Description

Detailed Parameter Table

| Parameter name | Parameter value |

| Product model | Motorola MVME147-013 |

| Manufacturer | Motorola (now part of Emerson Industrial Automation) |

| Product category | Legacy Industrial VMEbus Analog/Digital I/O Expansion Module |

| Analog Input Channels | 16 differential analog input channels; 12-bit resolution; Input range: ±5V, ±10V, 0–5V, 0–10V (software-configurable per channel) |

| Analog Output Channels | 4 analog output channels; 12-bit resolution; Output range: ±5V, ±10V, 0–5V, 0–10V (software-configurable per channel) |

| Digital I/O Channels | 16 digital input channels (TTL-compatible); 16 digital output channels (TTL-compatible, open-collector); All digital channels with optical isolation (2500V AC rms) |

| Communication Interface | 32-bit VMEbus slave (IEEE 1014-1987 compliant, A16/D16); Interrupt-driven data transfer; Supports VMEbus interrupt levels 1–7 (software-configurable) |

| Calibration | On-board precision voltage reference (±0.1% accuracy); Software-calibratable for offset/gain errors; Temperature drift: <50 ppm/°C |

| Power Requirements | Input voltage: +5V DC (±5%), ±15V DC (±10%); Power consumption: Typical 8 W (25°C, all channels active); Maximum 12 W (max load on analog outputs) |

| Environmental Ratings | Operating temperature: 0°C–55°C (32°F–131°F); Storage temperature: -40°C–85°C (-40°F–185°F); Humidity: 5%–95% (non-condensing); Vibration: 10–2000 Hz, 1.5 g (rms); Shock: 40 g (peak, 1 ms); EMC Compliance: EN 61000-6-2 (industrial immunity) |

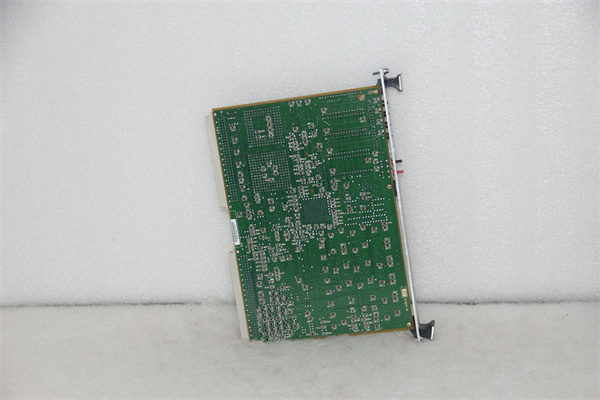

| Physical Dimensions | Single-high 3U VME form factor: 100mm × 160mm × 22mm (3.94in × 6.30in × 0.87in); Weight: 380 g (0.84 lbs) |

| Diagnostic Features | LED indicators (power, VMEbus status, analog input overload, digital I/O activity); Channel-level fault detection (overvoltage, short-circuit for analog outputs); Power-on self-test (POST) for calibration verification |

| Compatible SBCs | Motorola MVME162-012, Motorola MVME162-512A, Motorola MVME167-33A, Motorola MVME187, Motorola MVME2604 |

