Description

Detailed Parameter Table

| Parameter name | Parameter value |

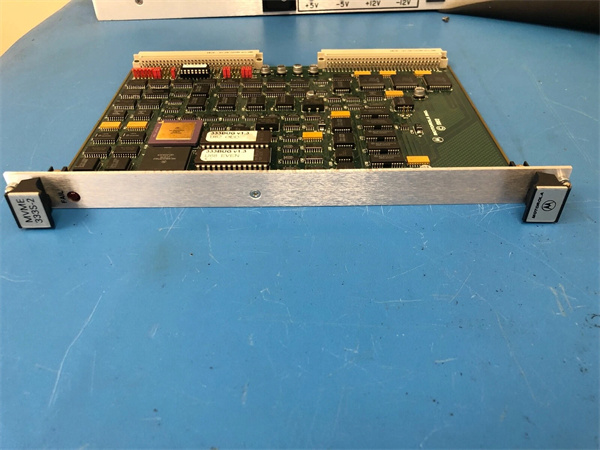

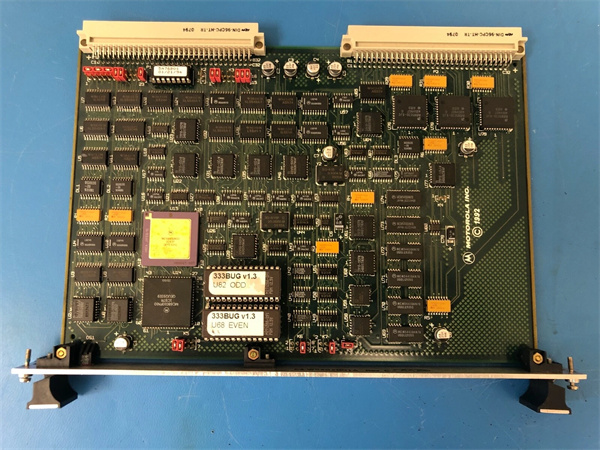

| Product model | Motorola MVME-333S-2 |

| Manufacturer | Motorola (now part of Emerson Industrial Automation) |

| Product category | Legacy Industrial VMEbus Intelligent Serial Communication Controller with HMI |

| Serial Channels | 6 independent RS-232/RS-422/RS-485 ports (software-configurable per channel) |

| HMI Features | 125×55mm green LCD touchscreen (120×350 resolution, 180 touch cells); 12 programmable function keys (F1–F10) |

| Memory Configuration | 295 KB total memory; 280 KB application runtime memory; 630 KB non-volatile memory (for firmware/configuration) |

| Power Requirements | Input voltage: 35–269 V AC (48–67 Hz); Power consumption: 12 W typical (25°C), 18 W maximum |

| Communication Protocols | Modbus RTU, ASCII, RS-232 (DTE/DCE), RS-422 (full-duplex), RS-485 (multi-drop, up to 32 devices) |

| Environmental Ratings | Operating temperature: -10°C–60°C (14°F–140°F); Storage temperature: -40°C–85°C (-40°F–185°F); Humidity: 5%–95% (non-condensing); Vibration: 10–2000 Hz, 1.5 g (rms) |

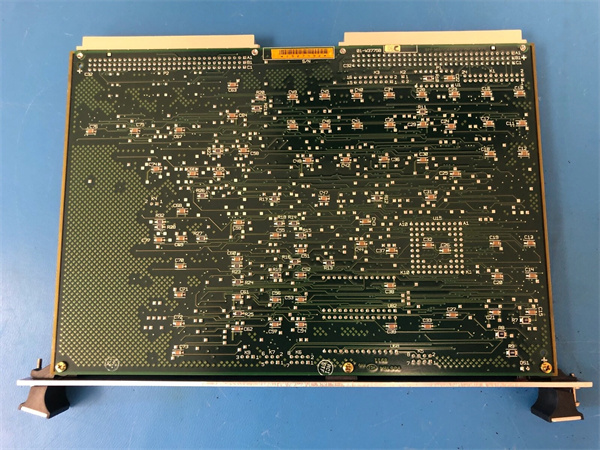

| Physical Dimensions | 3U VMEbus form factor: 100mm × 160mm × 20mm (3.94in × 6.30in × 0.79in); Shipping weight: 3.8 lbs (1.72 kg) |

