Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

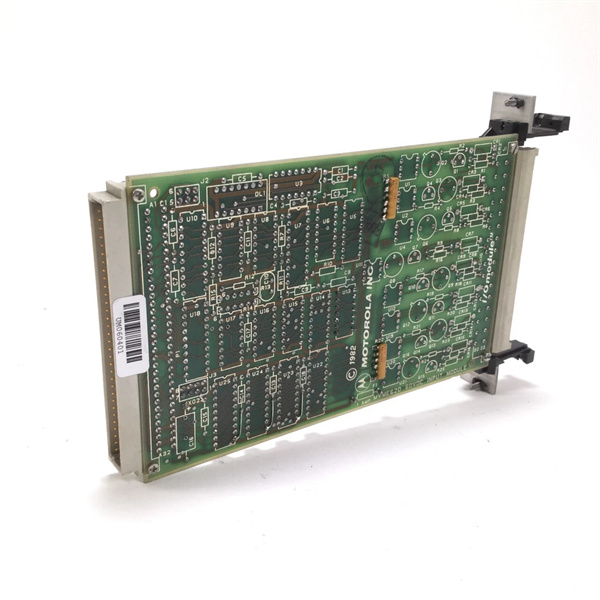

| Product Model | MVME-376 |

| Manufacturer | Motorola |

| Product Category | 3U VMEbus High-Density Digital I/O Module |

| Digital Input Channels | 32 Channels (Optically Isolated) |

| Digital Output Channels | 32 Channels (Relay Output) |

| Input Voltage Range | 24V DC (18-30V DC) |

| Output Relay Rating | 2A @ 250V AC / 3A @ 30V DC |

| Isolation Voltage | 2500V AC (Input to Backplane) |

| VMEbus Interface | VMEchip1 Controller (Slave, 16/32-bit Data Bus) |

| Form Factor | 3U Eurocard (Single-slot VME Standard) |

| Operating Temperature Range | -40°C to +85°C |

| Power Requirements | 5V DC ±5%, 24V DC ±10% (for Relays) |

| Diagnostic Features | Channel Status LEDs, Relay Fault Detection |

| Response Time | Input: ≤1ms, Output: ≤5ms |

Motorola MVME-620

Product Introduction

The **Motorola MVME-376** is a high-density 3U VMEbus digital I/O module designed for industrial automation systems requiring reliable discrete signal handling. As a key member of Motorola’s MVME300 series, it integrates 32 optically isolated digital input channels and 32 relay output channels, providing a comprehensive solution for connecting sensors, actuators, and other discrete devices in mission-critical applications.

With 24V DC input compatibility and robust relay outputs rated for 2A @ 250V AC / 3A @ 30V DC, the **Motorola MVME-376** accommodates a wide range of industrial devices. Its 2500V AC isolation between inputs and the backplane ensures protection against electrical noise and ground loops, enhancing system reliability. The VMEchip1 interface enables seamless integration into VMEbus-based control systems as a slave device, facilitating real-time data exchange with host CPUs. Designed to operate in -40°C to +85°C environments, this module delivers consistent performance in harsh industrial settings.

Core Advantages & Technical Highlights

High-Density I/O Configuration: Featuring 32 input and 32 output channels in a single 3U VME slot, the **Motorola MVME-376** maximizes discrete I/O density, reducing chassis space requirements and cabling complexity. This high density is ideal for systems with numerous sensors and actuators, lowering overall system deployment costs.

Optical Isolation & Relay Protection: Optically isolated inputs prevent electrical noise from interfering with signal acquisition, while the 2500V AC isolation rating ensures safety and reliability in high-noise industrial environments. Relay outputs offer robust switching capability for inductive and resistive loads, with built-in fault detection to alert users of relay failures.

Industrial-Grade Durability: Operating from -40°C to +85°C, the **Motorola MVME-376** withstands extreme temperatures, vibration, and electromagnetic interference (EMI) common in manufacturing plants, oil refineries, and transportation systems. Its rugged construction and high-quality components ensure long-term stable operation, minimizing unplanned downtime.

Fast Response Times: With input response times of ≤1ms and output response times of ≤5ms, the **Motorola MVME-376** captures and acts on discrete signals in real time—critical for time-sensitive control applications such as machine safety interlocks and production line sequencing.

Easy VMEbus Integration: The VMEchip1 controller supports both 16-bit and 32-bit VMEbus data transfers, ensuring compatibility with legacy and modern VMEbus systems. As a slave device, it responds quickly to host commands, enabling timely I/O updates for control algorithms.

Typical Application Scenarios

Manufacturing Automation: In automotive assembly lines, the **Motorola MVME-376** connects proximity sensors (inputs) that detect part presence and relay outputs that control conveyor motors and solenoid valves. Its high density allows monitoring and control of multiple assembly stations from a single module, while optical isolation ensures reliable operation near welding equipment and other high-noise devices.

Power Distribution Control: In electrical substations, the module monitors circuit breaker status (inputs) and controls switchgear (outputs) via relay contacts. The 2500V AC isolation protects the VMEbus system from high-voltage transients, and the wide operating temperature range allows deployment in outdoor substation cabinets.

