Description

Detailed Parameter Table

**

| Parameter name | Parameter value |

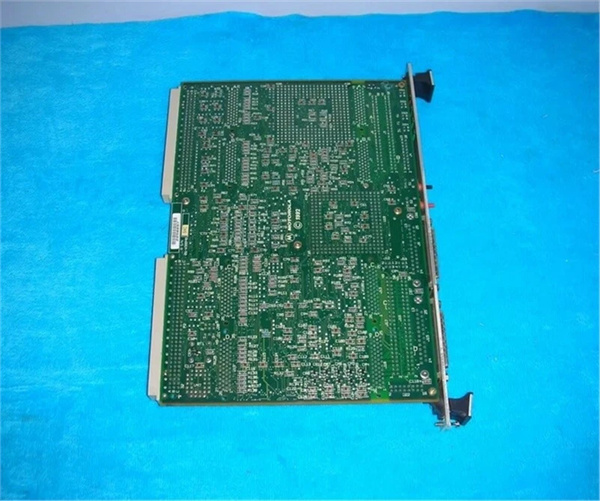

| Product model | Motorola MVME162 – 012 |

| Manufacturer | Motorola (now part of Emerson Industrial Automation) |

| Product category | Industrial VMEbus – based Single – Board Computer (SBC) |

| Processor | 25 MHz Motorola MC68LC040 enhanced 32 – bit microprocessor; 8 KB cache; Memory Management Unit (MMU) |

| Memory Configuration | 4 MB of shared DRAM (expandable); 512 KB SRAM with battery backup; 1 MB of flash memory for on – board monitor/debugger or user – installed firmware; 8 K x 8 non – volatile RAM (NVRAM) and clock with battery backup |

| Communication Interfaces | 1x Ethernet transceiver interface with 32 – bit local bus DMA; Two serial communication ports – console port as EIA – 232 – D DTE, second port user – configurable for EIA – 232 – D/EIA – 422 (V.36) DTE/DCE |

| Expansion Interfaces | Four 16 – or 32 – bit Industry Pack® ports, one DMA channel per port; 32 – bit VMEbus master/slave interface with system controller functionality; High – performance DMA support for VMEbus D64 and local bus memory burst cycles |

| Power Requirements | Input voltage: +5V DC (±5%); Power consumption varies based on configuration, typically in the range of 3 – 5 W |

| Environmental Ratings | Operating temperature: 0°C – 50°C; Storage temperature: – 40°C – 85°C; Humidity: 5% – 95% (non – condensing); Vibration: 10 – 2000 Hz, 0.5 g (rms); Shock: 20 g (peak, 1 ms) |

| Physical Dimensions | Double – high VME form factor; Dimensions: 233.35mm x 160mm (approximate, subject to variation); Weight: Approximately 1 – 1.5 kg (estimated) |

| Diagnostic Features | On – board debugger and diagnostic firmware; LED indicators for power, network activity, and basic system status; Six 32 – bit timers (four without VMEbus) and watchdog timer |

| Compatible Peripherals | A wide range of Industry Pack modules for I/O expansion, such as analog – to – digital converters, digital I/O modules, and communication modules; SCSI bus interface module (optional) for storage connectivity |

| Product Life Cycle | In a legacy/end – of – life state, but still in use in some industrial and embedded systems |

MOTOROLA MVME162-012

Product Introduction

The Motorola MVME162 – 012 is an industrial – grade VMEbus – based Single – Board Computer (SBC) that was designed to meet the demanding requirements of embedded and industrial control applications. Powered by a 25 MHz Motorola MC68LC040 enhanced 32 – bit microprocessor, it offers a balance of performance and reliability.

This model is an evolution within Motorola’s MVME162 series. Compared to some of its predecessors like the MVME162 – 10, it brings significant upgrades in processing power, memory capacity, and connectivity options. The MVME162 – 012 was a popular choice in the 1990s and early 2000s for applications where high – speed data processing, real – time control, and expandability were crucial. Despite being in a legacy state, it still serves as a critical component in many long – standing industrial systems that have not been upgraded due to the high cost of replacing both hardware and associated software.

Core Advantages and Technical Highlights

Powerful Processing Performance: The 25 MHz MC68LC040 processor, combined with its 8 KB cache and MMU, enables the MVME162 – 012 to handle complex computational tasks efficiently. For instance, in industrial control systems where real – time data analysis of sensor readings is required, the processor can quickly process large volumes of data. In a manufacturing plant, it can analyze data from multiple temperature, pressure, and vibration sensors simultaneously, making it possible to detect and respond to equipment malfunctions in a timely manner. This processing power also allows for smooth operation of multitasking real – time operating systems, which are often necessary for coordinating various industrial processes.

Rich Memory Configuration: With 4 MB of shared DRAM (expandable), 512 KB of battery – backed SRAM, and 1 MB of flash memory, the MVME162 – 012 provides ample storage for both data and firmware. The battery – backed SRAM ensures that critical configuration data and real – time clock information are retained even during power outages. In a telecommunications switching system, the flash memory can store the system’s operating software and configuration settings, while the DRAM is used for high – speed data buffering during call processing. This memory configuration allows for seamless operation and quick access to data, enhancing the overall system performance.

