Description

Detailed Parameter Table

| Parameter name | Parameter value |

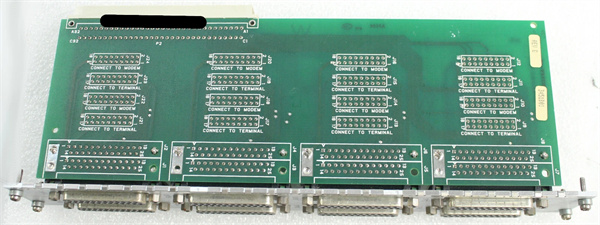

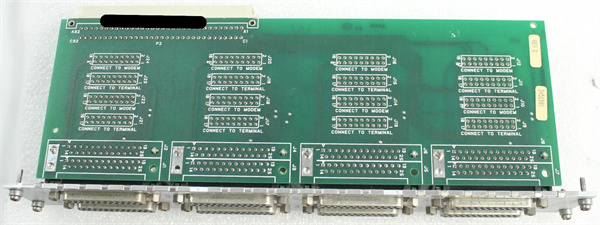

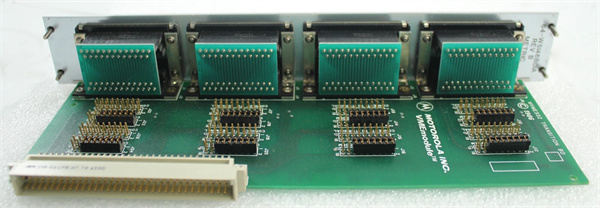

| Product model | Motorola MVME-332 |

| Manufacturer | Motorola (now part of Emerson Industrial Automation) |

| Product category | Legacy Industrial VMEbus High-Density Digital I/O Module |

| I/O Type | 64-channel digital input (DI) + 64-channel digital output (DO) (total 128 channels, configurable via jumpers for 32 DI/96 DO or 96 DI/32 DO) |

| Input Voltage Range | Digital Input: 5V DC (TTL) / 24V DC (industrial standard); compatible with sinking/sourcing inputs |

| Output Voltage Range | Digital Output: 5V DC (TTL, 200 mA max per channel) / 24V DC (industrial standard, 500 mA max per channel); short-circuit protected |

| Isolation | Channel-to-channel isolation: 250V AC (rms); Module-to-backplane isolation: 500V AC (rms); surge protection: 1 kV (transient voltage) |

| Communication Interface | VMEbus P1/P2 connectors (complies with IEEE 1014-1987); supports VMEbus A16/A24 address cycles; interrupt-driven I/O for real-time response |

| Operating Temperature Range | -10°C to 60°C (14°F to 140°F); Storage Temperature Range: -40°C to 85°C (-40°F to 185°F) |

| Humidity Resistance | 5%–95% (non-condensing, 40°C dew point); Vibration Resistance: 10–500 Hz, 1.5 g (rms); Shock Resistance: 50 g (peak, 10 ms duration) |

| Physical Size | 3U VMEbus form factor: 100 mm × 160.02 mm (3.94 in × 6.30 in); Weight: 380 g (0.84 lbs) |

| Power Consumption | Typical: 12 W (25°C, full load, 64 DI/64 DO); Maximum: 18 W (all channels active, 24V DC output) |

| Compatibility | VMEbus SBCs: Motorola MVME-147SB-1, Motorola MVME162-043, Motorola MVME162-222; Operating Systems: OS-9 v1.x/v2.x, VxWorks 5.2+, QNX Neutrino 6.1+ |

| Diagnostic Features | LED indicators (per 8-channel bank: input status, output status, power); Built-in short-circuit detection for outputs; Over-temperature protection (auto-shutdown at 70°C) |

Motorola MVME-332

Product Introduction

The Motorola MVME-332 is a legacy industrial VMEbus high-density digital I/O module from Motorola (now integrated into Emerson’s portfolio), designed to expand the input/output capabilities of MVME series single-board computers (SBCs) like the Motorola MVME-147SB-1 or Motorola MVME162-043. Unlike standalone SBCs, the Motorola MVME-332 focuses exclusively on digital signal management—offering 128 configurable channels (64 DI/64 DO by default) to handle large-scale sensor data acquisition and actuator control in industrial automation systems.