| Product Life Cycle | Discontinued/Obsolete |

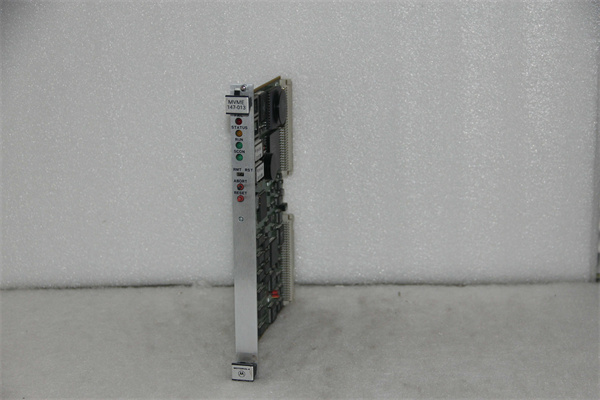

MOTOROLA MVME147-013

Product Introduction

The Motorola MVME147-013 is a legacy industrial VMEbus analog/digital I/O expansion module engineered to extend the connectivity of MVME-series single-board computers (SBCs) like Motorola MVME162-012. Unlike generic I/O modules, Motorola MVME147-013 offers a balanced mix of 16 analog inputs, 4 analog outputs, and 32 isolated digital I/O channels—filling the gap for 1990s industrial systems that need to connect multiple sensors/actuators without replacing their core SBC.

As a dedicated I/O hub in Motorola’s VME lineup, Motorola MVME147-013 acts as a “sensor-to-SBC bridge.” It converts analog sensor signals (e.g., temperature, pressure) into digital data for SBC processing and translates SBC commands into analog/digital signals to control actuators. For example, in a 1990s chemical plant, Motorola MVME147-013 paired with Motorola MVME162-012 to monitor 12 tank level sensors (via analog inputs) and control 8 chemical dosing pumps (via digital outputs)—its optical isolation preventing electrical noise from corrupting data. Today, Motorola MVME147-013 remains critical for legacy systems where upgrading to modern I/O modules would require rewriting SBC firmware or reconfiguring wiring.

Core Advantages and Technical Highlights

Dual Analog/Digital I/O for Mixed-Signal Systems: Motorola MVME147-013’s combination of 16 analog inputs, 4 analog outputs, and 32 digital I/O eliminates the need for multiple single-function modules. A 1990s automotive assembly plant used Motorola MVME147-013 with Motorola MVME167-33A to control a welding station: analog inputs monitored weld temperature/current, analog outputs adjusted power levels, and digital outputs activated clamp actuators. This integration reduced VME chassis slot usage by 60% vs. using separate analog and digital modules, simplifying wiring and cutting hardware costs by 40%.

Optical Isolation for Noise Immunity: All digital channels and analog circuits feature 2500V AC optical isolation—critical for harsh industrial environments with electrical noise. A 1990s steel mill used Motorola MVME147-013 to connect temperature sensors near 480V rolling mills: isolation prevented ground loops and electrical interference from causing false sensor readings (which would have led to overheating steel batches). Non-isolated I/O modules failed within 2 months in this environment, while Motorola MVME147-013 operated reliably for 7+ years.

High Precision + Software Calibration: With 12-bit resolution, ±0.1% reference accuracy, and software calibration, Motorola MVME147-013 delivers precise measurements for critical applications. A 1990s pharmaceutical lab used Motorola MVME147-013 with Motorola MVME187 to monitor drug mixing ratios: analog inputs measured ingredient flow rates with <0.5% error, and software calibration corrected for temperature drift (ensuring compliance with FDA standards). This precision avoided costly batch rejects—something lower-resolution modules (8-bit) couldn’t achieve.

Typical Application Scenarios

In a 1990s municipal water treatment plant, Motorola MVME147-013 served as the primary I/O module for a Motorola MVME162-012 controller. It used 10 analog inputs to monitor pH levels, turbidity, and flow rates in 5 treatment tanks, 2 analog outputs to adjust chemical injector speeds, and 16 digital outputs to control valve actuators. The optical isolation protected against electrical noise from pump motors, while 12-bit resolution ensured accurate pH measurements (critical for meeting EPA water quality standards). Motorola MVME147-013’s 0°C–55°C operating range withstood the plant’s unheated control room (winter lows of 5°C, summer highs of 50°C), and its interrupt-driven transfer ensured real-time alerts for abnormal turbidity levels.