| VMEbus Compatibility | A16/D16 slave interface (IEEE 1014-1987 compliant); 8 configurable interrupt vectors; Polled/DMA data transfer |

| Diagnostic Functions | LED indicators (power, serial transmit/receive, touchscreen status, fault); Built-in self-test (BIST) for serial ports/HMI |

| Product Life Cycle | Discontinued/Obsolete |

Motorola MVME-333S-2

Product Introduction

The Motorola MVME-333S-2 is a legacy industrial VMEbus intelligent serial communication controller with integrated HMI, designed to serve as a centralized hub for serial device connectivity and local operator interaction in distributed automation systems. Unlike basic serial modules (e.g., 2-port designs), Motorola MVME-333S-2 combines 6 configurable RS-232/RS-422/RS-485 channels with a rugged touchscreen and programmable function keys—eliminating the need for separate communication and HMI modules in space-constrained VME chassis.

As a key component in Motorola’s legacy VME communication lineup, Motorola MVME-333S-2 bridges the gap between host SBCs (e.g., Motorola MVME-166-11A) and field devices like sensors, actuators, and printers. Its ability to handle multi-drop RS-485 networks (up to 32 devices per port) and support industry-standard protocols like Modbus RTU makes it ideal for scaling small-to-medium automation systems. In practice, Motorola MVME-333S-2 acts as both a “communication gateway” (translating data between VMEbus and serial devices) and a “local control panel” (allowing operators to monitor statuses and adjust settings via its touchscreen)—reducing system complexity and improving operational efficiency.

Core Advantages and Technical Highlights

Integrated Communication + HMI Reduces Chassis Clutter: Motorola MVME-333S-2 eliminates the need for separate serial modules and HMIs by combining 6 serial channels with a rugged touchscreen in one 3U slot. For a food processing plant using Motorola MVME-147-011 as the host SBC, this means connecting 4 RS-485 temperature sensor networks and 2 RS-232 printers while using the touchscreen to display real-time batch data—saving $1,200+ in hardware costs and freeing 2 chassis slots for other components (e.g., Motorola MVME-177-003 analog input modules). The 12 programmable function keys further streamline operations, letting operators assign one-touch access to critical tasks like “start batch” or “fault reset.”

Flexible Serial Protocol Support for Legacy Devices: Motorola MVME-333S-2’s 6 channels are individually configurable for RS-232 (DTE/DCE), RS-422 (full-duplex), or RS-485 (multi-drop)—compatible with decades of industrial serial devices. A water treatment plant upgrading from legacy PLCs can use Motorola MVME-333S-2 to connect both old RS-232 pressure gauges and new RS-485 flow meters to a Motorola MVME7100-0173 SBC, avoiding costly device replacements. Its Modbus RTU/ASCII support also ensures seamless integration with SCADA systems, enabling remote monitoring of serial device data without custom software.

Rugged Design for Industrial Reliability: Motorola MVME-333S-2 is built to withstand harsh industrial conditions, with a -10°C–60°C operating range, 1.5 g vibration resistance, and a touchscreen rated for 1.5 million presses. In an automotive assembly line, this durability means Motorola MVME-333S-2 operates reliably near welding robots (electrical noise) and conveyor systems (vibration) while maintaining consistent communication with 12 RS-485-based part sensors. The non-volatile memory also preserves configuration data during power outages, ensuring fast system recovery and minimizing downtime.

Typical Application Scenarios

In a regional water utility’s pump station, Motorola MVME-333S-2 is paired with Motorola MVME-610 to monitor and control 4 remote booster pumps. It uses 4 RS-485 channels to connect to pump controllers (each reporting pressure, flow, and motor temperature) and 2 RS-232 channels to log data to a local printer and communicate with a SCADA radio. The touchscreen displays real-time pump statuses (e.g., “Pump 1: Running, 60 PSI”) and lets on-site technicians adjust setpoints (e.g., “Increase pressure to 65 PSI”) via the programmable function keys.

