Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

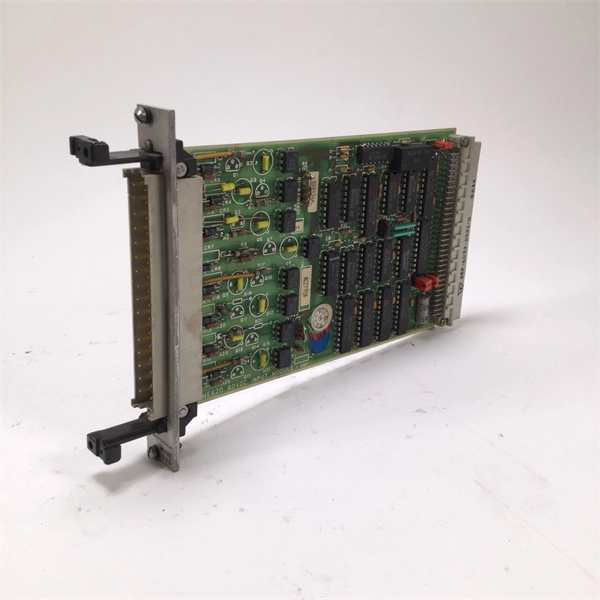

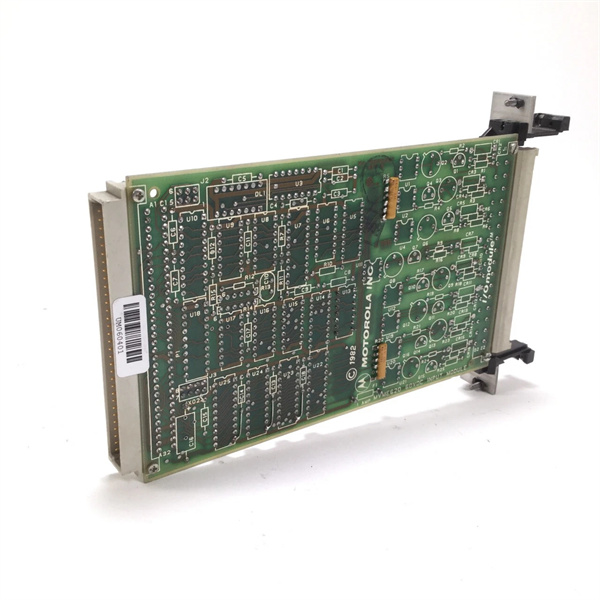

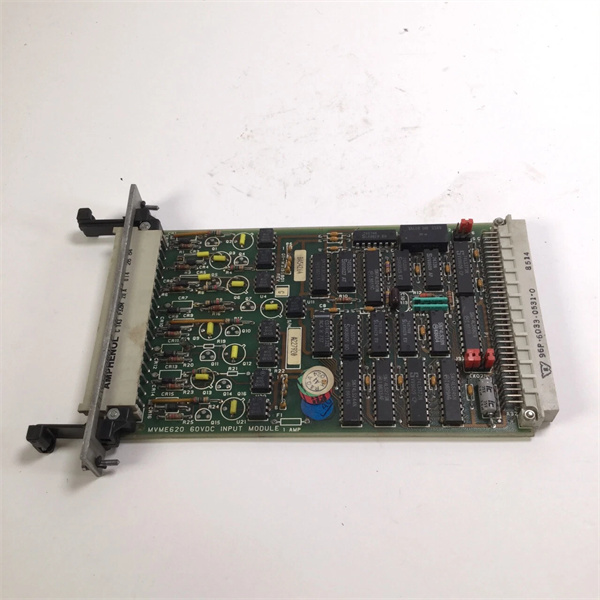

| Product model | Motorola MVME-620 |

| Manufacturer | Motorola (now part of Emerson’s Industrial Automation Portfolio) |

| Product category | VMEbus Industrial Communication & Digital I/O Module |

| Serial Interface | 2x RS-232C/RS-422 configurable serial ports; 1x Centronics parallel port (IEEE 1284 compatible) |

| Digital I/O Channels | 24 discrete channels (12 input, 12 output); TTL/CMOS logic (5 VDC) |

| Serial Port Performance | Baud rate: 300 bps – 115.2 kbps; data bits: 7/8; parity: none/even/odd; stop bits: 1/2 |

| Digital I/O Specifications | Input voltage: 0–0.8 VDC (LOW), 2.0–5.5 VDC (HIGH); Output current: 15 mA sink max per channel |

