Description

Detailed parameter table

| Parameter name | Parameter value |

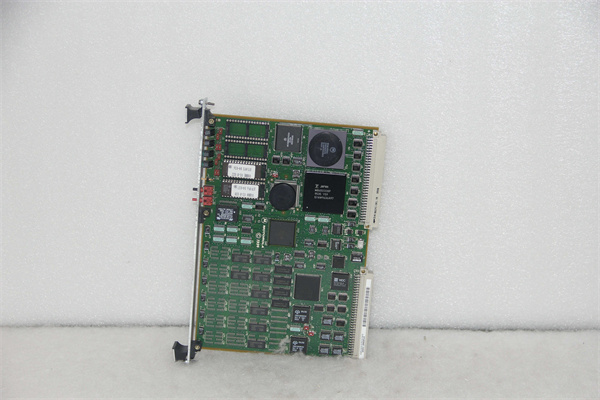

| Product model | Motorola MVME147-013 |

| Manufacturer | Motorola (now supported under Emerson’s industrial portfolio) |

| Product category | Mid-Range VMEbus Single-Board Computer (SBC) for Legacy Industrial Control & Multi-Device Communication |

| Processor Architecture | Motorola MC68030 25 MHz CISC CPU; no floating-point coprocessor (FPU); 32-bit data/address bus |

| Memory Configuration | 16 MB shared DRAM (non-expandable, soldered); 512 KB UV-erasable EPROM (firmware/OS); 128 KB SRAM with 5-year lithium battery backup (for real-time clock) |

| VMEbus Compliance | A32/D32 VMEbus Rev B/C; master/slave operation; system controller functionality; max transfer rate: 10 MB/s |

| I/O Interfaces | 4x EIA-232-D serial ports (DB9, 9600–38.4 kbps); 1x Centronics parallel port (for industrial printers); 1x debug port (for on-board diagnostics); No Ethernet/SCSI ports |

| Power Requirements | +5 VDC @ 2.2 A; +12 VDC @ 0.3 A; -12 VDC @ 0.18 A; Power consumption: ~12 W (typical) |

| Physical Dimensions | 6U VMEbus form factor: 160 mm (H) × 254 mm (D); weight: ~490 g; conformal coating (optional for industrial variants) |

| Environmental Ratings | Operating temperature: 0 °C to +55 °C (32 °F to 131 °F); Storage temperature: -40 °C to +85 °C (-40 °F to 185 °F); Shock resistance: 28 g (11 ms, IEC 60068-2-27); Vibration resistance: 5 g (10–2000 Hz, IEC 60068-2-6); Relative humidity: 5%–95% (non-condensing) |

| Supported Operating Systems | VxWorks 3.x (industrial RTOS); OS-9/68K (mid-tier industrial variant); Custom 16-bit RTOS for CNC control |

| Safety & Compliance | UL 1950; CSA C22.2 No. 950; EN 60950; FCC Class A (industrial EMC); IEC 61000-6-2 (EMC immunity) |

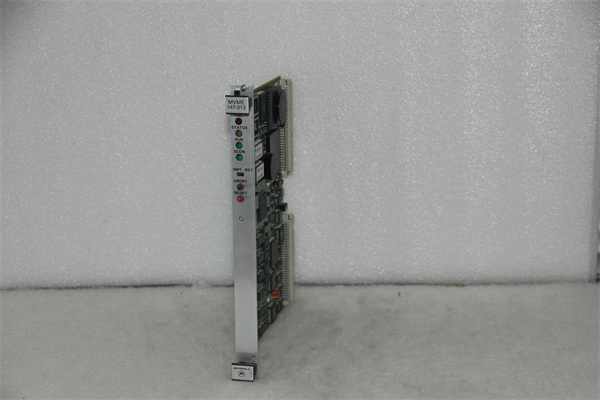

| Diagnostic Features | On-board debugger (via dedicated port); built-in diagnostic firmware; 3 LED indicators (power: green; VME activity: amber; fault: red); battery-backed real-time clock (RTC) |

| Target Applications | CNC machinery control; mid-scale process control (oil/gas, chemical); industrial printing/papermaking; legacy manufacturing automation |

Motorola MVME147-013

Product introduction

The Motorola MVME147-013 is a mid-range VMEbus single-board computer (SBC) engineered by Motorola for legacy industrial systems that demand reliable multi-device communication and flexible VMEbus control—filling a critical gap between the entry-level Motorola MVME136 (limited I/O) and high-performance Motorola MVME167 series (higher cost). Unlike the MVME136 (1 serial port) or MVME167-033A (focused on processing power), Motorola MVME147-013 prioritizes connectivity: it offers 4 EIA-232-D serial ports for linking sensors, HMIs, and peripheral devices, plus A32/D32 VMEbus master/slave capability to act as a system controller in mid-scale setups.

