Description

Detailed Parameter Table

| Parameter name | Parameter value |

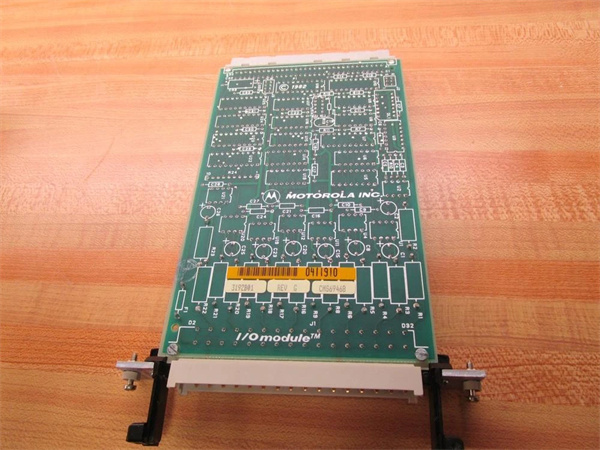

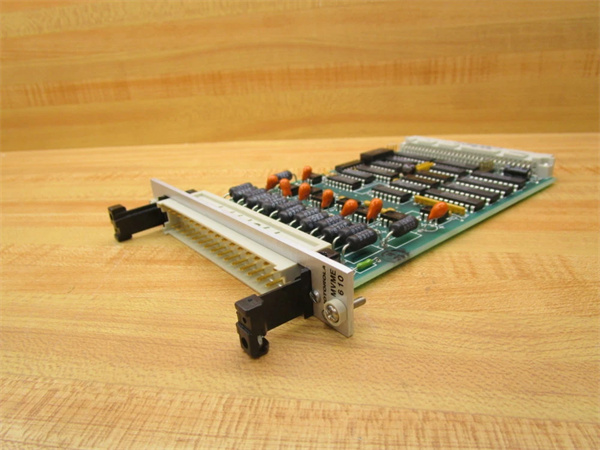

| Product model | Motorola MVME – 610 |

| Manufacturer | Motorola (now part of Emerson Industrial Automation) |

| Product category | Industrial VMEbus – based Computing Module |

| Processor | PowerPC series microprocessor (specific model details vary by source; some suggest a 1.25 GHz PowerPC 604e, while others indicate potential use of other PowerPC variants) |

| Memory Configuration | 295 KB total memory as per some sources; breakdown includes 280 KB application runtime memory and 630 KB non – volatile memory (application objects plus text and bitmaps); other sources mention up to 256 MB SDRAM, indicating possible configuration variability |

| Communication Interfaces | Multiple sources suggest at least 1 Ethernet port; some also mention 2 serial ports and 1 USB port, but this may be model – specific |

| Expansion Interfaces | Likely supports VMEbus expansion, though details on specific expansion slots (such as PMC slots) are not as clear – cut as in more modern models. May have provisions for adding application – specific modules. |

| Environmental Requirements | Operating Temp: Some sources indicate 0 °C – 60 °C; Storage Temp: – 40 °C – 85 °C; humidity and vibration/shock resistance details are less commonly reported but are likely designed to meet general industrial standards |

| Physical Size | Shipping dimensions: 380 x 350 x 20mm; weight: 3.8 lbs (shipping weight); other physical dimensions may vary, with some sources suggesting a more compact form factor compared to larger 6U VME boards |

| Power Consumption | Input power: 89 – 280 VAC; power consumption details at the module level are not as well – defined as in some other products |

| Diagnostic Features | Limited information available, but may have basic LED indicators for power and communication status. Lacks advanced BIST features like more modern models. |

| Compatible Peripherals | Compatible with VMEbus – compliant devices, but specific peripheral models are not as well – documented as in more recent products. May work with standard industrial sensors and actuators through its communication interfaces. |

| Operating Systems | Likely supports real – time operating systems like VxWorks and Linux, though official documentation on supported OS versions is scarce. |

| Product Life Cycle | Discontinued/Obsolete |

Motorola MVME-610

Product Introduction

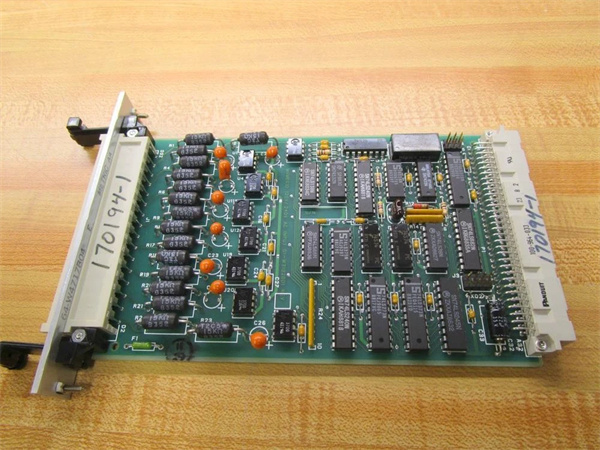

The Motorola MVME – 610 is an industrial VMEbus – based computing module that, while now discontinued, was once a crucial component in a variety of industrial control, communication, and military applications. Positioned as a mid – range solution within Motorola’s product lineup, it offered a balance of processing power and connectivity for its time.

Unlike the more high – end and feature – rich Motorola MVME7100 – 0173, the MVME – 610 was designed to meet the needs of applications that did not require extreme computational resources but still demanded reliable and efficient performance. It served as a building block in systems where tasks such as basic data acquisition, simple control logic execution, and low – to – medium – speed communication were the primary requirements.