For a small-scale pharmaceutical packaging line, Motorola MVME-333S-2 connects 3 RS-485 barcode scanners (tracking package IDs) and 1 RS-232 label printer to a Motorola MVME-166-11A SBC. The touchscreen shows batch counts, error logs, and printer status, while operators use the function keys to trigger “print label” or “reject bad package” commands. Motorola MVME-333S-2’s Modbus RTU support also enables the SBC to send batch data to a central MES system, ensuring compliance with FDA 21 CFR Part 11 by maintaining accurate production records.

Motorola MVME-333S-2

Related Model Recommendations

Motorola MVME-333-2: 8-port serial module (no HMI) – Upgrade for users needing more serial channels (8 vs. 6) but no local touchscreen; compatible with the same host SBCs as Motorola MVME-333S-2.

Motorola MVME334B: 2-port serial module – Cost-effective complement for Motorola MVME-333S-2 when adding 1–2 extra RS-232/RS-485 devices (e.g., a secondary printer).

Motorola MVME-166-11A: Mid-tier VME SBC – Ideal host for Motorola MVME-333S-2; provides processing power to manage serial data and HMI commands in mid-scale systems.

Motorola MVME945B-001: 10/100Base-T Ethernet module – Pair with Motorola MVME-333S-2 to add IP connectivity, enabling remote access to serial device data via Ethernet networks.

Motorola MVME-177-003: 16-channel analog input module – Complements Motorola MVME-333S-2 by adding high-precision analog data (e.g., temperature, pressure) to serial-based monitoring systems.

Emerson MVME-333S-2-R: Refurbished variant – Tested to original specs; cost-effective replacement for failing Motorola MVME-333S-2 units in legacy systems.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing Motorola MVME-333S-2, verify the VME chassis has a 3U slot and the host SBC supports A16/D16 addressing. Confirm the power supply provides 35–269 V AC (48–67 Hz) – use a multimeter to check for voltage fluctuations that could damage the touchscreen. Gather tools: anti-static wristband (protects serial/HMI circuits), torque screwdriver (0.3 N·m for mounting), and a serial cable tester (to validate RS-232/RS-485 connections). For RS-485 wiring, add a 120Ω terminator at the farthest device and use shielded twisted-pair cable (24 AWG) to reduce EMI; route serial cables at least 20cm away from power cables.

Maintenance suggestions: For daily upkeep, check Motorola MVME-333S-2’s LEDs – steady power, blinking serial transmit/receive, and no fault lights indicate normal operation. Clean the touchscreen weekly with a lint-free cloth (avoid harsh chemicals) to prevent response issues. Test serial ports monthly by sending a test packet from the host SBC to each connected device; if a port fails, run the built-in BIST to isolate issues (e.g., faulty transceiver vs. cable). Replace the non-volatile memory battery annually (3V lithium) to preserve configuration data. Store spare Motorola MVME-333S-2 units in anti-static bags (15°C–25°C, 40%–60% humidity) to protect the touchscreen and serial components.

Service and Guarantee Commitment

Motorola MVME-333S-2 is backed by an 18-month warranty from Emerson for refurbished units, covering defects in serial transceivers, touchscreen components, and power circuits. If Motorola MVME-333S-2 fails (e.g., unresponsive touchscreen or serial port malfunction), Emerson provides free 7-day replacement – critical for systems where downtime disrupts production or monitoring (e.g., water utility pump stations).

For extended support, customers can purchase a 36-month service contract, including 24/7 remote troubleshooting (via phone/email), access to archived drivers (e.g., VxWorks 5.4 compatible), and on-site assistance for serial network configuration. Emerson maintains a global stock of critical components (serial transceivers, touchscreen controllers) for Motorola MVME-333S-2 until 2038, ensuring legacy systems remain operational. This commitment underscores Emerson’s dedication to supporting industrial infrastructure and helping users avoid costly full-system upgrades.