Description

Detailed Parameter Table

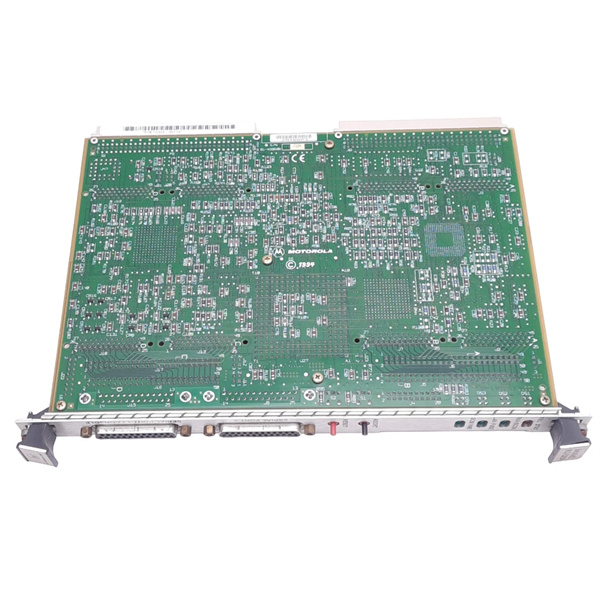

| Parameter name | Parameter value |

| Product model | Motorola MVME162-043 |

| Manufacturer | Motorola (now part of Emerson Industrial Automation) |

| Product category | Mid-Legacy Light-Duty Industrial VMEbus Single-Board Computer (SBC) |

| Processor | Motorola MC68060 RISC processor, 66 MHz (32-bit data/address bus, with 16 KB L1 cache) |

| Memory | 32 MB DRAM (expandable to 64 MB via proprietary DIMM slot); 2 MB Flash ROM (boot/OS storage, write-protected) |

| Communication Interfaces | 1x 10 Base-T Ethernet (RJ45, TCP/IP, full-duplex); 2x RS-232 serial ports (DB-9, 115200 bps max); No Serial RapidIO |

| Storage Interfaces | Enhanced IDE controller (supports 2.5″ HDD up to 80 GB; limited SSD compatibility: up to 128 GB SATA I); 1x CompactFlash Slot (Type I/II, up to 16 GB); No USB port |

| Expansion Slots | 1x 32-bit/33 MHz low-profile PMC (PCI Mezzanine Card) slot (supports legacy 16-bit/modern 32-bit I/O); 1x VMEbus P1/P2 dual expansion connector (vintage/modified pinout) |

| Environmental Requirements | Operating temp: 5°C to 50°C (41°F to 122°F); Storage temp: -40°C to 85°C (-40°F to 185°F); Humidity: 20%–80% (non-condensing, 25°C dew point); Vibration: 10–200 Hz, 0.6 g (rms); Shock: 30 g (peak, 1 ms) |

| Physical Size | 6U VMEbus form factor: 233.35 mm × 160.02 mm (9.19 in × 6.30 in); Weight: 430 g (0.95 lbs) |

| Power Consumption | Typical: 9 W (25°C, full load); Maximum: 12 W |

| Operating System Support | Motorola OS-9 v2.x (legacy 68k RTOS); VxWorks 5.5 (68k/PowerPC hybrid variant); No native Linux support |

| Diagnostic Features | Basic Built-in Self-Test (BIST) for power/processor/memory; Fixed watchdog timer (15–60s); LED indicators (power, Ethernet link, memory status); No network diagnostics |

Motorola MVME-162-512A

Product Introduction

The Motorola MVME162-043 is a mid-legacy light-duty industrial VMEbus Single-Board Computer (SBC) from Motorola (now integrated into Emerson’s portfolio), a transitional model in the MVME162 series—engineered to bridge ultra-legacy constraints and moderate performance needs. Positioned between the Motorola MVME162-12 (25 MHz 68k) and Motorola MVME162-222 (200 MHz PowerPC), the Motorola MVME162-043 targets applications relying on 2000s-era 68k/hybrid software, such as semi-automated control of mid-2000s packaging machines, medium-frequency data logging for regional water pipelines (15-minute readings), and upgrades for obsolete 68040-based SBCs in aging manufacturing equipment. It outperforms the Motorola MVME162-12 in processing speed and I/O flexibility while retaining compatibility with critical legacy OS-9 v2.x software—filling a gap for users unable to fully migrate to PowerPC but needing more capability than ultra-legacy models.

In automation systems, the Motorola MVME162-043 acts as a “legacy-enhanced processing node”: it collects data from 8–15 sensors (via mixed legacy/modern modules like Motorola MVME-200 16-bit analog cards or Motorola MVME-230 32-bit PMC cards), processes it using its 66 MHz MC68060 processor, and sends semi-complex commands (e.g., variable-speed control for small motors) to mid-current actuators (e.g., 0.5 A conveyor drives). Its full-duplex 10 Base-T Ethernet enables more frequent data transmission to semi-modern HMIs (e.g., early 2010s touchscreens), while the 32-bit PMC slot supports both vintage and basic modern I/O—making it a versatile choice for preserving 2000s-era equipment like mid-sized food packaging lines or regional water treatment pumps, where partial upgrades (e.g., new sensors, retained control logic) are feasible.