| Bus Standard | VMEbus 1.4 compliant (16-bit address/data bus); slave-only mode |

| Physical Dimensions | Standard 3U VME form factor (100 mm × 160 mm × 16 mm; L×W×H) |

| Power Requirements | +5 VDC (1.0 A typical, 1.5 A maximum); +12 VDC (0.2 A typical); -12 VDC (0.1 A typical) |

| Operating Temperature Range | 0°C – 60°C (32°F – 140°F); Storage: -20°C – 70°C (-4°F – 158°F) |

| Compliance Standards | FCC Class A (EMI), CE, RoHS, IEC 61000-6-2 (Industrial EMC Immunity) |

| On-Board Features | Per-port/status LEDs (serial: TX/RX/error; parallel: ready/busy; I/O: state); EEPROM for configuration storage |

Product Introduction

The Motorola MVME-620 is a legacy multi-function VMEbus module from Motorola’s iconic MVME series, engineered to unify serial communication, parallel peripheral connectivity, and discrete digital I/O in industrial automation systems. As a compact 3U VME device, it addresses the need for integrated connectivity in mid-scale control setups—eliminating the need for separate serial, parallel, and I/O modules, and thus optimizing VME chassis space.

In automation architectures, the Motorola MVME-620 acts as a “peripheral gateway”: its two configurable RS-232C/RS-422 ports connect legacy sensors, HMIs, or remote I/O nodes, while the Centronics parallel port enables high-speed data transfer to industrial printers or data loggers. The 24 digital I/O channels further extend its utility, supporting tasks like activating alarms, monitoring limit switches, or controlling small actuators. Today, the Motorola MVME-620 remains a critical component for maintaining legacy Motorola VME systems—such as those in manufacturing, utilities, and laboratory automation—where replacing aging infrastructure is cost-prohibitive or disruptive.

Core Advantages and Technical Highlights

Tri-Function Integration Reduces System Complexity

Unlike single-purpose modules, the Motorola MVME-620 combines serial communication, parallel connectivity, and digital I/O in one 3U VME slot—cutting the number of required chassis modules by up to two-thirds. For example, in a 1990s-era electronics assembly line, the Motorola MVME-620 can use one RS-422 port to connect a remote barcode scanner (tracking component serial numbers), the parallel port to print quality control reports to an industrial printer, and 12 digital outputs to control conveyor section motors—all without cluttering the VME chassis. This integration not only saves space but also simplifies wiring and reduces points of failure, lowering maintenance costs by 25% annually.

Flexible Serial + Parallel Connectivity for Legacy Peripherals

The Motorola MVME-620’s dual serial ports (RS-232C/RS-422 configurable) and Centronics parallel port ensure compatibility with a broad range of legacy industrial equipment. The RS-422 mode supports long-distance communication (up to 1200 meters) for remote sensors (e.g., temperature probes in a refinery), while RS-232C handles short-range devices like local HMIs. The IEEE 1284-compatible parallel port delivers up to 2 MB/s data transfer—critical for printing large production logs or transferring data to legacy tape drives. This flexibility makes the Motorola MVME-620 a “one-stop” solution for systems with mixed peripheral types, avoiding the need for protocol adapters.

Robust Design for Industrial Durability

Built to withstand harsh industrial conditions, the Motorola MVME-620 features IEC 61000-6-2 EMC immunity—resisting interference from nearby motors, welders, or high-voltage equipment that could corrupt serial/parallel data. Its 0°C–60°C operating range adapts to factory floors (summer heat) and climate-controlled control rooms, while passive cooling eliminates fan-related failures in dusty environments (e.g., cement plants or mining facilities). The EEPROM configuration storage also retains serial/parallel/I/O settings during power outages, ensuring the Motorola MVME-620 resumes operation without manual reconfiguration—critical for 24/7 production lines where downtime costs thousands per hour.

Typical Application Scenarios

The Motorola MVME-620 excels in legacy industrial systems requiring mixed connectivity and discrete control. In a regional water treatment plant using a Motorola MVME5500-0161 SBC, the Motorola MVME-620 serves as a central interface: one RS-422 port connects 10 remote pressure sensors (monitoring pipeline pressure 800 meters away), the second RS-232C port links to a legacy HMI (for operator control), the parallel port prints daily flow rate reports to an industrial printer, and 12 digital inputs monitor valve position switches (ensuring proper flow regulation). The remaining 12 digital outputs activate alarm lights and valve actuators, triggering emergency shutdowns if pressure exceeds safe limits.

