Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

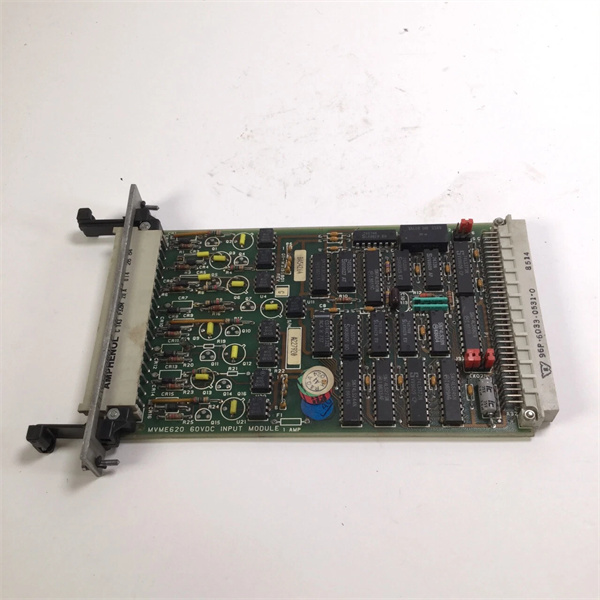

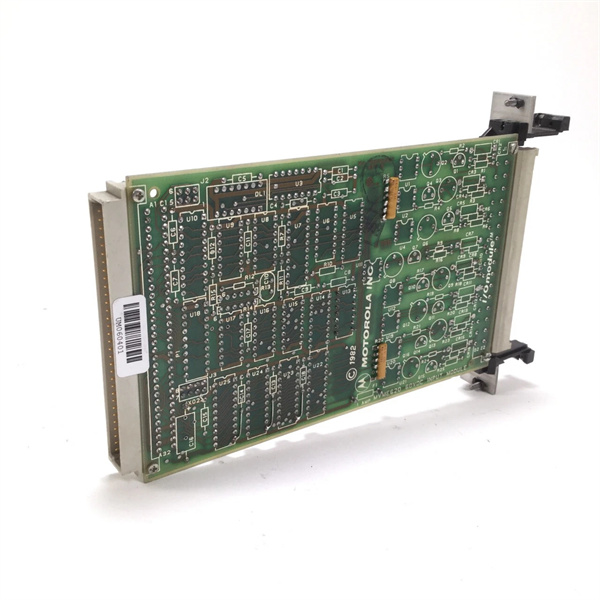

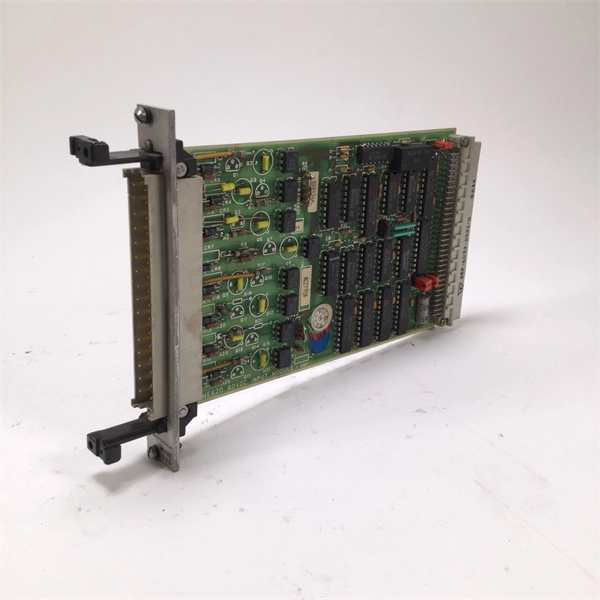

| Product model | Motorola MVME-410 |

| Manufacturer | Motorola (now part of Emerson’s Industrial Automation Portfolio) |

| Product category | VMEbus Industrial Analog I/O & Serial Communication Module |

| Analog I/O Configuration | 8 analog input channels (12-bit ADC); 4 analog output channels (12-bit DAC) |

| Serial Interface | 2x RS-232C serial ports; baud rate: 300 bps – 9600 bps |

| Analog Input Range | Software-selectable: ±5 VDC, ±10 VDC, 0–5 VDC, 0–10 VDC |

| Analog Output Range | Software-selectable: ±5 VDC, ±10 VDC, 0–5 VDC, 0–10 VDC; max current: 10 mA |

| Bus Standard | VMEbus 1.4 compliant (16-bit address/data bus); slave-only mode |