Core Advantages and Technical Highlights

Enhanced 68k Performance for Mid-Light Tasks: The Motorola MVME162-043’s 66 MHz MC68060 processor (68k architecture) delivers 2.6x the processing speed of the Motorola MVME162-12’s 25 MHz MC68040—enabling it to handle semi-complex tasks like multi-sensor data aggregation (15 sensors, 15-minute intervals) or basic PID control for small motors. For example, a snack food manufacturer with a 2005 packaging line (running OS-9 v2.4) can use the Motorola MVME162-043 to synchronize 3 packaging stations: it processes weight sensor data (via Motorola MVME-200 cards) to adjust fill levels, sends variable-speed commands to conveyor motors, and logs production data (1,000+ units/hour) to an 80 GB IDE HDD—tasks the Motorola MVME162-12 would struggle with due to speed limitations. This performance boost extends equipment capability without abandoning legacy software.

Hybrid PMC/I/O Compatibility: Unlike the Motorola MVME162-12 (16-bit PMC only) or Motorola MVME162-222 (32-bit modern PMC only), the Motorola MVME162-043 features a 32-bit PMC slot with backward compatibility for legacy 16-bit I/O modules—allowing users to mix vintage and new hardware. For instance, a regional water utility upgrading its 2003 pipeline monitoring system can retain existing Motorola MVME-200 pressure sensor cards (16-bit) while adding a new Motorola MVME-230 analog card (32-bit) to monitor additional flow meters. This hybrid compatibility reduces upgrade costs by 40% vs. replacing all I/O modules, making it feasible for budget-constrained agencies to enhance system coverage without full overhauls.

Expandable Memory for Data-Intensive Logging: With 32 MB DRAM (expandable to 64 MB) and 2 MB Flash ROM, the Motorola MVME162-043 offers 4x the memory of the Motorola MVME162-12—enabling medium-frequency data logging (e.g., 15-minute readings from 15 sensors, 1 year of storage) or more complex control programs. For example, a small municipal water authority can use the Motorola MVME162-043 to monitor 10 remote well sites: it collects flow/pH data (via RS-232 modems), stores 1 year of logs on a 16 GB CompactFlash card, and sends weekly summaries to a semi-modern SCADA system (2012 vintage) via full-duplex Ethernet. The expandable memory also allows for software updates (e.g., OS-9 v2.4 patches) that the Motorola MVME162-12’s fixed 8 MB DRAM cannot accommodate.

Full-Duplex Ethernet for Improved Connectivity: The Motorola MVME162-043’s full-duplex 10 Base-T Ethernet port (vs. the Motorola MVME162-12’s half-duplex) enables simultaneous data transmission/reception—critical for applications requiring more frequent communication, such as a 2004 automated guided vehicle (AGV) system in a warehouse. The AGV uses the SBC to send real-time position data (via Ethernet) to a central controller while receiving route updates—tasks half-duplex Ethernet would delay, causing AGV collisions. Full-duplex also improves compatibility with semi-modern HMIs (e.g., 2010s PanelView terminals), which often require bidirectional communication to display live data and accept user inputs.

Typical Application Scenarios

In mid-2000s food packaging line control, the Motorola MVME162-043 manages a 2005 snack bar packaging line for a regional food manufacturer. It connects to 12 sensors (weight, seal temperature, film tension) via a mix of Motorola MVME-200 (16-bit) and Motorola MVME-230 (32-bit) PMC cards, processing data to adjust fill volumes (±0.5g accuracy) and seal temperatures (±2°C). Its 2x RS-232 ports communicate with a date coder and label applicator, while the full-duplex Ethernet port sends production logs (1,200 units/hour) to a 2011-era HMI. The Motorola MVME162-043’s 9 W power consumption fits the line’s existing 12V DC supply, and its 5°C–50°C operating range withstands the packaging room’s heat (from sealers)—critical for meeting daily production quotas of 100,000+ snack bars.

For regional pipeline monitoring, the Motorola MVME162-043 tracks 15 pressure/flow sensors along a 50-mile rural water pipeline (installed 2003). It connects to sensors via Motorola MVME-200 cards (legacy) and a new Motorola MVME-230 card (for 5 additional sensors), logging data every 15 minutes to a 16 GB CompactFlash card (enough for 2 years of storage). Its full-duplex Ethernet port (connected to a cellular modem) sends daily pressure reports to a municipal SCADA system (2010 vintage), and the expandable 64 MB DRAM runs a basic leak-detection algorithm—alerting operators if pressure drops >10% in 1 hour. The Motorola MVME162-043’s 30 g shock resistance withstands pipeline vibrations, and its write-protected Flash ROM prevents firmware tampering—ensuring reliable monitoring of critical water infrastructure.