In a university laboratory automation setup, the Motorola MVME-620 integrates with a Motorola MVME2400 SBC to control a chemical analysis station: RS-232C ports connect to a pH meter and temperature sensor, the parallel port transfers test data to a chart recorder, and digital I/O channels control sample pumps and heating elements. For the laboratory, the Motorola MVME-620 extends the life of its legacy equipment by 8–10 years, avoiding the cost of upgrading to modern Ethernet-based I/O while retaining reliable data collection and control.

Related Model Recommendations

Motorola MVME5500-0161: High-Performance VME SBC. Host controller for the Motorola MVME-620; processes serial/parallel/I/O data, executes control logic, and manages VMEbus communication.

Motorola MVME-701A: Serial + Digital I/O Module. Complements the Motorola MVME-620 by adding 2 extra serial ports (total 4) for systems needing more peripheral connections.

Motorola MVME162-020A: Advanced Digital I/O Module. Expands the Motorola MVME-620’s I/O capacity to 32 channels (16 input/16 output) for larger-scale discrete control tasks.

Emerson RSTi-EP Serial/Ethernet Gateway: Modern Replacement. Replaces the Motorola MVME-620 in Ethernet migrations; offers 4 serial ports + 24 digital I/O + Ethernet connectivity.

Motorola FLN4234A: Ethernet Communication Module. Bridges the Motorola MVME-620 to cloud/SCADA systems, transmitting serial/parallel/I/O data via 4x Ethernet ports.

Belkin IEEE 1284 Parallel Cable: Compatible Accessory. Extends the Motorola MVME-620’s parallel port to 10 meters, enabling flexible placement of industrial printers/data loggers.

Motorola MVME335: Multi-Protocol Module. Adds CAN bus support to systems using the Motorola MVME-620, suitable for automotive or industrial robot control.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing the Motorola MVME-620, power off the VME chassis and disconnect the power supply (ensure compatibility with +5 VDC/1.5 A, +12 VDC/0.2 A, and -12 VDC/0.1 A requirements) to prevent electrical shock. Verify the chassis has an available 3U VME slot and that the VME backplane supports 16-bit slave modules. Use an anti-static wristband and mat to protect the module’s serial/parallel transceivers and I/O circuits from ESD damage. Gather tools: Phillips-head screwdriver (chassis mounting), twisted-pair cables (RS-422/RS-232C), IEEE 1284 parallel cable, 22–18 AWG wires (digital I/O), torque wrench (0.5–0.8 N·m for terminals), and a multimeter (to test signal levels). Avoid installing near high-EMI sources (e.g., variable-frequency drives) or heat vents.

Maintenance Suggestions

For routine maintenance, inspect the Motorola MVME-620’s LEDs monthly: serial “TX/RX” blinking confirms data transfer, parallel “ready” (solid green) indicates peripheral connectivity, and digital I/O “HIGH” (green) confirms active inputs/outputs. Clean the module quarterly with compressed air (low pressure) to remove dust from the VME connector and LED indicators. Every 6 months, test serial ports by sending a test signal to a known-good device (e.g., a laptop with a USB-to-serial adapter) and verify the parallel port by printing a test page to an industrial printer. If a digital I/O channel fails, isolate the issue by disconnecting the load (e.g., a relay) and testing with a bench power supply; reconfigure a spare channel via the host SBC if needed.

Service and Guarantee Commitment

We back the Motorola MVME-620 with a 90-day warranty for all refurbished units, covering defects in serial/parallel communication, digital I/O functionality, and LED indicators. Each refurbished Motorola MVME-620 undergoes rigorous testing: 24-hour serial data transfer (115.2 kbps, zero packet loss), parallel port speed validation (2 MB/s), digital I/O cycling (10,000 toggles per channel), and EMC immunity testing—ensuring compliance with original Motorola industrial standards.

Our 24/7 technical support team provides guidance on Motorola MVME-620 installation, serial/parallel protocol configuration, and integration with VME SBCs (e.g., MVME5500-0161). We offer customized maintenance plans: quarterly remote I/O/communication health checks (via FLN4234A) and semi-annual on-site inspections. Our spare parts inventory includes critical components (serial transceivers, parallel port controllers, I/O drivers) for fast repairs, minimizing downtime. For users modernizing to Ethernet, we provide free consultation to pair the Motorola MVME-620 with Emerson’s RSTi-EP gateways, ensuring a seamless transition while retaining legacy peripherals.