Material Handling Systems: In warehouse automation, the **Motorola MVME-376** interfaces with photoelectric sensors (inputs) that track pallet positions and relay outputs that control forklift movement and conveyor direction. Fast response times ensure precise coordination of material flow, while relay fault detection prevents system errors due to failed switching.

Process Control Safety Interlocks: In chemical processing plants, the module monitors safety sensors (e.g., pressure relief valves, door interlocks) as inputs and triggers emergency shutdown systems via relay outputs. Optical isolation prevents false signals from chemical processing equipment, ensuring the safety interlock system operates reliably.

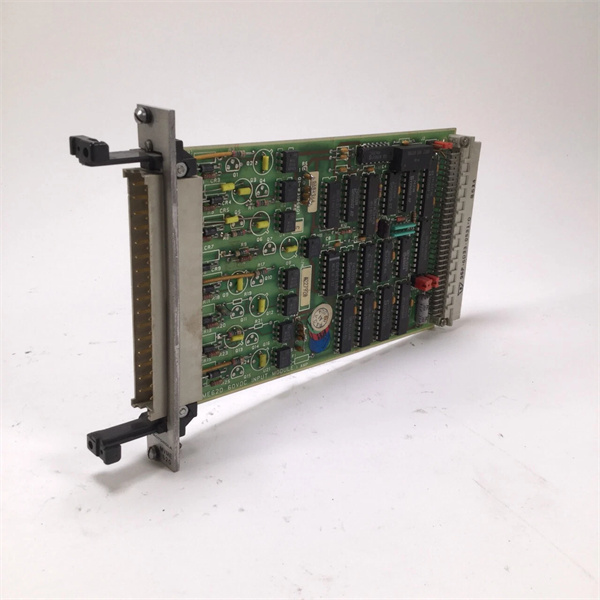

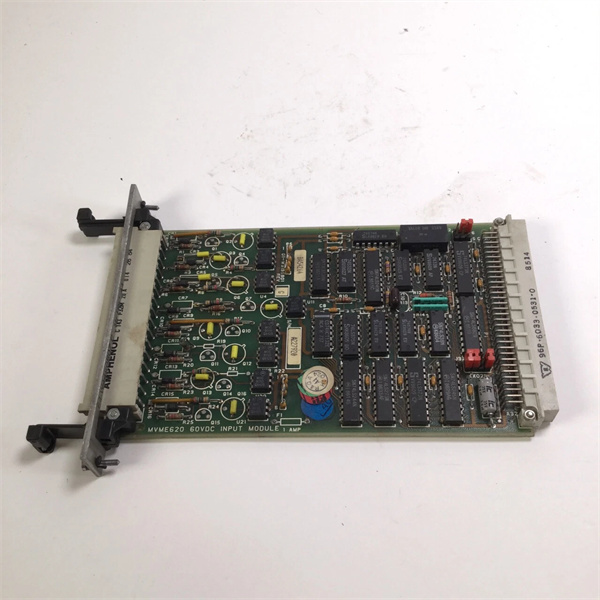

Motorola MVME-620

Related Model Recommendations

Motorola MVME-377: Complementary digital I/O module with 64 input channels, ideal for expanding input capacity alongside **Motorola MVME-376**.

Motorola MVME-162-01: 3U VMEbus CPU module compatible with **Motorola MVME-376**, serving as the host for I/O data processing and control.

Motorola MVME-701A: Serial communication module, working with **Motorola MVME-376** to transmit I/O status data to remote monitoring systems.

GE VMIVME-7650: Analog I/O module complementary to **Motorola MVME-376**, adding analog data acquisition and control capabilities.

Motorola MVME-197LE: Memory expansion module for host CPUs, increasing storage for I/O data logs collected by **Motorola MVME-376**.

Motorola MVME-605: Next-generation PowerPC SBC, pairing with **Motorola MVME-376** for upgraded control systems requiring higher processing power.

Installation & Maintenance Guidelines

Installation Preparation: Before installing the **Motorola MVME-376**, ensure the VMEbus chassis is powered off and properly grounded. Align the module with the 3U slot guides, verifying P1/P2 backplane connector alignment. Gently insert until fully seated, then fasten front-panel screws to prevent vibration-induced disconnections. For wiring, use shielded cables for input channels and ensure proper termination; connect relay outputs to loads within the specified current/voltage ratings.

Maintenance Best Practices: Perform quarterly inspections to clean dust from connectors and front-panel status LEDs using compressed air. Regularly check channel status LEDs to identify faulty inputs or outputs. Test relay outputs monthly by energizing each relay and verifying load operation. Ensure 24V DC power supplies for relays are stable (±10%) to prevent premature relay failure. Use only genuine Motorola spare parts to maintain VMEbus compatibility and I/O performance.

Service & Warranty Commitment

The **Motorola MVME-376** is backed by a 2-year manufacturer’s warranty covering defects in materials and workmanship under normal industrial operation. Motorola’s technical support team provides professional assistance via email and phone, with response times within 24 hours for critical issues. We offer remote diagnostic services to troubleshoot I/O connectivity problems, minimizing on-site service costs. For legacy systems, we provide repair and component replacement services to extend product lifecycle. Our commitment to quality ensures that the **Motorola MVME-376** delivers consistent, reliable digital I/O performance, protecting your investment in industrial automation infrastructure.