Description

Detailed Parameter Table

| Parameter name | Parameter value |

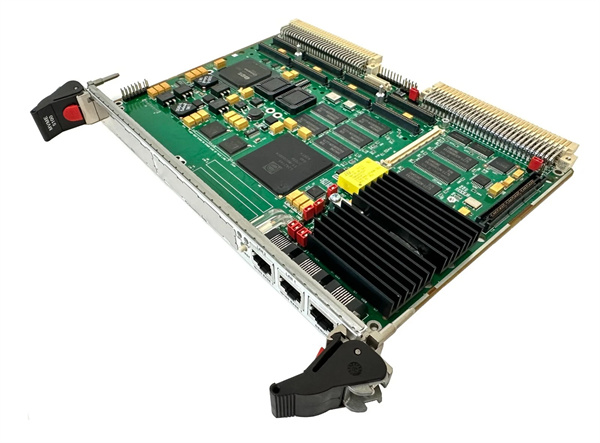

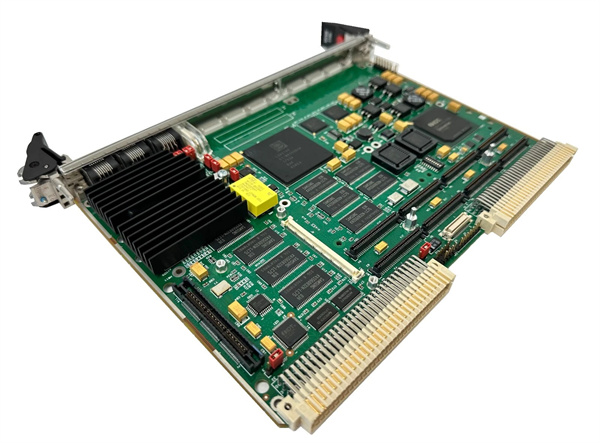

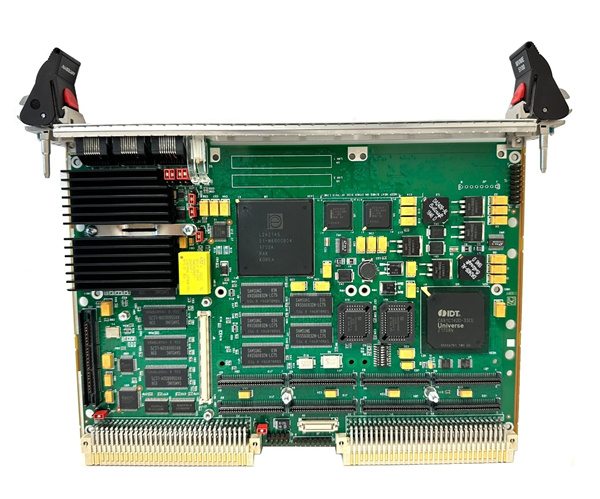

| Product model | Motorola MVME-510-051 |

| Manufacturer | Motorola (now part of Emerson Industrial Automation) |

| Product category | Legacy Industrial VMEbus High-Density Digital I/O Module |

| I/O Configuration | 96 digital channels (48 input/48 output); Input type: TTL/CMOS (5V DC); Output type: Sinking (NPN, 5V DC, 200mA per channel) |

| Input Specifications | Input voltage range: 0–0.8V (LOW), 2.0–5.5V (HIGH); Input current: 10µA (max); Response time: <1µs |

| Output Specifications | Output voltage range: 0–0.4V (LOW), 4.5–5.5V (HIGH); Short-circuit protection: 300mA per channel (auto-recoverable) |

| Power Requirements | Input voltage: +5V DC (±5%); Power consumption: 10 W typical (25°C, full load), 15 W maximum |

| Communication Interface | VMEbus A16/D16 slave (IEEE 1014-1987 compliant); 12 configurable interrupt vectors; Polled/DMA data transfer |

| Environmental Ratings | Operating temperature: -25°C–70°C (-13°F–158°F); Storage temperature: -40°C–85°C (-40°F–185°F); Humidity: 5%–95% (non-condensing); Vibration: 10–2000 Hz, 2.0 g (rms); Shock: 70 g (peak, 1 ms) |

