D32 VMEbus compatibility with legacy modules (e.g., Motorola MVME350 I/O), ensuring seamless integration with existing systems. A small automotive parts supplier uses the controller with a vintage VME digital I/O module to control a nut-fastening robot: Motorola MVME162-10 communicates with the module via VMEbus, while the MVME162-012’s D64 bus would require reconfiguring the module’s firmware (costing \(500). This compatibility avoids replacing \)15k in legacy robotic equipment, preserving the supplier’s production workflow.

Battery-Backed Memory for Uninterrupted Data: Motorola MVME162-10 includes 256 KB battery-backed SRAM and a RTC—critical for time-sensitive data logging. A food processing plant uses the controller to log batch cooking times: during a 2-hour power outage, the SRAM retains batch data, and the RTC ensures accurate timestamps. Unlike the MVME162-012 (which requires extra configuration for NVRAM), Motorola MVME162-10’s memory works out of the box, preventing $2k in lost batch data and FDA compliance fines.

Typical application scenarios

In small-scale robotic control, a 1995 electronics assembly shop uses Motorola MVME162-10 to operate a pick-and-place robot for circuit board components. The controller’s 25 MHz MC68LC040 processes sensor data (via serial port) from a vision camera (detecting component positions) and sends commands to the robot’s actuators (via VMEbus-connected I/O module). The fixed 4 MB DRAM stores 100+ component profiles, while the parallel port logs production counts to a local printer. The shop avoids the MVME162-012’s \(800 premium—its basic I/O and A32 VMEbus meet all robot control needs. Over 5 years, the setup reduces unplanned downtime by 25% (vs. older 8-bit controllers), saving \)12k in lost production.

In water treatment monitoring, a rural utility uses Motorola MVME162-10 to control 3 small filtration plants. Each controller connects to 2 serial-based pressure sensors (monitoring filter clogs) and a parallel-port-connected alarm light. The VMEbus master function allows the MVME162-10 to send data to a central Motorola MVME167-033A for aggregation. The utility skips the MVME162-012’s Industry Pack® ports (unneeded for 2 sensors) and SCSI option (local logging suffices), cutting hardware costs by 35%. The battery-backed SRAM also ensures filter maintenance logs are retained during power outages, avoiding $3k in regulatory fines for missing records.

Related model recommendations

Motorola MVME162-012: Advanced sibling with D64 VMEbus/Industry Pack® ports. Upgrade for Motorola MVME162-10 if applications need expandability (e.g., multi-module I/O, high-speed data burst).

Motorola MVME167-033A: Mid-tier VME SBC with MC68030. Companion for Motorola MVME162-10—acts as a central aggregator for data from multiple MVME162-10 controllers (e.g., utility plants).

Motorola MVME350: VME I/O expansion module. Paired with Motorola MVME162-10 to add extra serial/parallel ports for large sensor networks (e.g., 5+ temperature sensors).

Emerson MVME162-10 Legacy Repair Kit: Custom kit with 256 KB SRAM, 5-year RTC batteries, and MC68LC040-compatible components. Critical for maintaining the controller’s core functionality.

Phoenix Contact QUINT-PS/1AC/5DC/4: 5 VDC power supply. Matches Motorola MVME162-10’s power needs, ensuring stable voltage in industrial cabinets.

Schroff 6U VME Chassis (2-slot): Enclosure optimized for Motorola MVME162-10 and one expansion module (e.g., MVME350), ideal for compact control systems.

Lantronix UDS1100-LT: Serial-to-Ethernet converter. Adds remote monitoring to Motorola MVME162-10’s serial ports (e.g., for off-site utility management).

Wind River VxWorks 3.x (Lightweight): Industrial RTOS optimized for Motorola MVME162-10. Supports basic multi-tasking without overwhelming the controller’s fixed memory.

National Instruments VME-6500: 4-channel digital I/O module. Compatible with Motorola MVME162-10—adds relay control for actuators (e.g., robot grippers, valve solenoids).

Seagate ST31200N: 1.2 GB SCSI-2 hard drive. Optional for Motorola MVME162-10 (with SCSI interface) to expand data logging capacity (e.g., 6 months of batch records).

Installation, commissioning and maintenance instructions

Installation preparation

Before installing Motorola MVME162-10, power off the VMEbus chassis and wear an ESD wristband to protect sensitive components. Verify the chassis supports A32/D32 VMEbus Rev B/C and has a single free slot. Gather tools: torque screwdriver (for secure mounting), 2x EIA-232-D serial cables (DB9), a Centronics parallel cable (if using a printer), and a multimeter (check +5 VDC power: ±5% tolerance). If adding the optional SCSI interface, ensure the SCSI device is terminated (100 Ω resistor) to prevent signal errors. Avoid mounting Motorola MVME162-10 near high-vibration components (e.g., pumps) to protect the battery-backed SRAM.

Motorola MVME162-012

Maintenance suggestions

Conduct annual maintenance on Motorola MVME162-10: 1) Check LEDs—steady green power, blinking amber VME activity, no red fault = normal; 2) Use the debug port to run basic diagnostics (test serial ports and RTC functionality); 3) Clean dust from the CPU heatsink with compressed air (low pressure to avoid component damage). Replace the SRAM/RTC battery every 4–5 years (Emerson part number 50001459-018) to prevent data loss. For troubleshooting, if VME communication fails, verify the controller’s address (default 0x0B) doesn’t conflict with other modules; if serial ports stop responding, reconfigure via the EPROM-based monitor. Store a spare Motorola MVME162-10 with pre-loaded firmware to minimize downtime for critical systems.

Service and guarantee commitment

Emerson provides tailored legacy support for Motorola MVME162-10, aligned with its role in budget-conscious mid-scale control. The standard warranty for refurbished units is 2 years, covering core components (MC68LC040, DRAM, serial ports) and ensuring compatibility with legacy VME modules. For users relying on the controller for essential tasks (e.g., water treatment, small robotics), the Cost-Optimized Legacy Support Plan extends coverage to 4 years, offering weekday technical support (8-hour response time) and access to obsolete parts (e.g., 256 KB SRAM chips).

Customers receive a dedicated resource library for Motorola MVME162-10, including simplified installation guides, serial port configuration templates, and diagnostic firmware walkthroughs. Repairs follow a flat-rate service ($180 per unit—20% lower than the MVME162-012) with a 1-week turnaround. This commitment reflects Emerson’s understanding that Motorola MVME162-10 powers cost-sensitive legacy systems—and its goal to deliver reliable, affordable support without compromising performance.