| Physical Dimensions | Standard 3U VME form factor (100 mm × 160 mm × 16 mm; L×W×H) |

| Power Requirements | +5 VDC (1.2 A typical, 1.8 A maximum); ±12 VDC (0.4 A typical each) |

| Operating Temperature Range | 0°C – 60°C (32°F – 140°F); Storage: -20°C – 70°C (-4°F – 158°F) |

| Compliance Standards | FCC Class A (EMI), CE, RoHS, IEC 61000-6-2 (Industrial EMC Immunity) |

| On-Board Features | Per-channel status LEDs (analog: active/fault; serial: TX/RX); EEPROM for calibration storage |

MOTOROLA MVME-605

Product Introduction

The Motorola MVME-410 is a legacy multi-function VMEbus module from Motorola’s iconic MVME series, engineered to integrate analog I/O and serial communication for industrial process control systems. As a compact 3U VME device, it addresses the need for precise analog signal acquisition/control and basic serial connectivity in mid-scale automation setups—eliminating the need for separate analog I/O and serial modules, and thus optimizing VME chassis space.

In process control architectures, the Motorola MVME-410 acts as a “signal interface hub”: its 8 analog inputs capture data from sensors (e.g., temperature, pressure, flow) with 12-bit precision, while 4 analog outputs send control signals to actuators (e.g., valves, pumps). The two RS-232C ports further extend its utility, enabling communication with legacy HMIs or data loggers for local monitoring. Today, the Motorola MVME-410 remains a critical component for maintaining legacy Motorola VME systems—such as those in chemical processing, water treatment, and laboratory automation—where replacing aging analog control infrastructure is cost-prohibitive or disruptive to existing workflows.

Core Advantages and Technical Highlights

Integrated Analog I/O + Serial for Process Control Efficiency

Unlike single-purpose analog modules, the Motorola MVME-410 combines 8 analog inputs, 4 analog outputs, and 2 serial ports in one 3U VME slot—reducing chassis slot usage by 50% compared to using separate analog (e.g., MVME172PA-344E) and serial (e.g., MVME-701A) modules. For example, in a small chemical mixing plant, the Motorola MVME-410 can use 4 analog inputs to monitor pH and temperature sensors, 2 analog outputs to adjust chemical dosing pumps, and 1 RS-232C port to send process data to a local HMI—all without crowding the VME chassis. This integration simplifies wiring and reduces system complexity, lowering installation and maintenance costs by 30%.

Software-Selectable Analog Ranges for Versatility

The Motorola MVME-410’s analog input/output ranges (±5 VDC, ±10 VDC, 0–5 VDC, 0–10 VDC) are software-selectable per channel—eliminating the need for hardware jumpers or range-specific modules. This flexibility is critical for systems with mixed sensor/actuator types: for instance, a water treatment plant can configure 2 analog inputs for 0–10 VDC flow sensors, 2 for ±5 VDC pressure transducers, and 2 analog outputs for 0–5 VDC valve controllers—all on the same module. The 12-bit ADC/DAC precision (0.024% full-scale error) ensures accurate signal capture and control, meeting the needs of most mid-precision process applications.

Robust Design for Industrial Reliability

Built to withstand harsh process control environments, the Motorola MVME-410 features IEC 61000-6-2 EMC immunity—resisting interference from nearby motors, pumps, or high-voltage equipment that could corrupt analog signals. Its ±12 VDC power support (for analog circuits) ensures stable signal conversion, while passive cooling eliminates fan-related failures in dusty settings (e.g., cement plants or mining process control). The EEPROM calibration storage also retains analog range and offset settings during power outages, ensuring the Motorola MVME-410 resumes accurate operation without manual re-calibration—critical for 24/7 process lines where signal drift could cause product defects or safety risks.

Typical Application Scenarios

The Motorola MVME-410 excels in legacy process control systems requiring mid-precision analog I/O and basic serial communication. In a regional wastewater treatment facility using a Motorola MVME5500-0161 SBC, the Motorola MVME-410 serves as a key process interface: 6 analog inputs monitor influent/effluent pH (0–10 VDC), dissolved oxygen (±5 VDC), and flow rate (0–5 VDC) sensors; 3 analog outputs control chemical dosing pumps (0–10 VDC) and a sludge valve (±5 VDC); 1 RS-232C port sends hourly process logs to a legacy data logger. The module’s software-selectable ranges allow the facility to swap sensors without reconfiguring hardware, simplifying maintenance.