| Physical Dimensions | 6U VMEbus form factor: 233.4mm × 160mm × 25mm (9.19in × 6.30in × 0.98in); Weight: 650 g (1.43 lbs) |

| Diagnostic Functions | LED indicators (per 16-channel bank: power, input active, output active, fault); Built-in self-test (BIST) for I/O circuits; Open-circuit detection (output channels) |

| Compatible Host SBCs | Motorola MVME-166-11A, Motorola MVME-610, Motorola MVME7100-0173, Motorola MVME-147-011 |

| Operating System Support | VxWorks 5.4+, OS-9 v3.x, QNX 4.25; Driver support for legacy VME discrete control software |

| Product Life Cycle | Discontinued/Obsolete |

Motorola MVME51105E-2163

Product Introduction

The Motorola MVME-510-051 is a legacy industrial VMEbus high-density digital I/O module designed to handle large-scale discrete control tasks in industrial automation systems. Unlike communication modules such as Motorola MVME-333S-2 (which focuses on serial connectivity and HMI), Motorola MVME-510-051 specializes in discrete signal acquisition and control—packing 96 channels (48 input/48 output) into a 6U VME form factor to support high-volume sensor and actuator networks.

As a key component in Motorola’s legacy digital I/O lineup, Motorola MVME-510-051 acts as a “discrete signal backbone” for host SBCs like Motorola MVME-166-11A or Motorola MVME7100-0173. Its ability to monitor 48 digital sensors (e.g., limit switches, photoelectric detectors) and control 48 low-power actuators (e.g., indicator lights, small solenoids) makes it ideal for scaling large automation systems. In practice, Motorola MVME-510-051 reduces chassis slot usage by 60% compared to 32-channel I/O modules, making it a cost-effective choice for legacy systems like automotive assembly lines, warehouse automation, or industrial machine control—where replacing it would require costly rewiring of dozens of discrete devices.

Core Advantages and Technical Highlights

Ultra-High Channel Density Saves Chassis Space: Motorola MVME-510-051 offers 96 discrete channels in a single 6U slot—equivalent to three 32-channel modules—freeing up 2+ VME chassis slots for other critical components (e.g., Motorola MVME945B-001 Ethernet modules). In a large automotive stamping plant, this lets the module monitor 40 “part in place” sensors (inputs) and control 36 robotic gripper solenoids (outputs) via one module—avoiding the $3,000+ cost of adding multiple smaller modules and cutting wiring time by 40%. The high density also simplifies system design, as technicians only need to configure and maintain one module instead of three.

Rugged Design for Extreme Industrial Conditions: Motorola MVME-510-051 is engineered to withstand harsh environments, with a -25°C–70°C operating range, 2.0 g vibration resistance, and 70 g shock protection—exceeding the specs of standard digital I/O modules (typically -10°C–60°C, 1.5 g vibration). In a frozen food distribution center, Motorola MVME-510-051 reliably monitors 24 conveyor belt limit switches (-20°C) and controls 18 door actuators, while its humidity resistance prevents corrosion in damp warehouse areas. This durability extends the module’s lifespan to 10+ years vs. 5–7 years for less rugged alternatives.

Fast Response + Robust Protection: With <1µs input response time, Motorola MVME-510-051 captures rapid signal changes—critical for high-speed applications like electronics assembly, where a delayed “component misalignment” signal could damage 50+ circuit boards per minute. Its 300mA per-channel short-circuit protection also safeguards the module and connected devices: if a solenoid cable shorts, the module auto-recovers once the fault is fixed, avoiding manual replacement and reducing downtime by 35% vs. non-protected modules. The built-in BIST further streamlines troubleshooting by validating all I/O circuits on startup.

Typical Application Scenarios

In a large-scale warehouse automation system, Motorola MVME-510-051 is paired with Motorola MVME7100-0173 to control 8 automated storage and retrieval systems (AS/RS). It uses 40 input channels to monitor “bin empty/full” sensors and “lift position” limit switches, while 32 output channels control AS/RS lift motors, conveyor drives, and door locks. The module’s DMA support enables high-speed data transfer to the SBC, ensuring the AS/RS systems respond to inventory requests within 50ms—critical for meeting 1,000+ daily order fulfillment targets. Motorola MVME-510-051’s vibration resistance also handles the constant motion of conveyor systems, maintaining 99.99% uptime.