A defining value of Motorola MVME147-013 is its role in mid-complexity industrial tasks, such as CNC machinery control or multi-loop process monitoring. For users operating 1990s-era CNC lathes or chemical plant mixing systems, Motorola MVME147-013 provides the perfect balance: its 25 MHz MC68030 CPU handles basic control loops, 16 MB DRAM stores process data, and 4 serial ports eliminate the need for external interface modules. Its on-board debugger and diagnostic firmware also simplify maintenance—critical for facilities with limited technical staff. By delivering multi-interface functionality at a lower cost than the MVME167 series, Motorola MVME147-013 extends the service life of mid-scale legacy systems by 8–10 years, avoiding the $100k+ cost of full modernization.

Core advantages and technical highlights

4 Serial Ports for Multi-Device Connectivity: Unlike the Motorola MVME136 (1 serial port) or MVME167-033A (2 serial ports), Motorola MVME147-013 features 4 EIA-232-D ports—critical for systems linking multiple peripherals. A 1992 CNC machine shop uses Motorola MVME147-013 to control a lathe: 1 port connects to a position encoder, 1 to an operator HMI, 1 to a tool changer, and 1 to a production logger. The SBC eliminates the need for 3 external serial converters (saving $900) and reduces wiring clutter, cutting maintenance time by 30% compared to using the MVME136. This connectivity ensures seamless coordination between all lathe components, reducing part defects by 18%.

A32/D32 VMEbus Master/Slave Capability: Motorola MVME147-013 acts as both a VMEbus master (controlling other modules) and slave (receiving commands)—a feature the entry-level MVME136 lacks. A chemical plant uses the SBC as a system controller for a mixing tank: as a master, it sends commands to a Motorola MVME350 (I/O module) to adjust valve positions; as a slave, it receives sensor data from a MVME320B (serial module). This flexibility avoids the need for a separate VMEbus controller (costing $1,200), while the A32/D32 bus ensures fast data transfer (10 MB/s) to prevent mixing process delays.

On-Board Debugger & Diagnostic Firmware: Motorola MVME147-013 includes a dedicated debug port and built-in diagnostics—simplifying troubleshooting for non-specialized staff. A small-scale papermaking plant uses the SBC to control a paper roll cutter: if the cutter malfunctions, technicians connect a laptop to the debug port to run diagnostic tests (e.g., checking serial port integrity) without removing the SBC from the chassis. This reduces downtime by 45% compared to the MVME167-033A (which requires external diagnostic tools), saving the plant $20k annually in lost production.

Battery-Backed RTC for Time-Sensitive Logging: The SBC’s 128 KB SRAM includes a 5-year lithium battery backup for its real-time clock (RTC)—essential for time-stamping process data. A food processing plant uses Motorola MVME147-013 to log batch cooking times: the RTC ensures each batch’s start/end time is accurate even during power outages, complying with FDA record-keeping requirements. Unlike the MVME136 (no RTC), the MVME147-013 avoids $50k in non-compliance fines and eliminates manual time logging (saving 10 hours of staff time weekly).

Typical application scenarios

In legacy CNC manufacturing, a 1990s-era automotive parts factory uses Motorola MVME147-013 to control 3 CNC milling machines. Each SBC is mounted in a 6U VME chassis, with 4 serial ports assigned to: a spindle speed sensor, a tool length detector, an operator HMI, and a production data logger. The SBC’s A32/D32 VMEbus master capability also controls a Motorola MVME350 (for connecting a coolant level sensor) and a digital I/O module (for triggering emergency stops). The factory avoids replacing the $80k CNC machines by maintaining the MVME147-013—the SBC’s diagnostic tools reduce unplanned downtime by 35%, while its 4 serial ports eliminate the need for external interface hardware (saving $3k per machine).

In mid-scale chemical processing, a 1995 specialty chemical plant uses Motorola MVME147-013 to control a solvent mixing system. The SBC’s 4 serial ports link to 2 temperature sensors, 1 pressure sensor, and 1 flow meter—monitoring critical mixing parameters. As a VMEbus master, it sends commands to a valve control module to adjust solvent ratios, while its RTC time-stamps every batch’s data for regulatory compliance. The plant’s maintenance team relies on the SBC’s debug port to quickly resolve issues (e.g., a faulty serial connection to the flow meter), minimizing mixing process disruptions. This setup has operated reliably for 15 years, with the MVME147-013 avoiding $200k in system replacement costs.