In a university laboratory automation setup for material testing, the Motorola MVME-410 integrates with a Motorola MVME2400 SBC to control a temperature chamber: 2 analog inputs measure chamber temperature (0–10 VDC) and pressure (±10 VDC); 2 analog outputs adjust heater power (0–5 VDC) and fan speed (0–10 VDC); 1 RS-232C port connects to a PC for test recipe uploads. For the laboratory, the Motorola MVME-410 extends the life of its legacy equipment by 8–10 years, avoiding the cost of upgrading to modern Ethernet-based analog I/O while retaining reliable process control.

MOTOROLA MVME-605

Related Model Recommendations

Motorola MVME5500-0161: High-Performance VME SBC. Host controller for the Motorola MVME-410; processes analog data, executes PID control logic, and manages VMEbus communication.

Motorola MVME172PA-644SE: High-Precision Analog I/O Module. Upgrade for the Motorola MVME-410 when 22-bit ADC/DAC precision is needed (e.g., pharmaceutical process control).

Motorola MVME-701A: Serial + Digital I/O Module. Complements the Motorola MVME-410 by adding 4 serial ports and 16 digital I/O channels for systems needing more peripheral connectivity.

Emerson RSTi-EP AI/AO Module: Modern Replacement. Replaces the Motorola MVME-410 in Ethernet migrations; offers 16 analog inputs (24-bit) + 8 outputs (16-bit) with Gigabit Ethernet.

Motorola FLN4234A: Ethernet Communication Module. Bridges the Motorola MVME-410 to cloud/SCADA systems, transmitting analog data via 4x Ethernet ports.

Keysight 3458A: Precision Multimeter. Calibration tool for the Motorola MVME-410; provides NIST-traceable voltage references to verify analog accuracy during maintenance.

Motorola MVME-620: Serial + Parallel + Digital I/O Module. Adds parallel printing and 24 digital I/O channels to systems using the Motorola MVME-410, ideal for process lines needing discrete control.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing the Motorola MVME-410, power off the VME chassis and disconnect the power supply (ensure compatibility with +5 VDC/1.8 A, +12 VDC/0.4 A, and -12 VDC/0.4 A requirements) to prevent electrical shock. Verify the chassis has an available 3U VME slot and that the VME backplane supports 16-bit slave modules. Use an anti-static wristband and mat to protect the module’s analog circuits and serial transceivers from ESD damage. Gather tools: Phillips-head screwdriver (chassis mounting), twisted-pair cables (analog sensors), RS-232C cables, torque wrench (0.5–0.8 N·m for terminals), and a precision multimeter (±0.001 V accuracy for calibration). Avoid installing near high-EMI sources (e.g., variable-frequency drives) or heat vents to prevent analog signal drift.

Maintenance Suggestions

For routine maintenance, inspect the Motorola MVME-410’s LEDs monthly: analog “active” (green) confirms signal acquisition, while serial “TX/RX” (blinking) indicates data transfer. Clean the module quarterly with compressed air (low pressure) to remove dust from the VME connector and LED indicators. Every 6 months, calibrate analog channels using a NIST-traceable voltage source: adjust offsets via the host SBC’s software and save settings to EEPROM. If an analog channel fails, isolate the issue by testing with a known-good sensor; if a serial port malfunctions, reconfigure a spare port via software. Replace the module’s internal fuses (1 A slow-blow for ±12 VDC circuits) if power-related faults occur.

Service and Guarantee Commitment

We back the Motorola MVME-410 with a 90-day warranty for all refurbished units, covering defects in analog I/O accuracy, serial communication, and LED indicators. Each refurbished Motorola MVME-410 undergoes rigorous testing: 24-hour analog signal capture (verifying 12-bit precision), serial data transfer (9600 bps, zero packet loss), and temperature cycling (0°C–60°C to confirm stability)—ensuring compliance with original Motorola industrial standards.

Our 24/7 technical support team provides guidance on Motorola MVME-410 installation, analog calibration, and integration with VME SBCs (e.g., MVME5500-0161). We offer customized maintenance plans: quarterly remote analog accuracy checks (via FLN4234A) and semi-annual on-site calibrations. Our spare parts inventory includes critical components (ADC/DAC chips, serial transceivers) for fast repairs, minimizing downtime. For users modernizing to Ethernet, we provide free consultation to pair the Motorola MVME-410 with Emerson’s RSTi-EP AI/AO modules, ensuring a seamless transition while retaining legacy sensors/actuators.