Description

Detailed parameter table

| Parameter name | Parameter value |

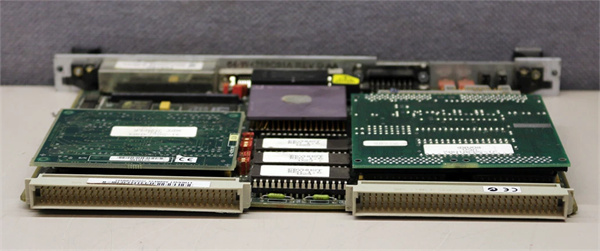

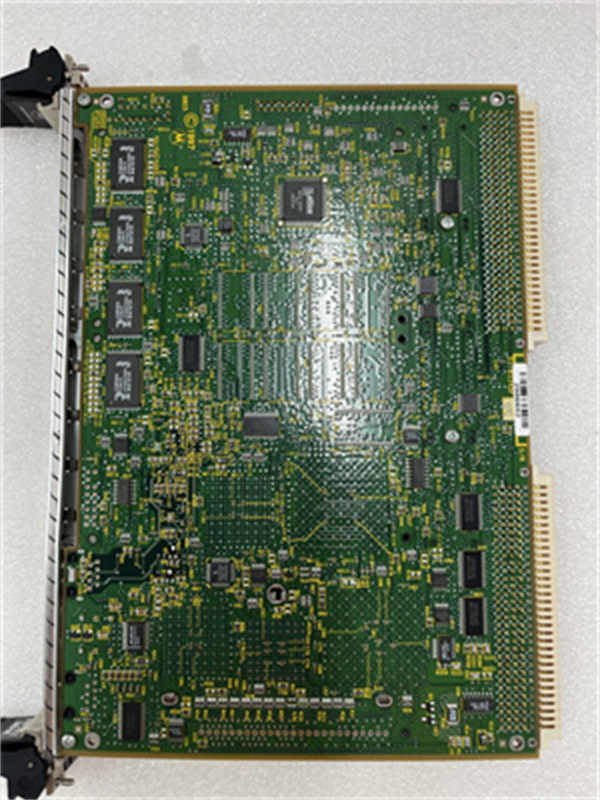

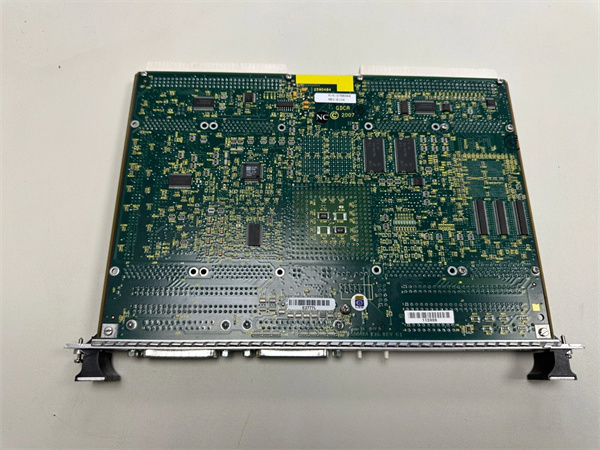

| Product model | MVME-707 |

| Manufacturer | Motorola |

| Product category | Single-slot Hot-swappable CompactPCI/VMEbus SBC |

| Processor | PowerPC™ Series Microprocessor |

| Memory configuration | 280KB Application Runtime, 630KB Nonvolatile Memory |

| Input power | 89-280 VAC |

| Human-machine interface | 12 Function Keys (F1-F10), Touchscreen (180 Touch Cells) |

| Touchscreen durability | 1.5 Million Presses |

| Display resolution | 120×350 Pixels |

| Form factor | Single-slot Eurocard (3U VME Standard) |

| Installation feature | Hot-swappable |

| Bus compatibility | VMEbus (Backward Compatible with ANSI/IEC Standards) |

| Operating temperature range | -25°C to +125°C |

Motorola MVME162PA-344E

Product introduction

The **Motorola MVME-707** is a specialized single-slot hot-swappable CompactPCI/VMEbus Single-Board Computer (SBC) powered by a PowerPC™ Series Microprocessor, tailored for mission-critical industrial automation and human-machine interface (HMI) applications. As a key member of Motorola’s renowned MVME product line, the **Motorola MVME-707** integrates processing capabilities with intuitive user interaction features, making it a versatile solution for systems requiring both computational efficiency and operator control.

With 280KB of application runtime memory and 630KB of nonvolatile memory, the **Motorola MVME-707** ensures reliable storage and execution of control programs, even in power-interrupted scenarios. Its unique combination of 12 function keys and a durable touchscreen (supporting 1.5 million presses) enables seamless operator input, while the 120×350 pixel display delivers clear visual feedback. Designed for industrial ruggedness, the **Motorola MVME-707** operates across an extreme temperature range, making it suitable for harsh environments where standard computing devices fail.