Versatile Connectivity and Expansion: The inclusion of an Ethernet transceiver interface with 32 – bit local bus DMA enables high – speed network communication. This is extremely useful in applications where remote monitoring and control are required, such as in a power distribution network where the MVME162 – 012 can communicate with a central control station over an Ethernet network to transmit data on power consumption, voltage levels, and equipment status. The four Industry Pack ports offer extensive expansion capabilities. For example, in a laboratory automation system, additional Industry Pack modules can be added to the MVME162 – 012 to interface with various scientific instruments, such as spectrometers, oscilloscopes, and robotic arms, allowing for comprehensive control and data acquisition.

Typical Application Scenarios

Industrial Automation and Control: In a large – scale manufacturing facility, the MVME162 – 012 can be used to control an entire production line. It can interface with programmable logic controllers (PLCs), sensors, and actuators via its Industry Pack ports and serial communication ports. For example, it can monitor the position of conveyor belts, the status of robotic assembly arms, and the quality of products passing through inspection stations. Based on the data received, it can send control signals to adjust the speed of conveyor belts, activate or deactivate robotic arms, and trigger alarms in case of product defects. The Ethernet interface allows for remote monitoring and control by plant managers, enabling them to make real – time adjustments to the production process from a central control room.

Telecommunications Infrastructure: In a mobile phone base station, the MVME162 – 012 can be used for signal processing and control functions. It can handle tasks such as call routing, signal modulation and demodulation, and communication with other network elements. The high – speed processing power of the MC68LC040 processor is essential for processing the large volumes of data associated with mobile communication. The battery – backed SRAM ensures that critical network configuration data is not lost during power disruptions, maintaining the integrity of the base station’s operation. The Ethernet interface enables seamless communication with other components in the telecommunications network, such as mobile switching centers and other base stations.

Scientific Research and Laboratory Automation: In a research laboratory, the MVME162 – 012 can be the central control unit for a complex experimental setup. It can control multiple scientific instruments simultaneously, such as a mass spectrometer, a gas chromatograph, and a fluorescence microscope. By connecting to these instruments via Industry Pack modules and serial ports, it can automate the data acquisition process, analyze the data in real – time, and store the results in its memory. The Ethernet interface allows researchers to access the experimental data remotely, collaborate with colleagues in different locations, and integrate the experimental results into a larger research project.

MOTOROLA MVME162-012

Related Model Recommendations

Motorola MVME162 – 200: This model offers further enhancements in processing power, with potentially a faster clock speed or more advanced features in the microprocessor. It may be suitable for applications that require even higher computational performance, such as high – speed data analysis in financial trading systems or complex simulations in engineering research.

Motorola MVME162 – 322: With different memory configurations and additional I/O options, the MVME162 – 322 can be a good choice for applications where more extensive memory or specific I/O requirements are needed. For example, in a data – logging application that requires large amounts of storage for long – term data retention, the MVME162 – 322’s enhanced memory capabilities could be beneficial.

Motorola MVME712 Series Conversion Modules: These modules are designed to work in conjunction with the MVME162 series, including the MVME162 – 012. They can provide additional standard I/O connections, allowing for easier integration with a wider range of external devices. In an industrial control system where there is a need to interface with legacy equipment that uses non – standard I/O protocols, the MVME712 series conversion modules can bridge the gap.

Industry Pack Modules: A wide variety of Industry Pack modules are available, such as analog – to – digital converters, digital I/O modules, and communication modules. These can be added to the MVME162 – 012 to expand its functionality according to specific application requirements. For example, if an application requires additional analog input channels for sensor data acquisition, an analog – to – digital converter Industry Pack module can be installed.

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Before installing the MVME162 – 012, ensure that the VME chassis is compatible with double – high VME modules and supports the required VMEbus specifications. Check the power supply to ensure it can provide a stable +5V DC (±5%) with a low ripple factor, as the MVME162 – 012 is sensitive to power fluctuations. Use an anti – static wristband and proper ESD – safe tools during installation to prevent damage to the sensitive electronic components. When connecting external devices, such as Industry Pack modules, follow the manufacturer’s guidelines for proper cabling and connection procedures. Ensure that all cables are securely fastened to prevent disconnection during operation.

Maintenance Suggestions: Regularly check the LED indicators on the MVME162 – 012 to monitor the system’s status. A steady power LED indicates proper power supply, while a blinking network activity LED shows that the Ethernet interface is functioning correctly. Periodically run the on – board diagnostic firmware to check for any hardware issues. Clean the board and its components regularly to prevent dust accumulation, which can cause overheating. Replace the battery in the battery – backed SRAM every 2 – 3 years to ensure data retention. In case of any hardware failures, consult the manufacturer’s documentation or a qualified technician for proper troubleshooting and replacement procedures.

Service and Guarantee Commitment: Although the MVME162 – 012 is in a legacy state, Emerson (as the successor to Motorola’s industrial automation business) may still offer limited support. Some refurbished units may come with a short – term warranty, typically covering defects in the processor, memory, and major components. For extended support, customers can explore third – party service providers that specialize in legacy industrial hardware. These providers can offer services such as hardware repair, firmware updates (if available), and technical support. Emerson may also maintain a limited stock of spare parts for critical components of the MVME162 – 012, ensuring that existing systems can be kept operational for as long as possible.