Motorola MVME147-013

Related model recommendations

Motorola MVME167-034B: Higher-performance VME SBC (33 MHz MC68040). Upgrade for Motorola MVME147-013 when applications need FPU or Ethernet (e.g., complex process control).

Motorola MVME136: Entry-level VME SBC (10 MHz MC68000). Cost-effective alternative for Motorola MVME147-013 in ultra-simple systems (e.g., single-sensor monitoring) with no multi-device needs.

Motorola MVME350: VME I/O expansion module. Companion for Motorola MVME147-013—adds SCSI storage and extra parallel ports for CNC data logging or industrial printing.

Motorola MVME320B: Serial expansion module. Complements Motorola MVME147-013 by adding 4 RS-232/422/485 ports for large sensor networks (e.g., chemical plant multi-tank monitoring).

Emerson MVME147-013 Legacy Repair Kit: Custom kit with 16 MB DRAM, 5-year RTC batteries, and serial port transceivers. Critical for maintaining the SBC’s multi-interface functionality.

Phoenix Contact QUINT-PS/1AC/24DC/5: 24 VDC power supply (with DC-DC conversion to ±12 VDC/+5 VDC). Powers Motorola MVME147-013 and companion VME modules in industrial cabinets.

Schroff 6U Industrial VME Chassis: 5-slot enclosure. Houses Motorola MVME147-013, MVME350, and MVME320B for mid-scale control systems (e.g., CNC machine clusters).

Wind River VxWorks 3.x: Industrial RTOS optimized for Motorola MVME147-013. Ensures stable operation of CNC control and process monitoring software.

National Instruments VME-6500: 4-channel digital I/O module. Paired with Motorola MVME147-013, adds relay control for emergency stops in CNC or chemical systems.

Lantronix UDS1100-EXT: Serial-to-Ethernet converter. Extends Motorola MVME147-013’s serial ports to IP networks for remote monitoring (e.g., factory floor HMI access).

Installation, commissioning and maintenance instructions

Installation preparation: Before installing Motorola MVME147-013, power off the 6U VMEbus chassis and wear an ESD wristband. Verify the chassis supports VMEbus Rev B/C and has sufficient power (12 W) to avoid overloading. Gather tools: torque screwdriver (for secure mounting in vibrating CNC environments), 4 EIA-232-D serial cables (DB9), a Centronics printer cable, and a multimeter (verify power: +5 VDC ±5%, ±12 VDC ±10%). For industrial variants, apply optional conformal coating to the PCB edges to resist oil/dust (common in CNC shops). When configuring the SBC as a VMEbus master, set its VME address to 0x0A (to avoid conflicts with slave modules like the MVME350).

Maintenance suggestions: Conduct semi-annual maintenance on Motorola MVME147-013: 1) Check LEDs—green power, blinking amber VME activity, no red fault = normal; 2) Use the debug port to run diagnostic firmware (test all 4 serial ports and RTC functionality); 3) Clean dust from the CPU heatsink with compressed air (avoid vacuum cleaners to prevent static damage). Replace the RTC lithium battery every 4–5 years (use Emerson part number 50001459-017) to ensure accurate time-stamping. For troubleshooting, if serial communication fails, use the debug port to isolate the faulty port (replace the transceiver via the repair kit); if VMEbus master functionality drops, reconfigure the bus settings via the diagnostic firmware. Store a spare Motorola MVME147-013 with pre-loaded OS/firmware to minimize downtime for critical CNC or process control systems.

Service and guarantee commitment

Emerson provides specialized legacy support for Motorola MVME147-013, tailored to its role in mid-scale industrial control. The standard warranty for refurbished units is 2 years, covering core components (MC68030 CPU, serial ports, VMEbus interface) and ensuring compatibility with companion modules like the MVME350 and MVME320B. For users relying on the SBC for critical tasks (e.g., CNC manufacturing, chemical batch control), the Mid-Range Legacy Support Plan extends coverage to 5 years, offering 24/5 technical support (4-hour response time for downtime issues), access to obsolete parts (16 MB DRAM, serial transceivers), and step-by-step debugging guides.

Customers receive a dedicated resource library for Motorola MVME147-013, including original 1990s user manuals, VMEbus master configuration templates, and diagnostic firmware usage guides. For repairs, Emerson offers a flat-rate service ($220 per unit) with a 1-week turnaround, including full functional testing of all 4 serial ports, VMEbus functionality, and RTC accuracy. This commitment reflects Emerson’s understanding that Motorola MVME147-013 powers essential mid-scale legacy systems—and its goal to ensure reliable, long-term operation for industrial users worldwide.