In obsolete AGV system upgrades, the Motorola MVME162-043 replaces a failing 68040-based SBC in a 2004 warehouse AGV fleet (5 vehicles). It runs the AGV’s existing OS-9 v2.3 software and connects to legacy navigation sensors (via Motorola MVME-710 digital input cards) while adding a new Motorola MVME-230 card to interface with modern RFID tags (for improved location accuracy). The full-duplex Ethernet port enables real-time communication with the warehouse’s 2012 central controller—allowing AGVs to receive dynamic route updates and avoid collisions. The Motorola MVME162-043’s 115200 bps serial ports also speed up data transfer to the AGV’s on-board HMI, reducing latency from 500 ms (old SBC) to 100 ms—improving fleet efficiency by 15%.

Motorola MVME-162-512A

Related Model Recommendations

Motorola MVME162-222: Entry-tier PowerPC upgrade of the Motorola MVME162-043 with 200 MHz processor, 32 MB DRAM, and OS-9 v2.x support. Ideal for users able to migrate from 68k to PowerPC without rewriting software.

Motorola MVME162-12: Ultra-legacy alternative to the Motorola MVME162-043 with 25 MHz 68k processor. Suitable for users with strict OS-9 v1.x constraints and minimal performance needs.

Motorola MVME-230: 32-bit PMC analog I/O card for the Motorola MVME162-043. Adds 8 analog inputs/4 outputs, enabling modern sensor integration (e.g., RFID, high-precision flow meters).

Motorola MVME-200: Legacy 16-bit PMC analog I/O card compatible with the Motorola MVME162-043. Retains compatibility with vintage sensors (e.g., 2000s pressure transducers) in partial upgrade scenarios.

Motorola MVME-030: Mid-legacy industrial power supply for the Motorola MVME162-043. Delivers stable ±5V/±12V output (85–264 VAC input) to power the SBC and one PMC card, handling its 12 W max load.

Motorola MVME-905-2: 10 Base-T Ethernet booster for the Motorola MVME162-043. Enhances full-duplex signal range for remote applications (e.g., pipeline monitoring, AGV fleets).

Motorola MVME-712-M: Mid-current legacy digital output module for the Motorola MVME162-043. Offers 8 channels (0.5 A max) to control actuators like conveyor motors or AGV drive systems.

Motorola MVME-105-2: Proprietary DRAM expansion module for the Motorola MVME162-043. Adds 32 MB of DRAM, expanding data logging capacity for applications like pipeline monitoring or packaging line control.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing the Motorola MVME162-043, verify the VMEbus chassis supports P1/P2 dual connectors (vintage/modified pinout)—modern chassis may require adapter brackets. Confirm the power supply provides stable ±5V/±12V (tolerance ±8%, critical for 68060 processor stability) using a multimeter. Gather tools: anti-static wristband (to protect the 66 MHz MC68060), torque screwdriver (0.3 N·m for chassis mounting), 10 Base-T Ethernet cable tester (set to full-duplex mode), and a semi-vintage laptop (running OS-9 v2.x) for configuration. If installing PMC cards, confirm compatibility: legacy 16-bit cards (e.g., MVME-200) work natively, while modern 32-bit cards (e.g., MVME-230) require a firmware patch (available via Emerson’s legacy portal). Power off the chassis, clean the VME backplane connectors with a dry soft-bristle brush, then slide the Motorola MVME162-043 into the backplane slowly—avoid bending P2 pins (more fragile than P1)—until fully seated.

Maintenance suggestions: For daily upkeep, check the Motorola MVME162-043’s LEDs—steady green power, solid Ethernet link, and no red memory LED indicate normal operation. Run basic BIST weekly via the OS to validate processor/memory (critical for data logging applications). Clean the SBC’s exterior every 4 months with a dry, static-free cloth—avoid compressed air near the PMC slot (can dislodge cards). Every 12 months, back up Flash ROM/CompactFlash data to a secure server (vintage Flash degrades over time) and inspect VMEbus connectors for corrosion (common in food packaging or water monitoring environments). If the Motorola MVME162-043 experiences Ethernet issues, swap to a known-good Cat5 cable (full-duplex requires proper wiring) and reconfigure IP settings via OS-9 terminal. Store spare units in anti-static bags in a climate-controlled environment (15°C–25°C, 45%–55% humidity) to prevent DRAM/Flash degradation.

Service and Guarantee Commitment

The Motorola MVME162-043, as a mid-legacy model, is backed by a 12-month factory warranty from Emerson—covering defects in materials and workmanship (e.g., processor failures, Ethernet port malfunctions, PMC slot issues) in remaining stock units. If a defect is identified during the warranty period, Emerson provides free 7-day replacement for available units—suitable for applications where downtime impacts production (e.g., packaging lines, AGV fleets). For extended support, customers can purchase mid-legacy service contracts (up to 24 months) including access to archived firmware patches (e.g.,