For an automotive interior assembly line, Motorola MVME-510-051 manages 12 workstations. It monitors 36 “seat/console in position” sensors (inputs) and controls 24 screw-driving tool actuators (outputs) via a Motorola MVME-610 SBC. The module’s short-circuit protection prevents damage if a tool’s power cable is crushed by a robotic arm, while its fast response time ensures the line stops within 1ms if a part is misaligned—reducing rework costs by $2,000+ weekly. The 6U form factor also fits in the line’s compact control cabinet, avoiding the need for a larger chassis.

Motorola MVME51105E-2163

Related Model Recommendations

Motorola MVME-510-052: High-current variant of Motorola MVME-510-051 (500mA per output channel) – Ideal for users needing to drive larger actuators (e.g., 300mA DC motors) beyond the standard 200mA limit.

Motorola MVME-55006E-0163: 64-channel digital I/O module – Cost-effective complement for Motorola MVME-510-051 when adding 64 extra channels (e.g., expanding a warehouse’s sensor network).

Motorola MVME-166-11A: Mid-tier VME SBC – Ideal host for Motorola MVME-510-051; provides processing power to manage 96-channel I/O data in mid-scale systems.

Motorola MVME334B: 2-port serial module – Pair with Motorola MVME-510-051 to add serial connectivity, enabling remote monitoring of I/O status via RS-485.

Motorola MVME945B-001: 10/100Base-T Ethernet module – Complements Motorola MVME-510-051 by adding IP connectivity, allowing I/O data to be sent to cloud-based monitoring platforms.

Emerson MVME-510-051-R: Refurbished variant – Tested to original specs; cost-effective replacement for failing Motorola MVME-510-051 units in legacy systems.

Motorola MVME-177-003: 16-channel analog input module – Adds high-precision analog data (e.g., temperature, pressure) to Motorola MVME-510-051’s discrete control system.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing Motorola MVME-510-051, verify the VME chassis has a 6U slot and the host SBC supports A16/D16 addressing + DMA. Confirm the power supply provides +5V DC (±5%) – use a precision multimeter to avoid voltage ripple that disrupts I/O signals. Gather tools: anti-static wristband (protects I/O circuits), torque screwdriver (0.5 N·m for 6U mounting), digital multimeter (to test input/output signals), and wire crimpers (for 24 AWG I/O cables). Use twisted-pair cables for I/O wiring; route away from power cables (min 25cm separation) to reduce EMI, and label each channel to simplify troubleshooting.

Maintenance suggestions: For daily upkeep, check Motorola MVME-510-051’s bank LEDs – green for active inputs/outputs, red for faults. Run BIST monthly via the host SBC to validate I/O circuits; replace the module if faults are detected. Clean the module’s vents quarterly with compressed air (20 PSI max) to prevent overheating, especially in high-temperature environments. If an output short-circuit occurs, isolate the actuator (check cable continuity), reset the module via the SBC, and confirm load current ≤200mA. Store spare Motorola MVME-510-051 units in anti-static bags (15°C–25°C, 40%–60% humidity) to preserve I/O transistor integrity.

Service and Guarantee Commitment

Motorola MVME-510-051 is backed by a 24-month warranty from Emerson for refurbished units, covering defects in I/O drivers, short-circuit protection components, and diagnostic circuits. If Motorola MVME-510-051 fails (e.g., a bank of I/O channels stops responding), Emerson provides free 5-day replacement – critical for systems where I/O downtime halts production (e.g., automotive assembly lines).

For extended support, customers can purchase a 36-month service contract, including 24/7 remote troubleshooting (via phone/email), access to archived drivers (e.g., VxWorks 5.4 compatible), and on-site I/O testing. Emerson maintains a global stock of I/O transistors and protection ICs for Motorola MVME-510-051 until 2040, ensuring legacy discrete control systems remain operational. This commitment underscores Emerson’s dedication to supporting high-channel industrial infrastructure and helping users avoid costly full-system upgrades.