In industrial automation setups, the MVME – 610 could be used to control basic conveyor systems, where it would receive input from sensors (connected via its serial or Ethernet ports) to monitor the position of products on the conveyor and control actuators to divert products to the correct bins. Its PowerPC processor, although not as powerful as those in later – generation models, was sufficient for handling these relatively simple tasks in a timely manner.

Core Advantages and Technical Highlights

Decent Processing for Basic Tasks: Depending on the specific PowerPC processor variant, the MVME – 610 could offer a clock speed of up to 1.25 GHz (as per some sources). This processing power was adequate for applications like basic environmental monitoring in industrial plants. For example, it could collect data from multiple temperature and humidity sensors (connected via serial ports) at regular intervals, process the data to check for any out – of – range values, and send alerts if necessary. While it couldn’t handle the high – volume data processing tasks of more advanced models, it was cost – effective for these basic – level operations.

Versatile Communication Interfaces: With at least 1 Ethernet port and potentially 2 serial ports and 1 USB port, the MVME – 610 provided flexibility in connecting to different types of devices. In a small – scale communication network within a factory, it could use its Ethernet port to communicate with a central control station, while the serial ports could be used to interface with legacy devices such as older – generation barcode scanners or simple industrial printers. The USB port, although not as commonly used in industrial settings at the time, could potentially be used for connecting external storage devices for data logging.

Industrial – Grade Design: Built to withstand the rigors of industrial environments, the MVME – 610 had an operating temperature range of 0 °C – 60 °C (as per some sources). This made it suitable for use in factories where temperature fluctuations were common. Additionally, its ability to operate within a wide input power range of 89 – 280 VAC ensured compatibility with different power sources in various industrial locations.

Typical Application Scenarios

In a small – scale food packaging plant, the MVME – 610 could be used to control the packaging machinery. It would receive signals from sensors on the filling machines to monitor the amount of product being filled into each package. Using its processing capabilities, it could calculate if the fill levels were within the acceptable range. If not, it would send control signals to the machinery to adjust the filling process. The Ethernet port could be used to send production data to a central management system for record – keeping and analysis.

For a remote communication relay station in a rural area, the MVME – 610 could be deployed to receive data from multiple sensors in the vicinity (such as weather sensors or traffic sensors) via its serial ports. It would then process this data and use its Ethernet port to forward the aggregated and processed data to a more central location for further analysis. Its ability to operate within a wide temperature range ensured reliable operation even in harsh outdoor conditions.

Motorola MVME-610

Related Model Recommendations

Motorola MVME6100: A more advanced sibling of the MVME – 610. It features a higher – performance PowerPC processor (such as the MPC7457 running at 1.267 GHz), up to 2 GB of onboard DDR ECC memory, and a more advanced cache system (including L1, L2, and L3 caches). Ideal for applications that require more computational power and larger memory capacity, such as complex data – intensive industrial control systems or high – speed data acquisition in aerospace testing.

Motorola MVME – 147 – 011: An entry – level alternative to the MVME – 610. It offers basic processing capabilities and is suitable for very simple applications where cost is a major factor and the processing requirements are minimal, such as controlling a single – axis motor in a basic automation setup.

Emerson – refurbished MVME – 610: For those looking to maintain existing systems using the MVME – 610, refurbished units from Emerson can be a cost – effective option. These units are tested to ensure they meet the original specifications, providing a reliable solution for legacy systems that still rely on this module.

Installation, Commissioning and Maintenance Instructions

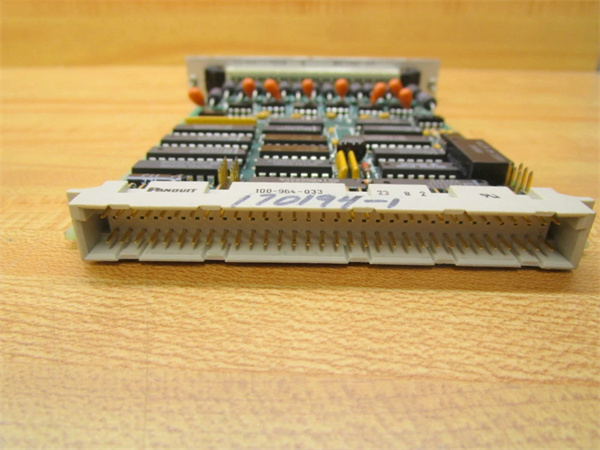

Installation preparation: Before installing the MVME – 610, ensure that the VMEbus chassis is compatible with the module’s form factor and power requirements. Check the power supply to ensure it can provide the required 89 – 280 VAC. Gather necessary tools such as a screwdriver for securing the module in the chassis. If connecting external devices, ensure that the cables for the Ethernet, serial, and USB ports are of the correct type and length.

Maintenance suggestions: Regularly check the LED indicators on the MVME – 610 (if available) to ensure proper power and communication status. Since detailed diagnostic features are limited, periodic testing of the module’s functionality may involve running simple test scripts that check the communication interfaces and basic processing capabilities. If the module is used in a dusty environment, consider cleaning it periodically to prevent dust buildup, which could affect its performance.

Service and Guarantee Commitment

As the MVME – 610 is discontinued, the standard warranty and service options from Motorola are no longer available. However, Emerson (which now owns the Motorola industrial automation product line) may offer limited support for critical applications. This could include providing access to archived technical documentation, refurbished replacement units, and in some cases, limited technical advice for customers still using the MVME – 610 in legacy systems. While not as comprehensive as the support for current – generation products, Emerson’s efforts aim to help customers keep their essential industrial systems operational for as long as possible.