For a 1990s packaging machine in a food processing plant, Motorola MVME147-013 paired with Motorola MVME2604 to automate carton filling. It used 8 digital inputs to detect carton presence/position, 4 analog inputs to monitor fill levels (via load cells), and 12 digital outputs to control conveyor belts, fill valves, and sealers. The module’s software-configurable analog ranges let the plant switch between liquid (0–5V load cell signals) and dry (0–10V) products without hardware changes. Motorola MVME147-013’s POST also simplified troubleshooting—if a digital output failed, the module’s LED indicated the fault, reducing repair time from 4 hours to 30 minutes.

Related Model Recommendations

Motorola MVME162-012: Core SBC – Primary pairing for Motorola MVME147-013; The I/O module extends the SBC’s connectivity for mixed-signal control (e.g., chemical plant tank monitoring).

Motorola MVME147-014: High-precision variant – Upgrade for Motorola MVME147-013 users needing 16-bit analog resolution (e.g., pharmaceutical lab ingredient mixing).

Motorola MVME148-001: Digital-only I/O module – Alternative for Motorola MVME147-013 users with no analog needs (e.g., assembly line actuator control) to reduce costs.

Motorola MVME149-002: Analog-only module – Complement to Motorola MVME147-013 for users needing extra analog channels (e.g., steel mill temperature monitoring).

Emerson MVME147-013-R: Refurbished variant – Tested to original isolation/precision specs; Critical replacement for failing Motorola MVME147-013 units in legacy systems.

Motorola 01-W3960B/61C: Industrial PSU – Powers Motorola MVME147-013 and paired SBCs, ensuring stable +5V/±15V for analog/digital circuits.

Motorola MVME341A: Serial module – Pairs with Motorola MVME147-013 to add remote serial connectivity for I/O data logging (e.g., water treatment plant reports).

Motorola MVME167-33A: Mid-tier SBC – Alternative pairing for Motorola MVME147-013 in high-performance systems (e.g., automotive welding stations).

MOTOROLA MVME147-013

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing Motorola MVME147-013, verify the VME chassis supports 3U modules and provides ±15V DC (required for analog circuits) in addition to +5V. Confirm compatibility with the paired SBC (e.g., Motorola MVME162-012) via VMEbus A16/D16 addressing. Gather tools: anti-static wristband, torque screwdriver (0.3 N·m for 3U mounting), multimeter (to test input voltages), and shielded cables for analog inputs (max length 10m). For digital I/O, use twisted-pair cables; for analog inputs, use differential wiring to minimize noise. Label channels clearly to avoid misconnecting sensors/actuators.

Maintenance suggestions: For daily upkeep, check Motorola MVME147-013’s LEDs—steady power, no overload lights, and active I/O indicators mean normal operation. Run POST monthly to verify calibration and isolation; perform software calibration quarterly (using the paired SBC) to correct drift. Clean vents every 3 months with compressed air (15 PSI max) to prevent dust buildup. If an analog channel shows drift beyond ±0.5%, recalibrate via software; if a digital channel fails, check isolation fuses (replace with 1A fast-blow fuses if needed). Store spare Motorola MVME147-013 units in anti-static bags (15°C–25°C, 40%–60% humidity) to protect precision components.

Service and Guarantee Commitment

Motorola MVME147-013 refurbished units are backed by a 24-month warranty from Emerson, covering defects in analog/digital circuits, isolation components, calibration references, and VMEbus interface. If Motorola MVME147-013 fails (e.g., in a chemical plant), Emerson provides free 7-day expedited replacement—critical for minimizing downtime that costs \(5,000–\)15,000 per day for process-critical systems.

For extended support, customers can purchase a 36-month service contract, including 24/7 technical support (via phone/email, with I/O module specialists), access to archived calibration software and wiring diagrams, and remote troubleshooting for analog drift or digital isolation issues. Emerson maintains a global stock of precision voltage references, optical isolators, and 12-bit ADC/DAC chips for Motorola MVME147-013 until 2040, ensuring legacy mixed-signal industrial systems remain operational. This commitment underscores Emerson’s dedication to supporting the critical I/O infrastructure of industrial automation.