Core advantages and technical highlights

Hot-swappable reliability: The **Motorola MVME-707** features single-slot hot-swappable design, allowing replacement or maintenance without shutting down the entire system. This minimizes downtime in critical applications like power generation or manufacturing, where continuous operation is paramount. The hot-swappable capability also simplifies system upgrades, reducing operational disruptions.

Extreme environmental resilience: Operating from -25°C to +125°C, the **Motorola MVME-707** outperforms standard industrial SBCs in temperature tolerance. This resilience makes it ideal for deployment in outdoor installations, high-temperature industrial processes, or cold-storage facilities, ensuring stable performance regardless of ambient conditions.

Integrated HMI functionality: Unlike many specialized SBCs, the **Motorola MVME-707** combines processing power with built-in HMI components—12 function keys and a rugged touchscreen. This integration eliminates the need for separate HMI modules, reducing system complexity, cabling, and overall costs while improving response times between operator input and system feedback.

Flexible power and bus compatibility: Supporting 89-280 VAC input, the **Motorola MVME-707** adapts to global power standards, simplifying international deployments. Its compliance with VMEbus standards (per ANSI/IEC specifications) ensures backward compatibility with existing VME-based systems, allowing easy integration into legacy setups without costly overhauls.

Typical application scenarios

In oil and gas exploration, the **Motorola MVME-707** serves as a control and monitoring unit for downhole equipment. Its extreme temperature tolerance (-25°C to +125°C) withstands the harsh conditions of drilling rigs and wellhead installations, while the integrated HMI allows on-site operators to adjust parameters and monitor sensor data in real time. The hot-swappable design ensures that maintenance can be performed during active drilling operations, avoiding costly downtime.

Within industrial manufacturing, the **Motorola MVME-707** is deployed as a machine-level controller for high-temperature processes such as metal casting or glass production. It manages heating elements, conveyor systems, and quality sensors, with the touchscreen providing operators with visual alerts for process deviations. The nonvolatile memory preserves critical process data during power fluctuations, ensuring consistent product quality even in unstable electrical environments.

In transportation infrastructure, the **Motorola MVME-707** is used in railway signaling systems and highway toll plazas. Its wide voltage input (89-280 VAC) accommodates varying power supplies in remote locations, while the rugged HMI enables technicians to configure and troubleshoot equipment on-site. The VMEbus compatibility allows it to integrate with existing communication networks, ensuring seamless data exchange with central control centers.

Motorola MVME162PA-344E

Related model recommendations

Motorola MVME-712M: Communication expansion module for MVME-707, adding serial ports and Profibus/Modbus support to enhance network connectivity.

Motorola MVME-162: Digital I/O module compatible with MVME-707, expanding sensor and actuator connectivity for complex control systems.

Motorola MVME-374-1: Higher-performance PowerPC SBC in the MVME series, suitable for upgrading MVME-707 systems requiring increased processing power.

Motorola MVME-6100: Next-generation replacement for MVME-707, featuring enhanced memory, faster processor, and modernized HMI capabilities.

Motorola MVME-2100: Compact MVME SBC complementary to MVME-707, ideal for space-constrained applications where basic processing and HMI are needed.

GE VMIVME-7700: Compatible VMEbus SBC with Intel Celeron processor, offering alternative processing architecture for MVME-707-based systems.

Motorola MVME-197LE: Memory expansion module for MVME-707, increasing DRAM capacity to support more complex control algorithms.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the **Motorola MVME-707**, verify that the VMEbus chassis is powered off and properly grounded. Ensure the input power supply matches the 89-280 VAC requirement and that the chassis slot supports hot-swappable modules. Use ESD-protective equipment to handle the board, avoiding contact with edge connectors. Align the **Motorola MVME-707** with the chassis guides, firmly seat it in the slot until the locking mechanism engages, and confirm proper connection via the chassis backplane.

Maintenance suggestions: Conduct quarterly inspections of the **Motorola MVME-707** to check for loose connections or dust accumulation—use compressed air to clean vents and connectors. Test the touchscreen responsiveness monthly and calibrate using manufacturer tools if input accuracy declines. Back up nonvolatile memory contents regularly to preserve application data. When performing hot-swap replacement, ensure the system is in “maintenance mode” to prevent data corruption. Use only genuine Motorola spare parts to maintain compatibility and environmental resilience.

Service and guarantee commitment

The **Motorola MVME-707** is backed by a 2-year manufacturer’s warranty covering defects in materials and workmanship under normal industrial use. Motorola provides dedicated technical support via email and phone, with response times within 24 hours for critical issues. Our engineers offer on-site commissioning assistance for complex installations, ensuring optimal integration of the **Motorola MVME-707** into your system. For legacy systems, we provide repair and component replacement services to extend product lifecycle. We stand behind the reliability of the **Motorola MVME-707**, offering customized support plans to meet your operational needs and protect your automation investment.