In automation architectures, the Motorola MVME-332 acts as a “high-density I/O hub”: it connects to dozens of digital sensors (e.g., limit switches, photoelectric sensors) and actuators (e.g., solenoid valves, relay coils) via its isolated channels, then communicates with a host SBC (such as the Motorola MVME-147SB-1) over the VMEbus. Its configurable channel split (32/96 or 96/32 DI/DO) adapts to diverse application needs—from monitoring 96 status sensors in a packaging line to controlling 96 small motors in a conveyor system. This makes the Motorola MVME-332 indispensable for mid-to-large-scale legacy systems, such as 1990s-era automotive assembly lines or regional utility control panels, where maximizing I/O density within 3U VMEbus chassis space is critical.

Core Advantages and Technical Highlights

High-Density Configurable I/O for Scalability: The Motorola MVME-332’s 128-channel design (configurable to 32/96 or 96/32 DI/DO) delivers 2x the I/O density of smaller modules like the Motorola MVME-717 (32 channels), reducing the number of VMEbus slots needed in a chassis. For example, a 1995 automotive component assembly line requiring 80 sensors (DI) and 48 actuators (DO) can use one Motorola MVME-332 (configured to 96 DI/32 DO) plus one small DO module—vs. 4–5 smaller I/O modules—freeing up slots for other components like communication gateways. This scalability lowers chassis costs and simplifies wiring by centralizing I/O connections.

Industrial-Grade Isolation and Protection: Unlike consumer-grade I/O modules, the Motorola MVME-332 features 250V AC channel-to-channel isolation and 500V AC module-to-backplane isolation—critical for preventing electrical noise or ground loops from disrupting sensitive SBCs like the Motorola MVME-147SB-1. Its output channels also include short-circuit protection (500 mA max per channel) and over-temperature shutdown, avoiding module damage in harsh environments. For instance, in a steel mill where electrical interference from large motors is common, the Motorola MVME-332’s isolation ensures sensor signals remain accurate, while short-circuit protection prevents burnout if an actuator cable is accidentally grounded.

Real-Time Interrupt-Driven I/O: The Motorola MVME-332 supports VMEbus interrupt-driven I/O, enabling it to send instant alerts to the host SBC when a sensor state changes (e.g., a limit switch triggering) or an output fault occurs (e.g., short circuit). This eliminates the need for the SBC to continuously poll I/O channels—reducing processor load on legacy SBCs like the Motorola MVME-147SB-1 (25 MHz MC68030) and ensuring sub-10 ms response times. For example, in a high-speed bottling line, the module can interrupt the SBC the moment a bottle is detected out of position, allowing the SBC to stop the line within 5 ms—preventing product jams and reducing waste.

Broad Compatibility with Legacy MVME SBCs: The Motorola MVME-332 is fully compatible with all MVME series SBCs, including the Motorola MVME-147SB-1, Motorola MVME162-12, and Motorola MVME162-043, and supports legacy operating systems like OS-9 v1.x/v2.x and VxWorks 5.2+. This means users upgrading their SBC (e.g., replacing a Motorola MVME-147SRF with a Motorola MVME-147SB-1) can retain existing Motorola MVME-332 modules—avoiding the cost of rewriting I/O drivers or replacing wiring. For a food processing plant with a 20-year-old control system, this compatibility extends the life of their I/O infrastructure while improving processing power via a new SBC.

Typical Application Scenarios

In 1990s-era automotive assembly line control, the Motorola MVME-332 is paired with the Motorola MVME-147SB-1 to manage a door panel installation station. Configured to 64 DI/64 DO, the Motorola MVME-332 connects to 48 photoelectric sensors (detecting door panel alignment, fastener presence) and 32 solenoid valves (controlling robotic grippers, fastener drivers). It uses interrupt-driven I/O to alert the Motorola MVME-147SB-1 the moment a sensor detects a misaligned panel, triggering the SBC to pause the robot and send an alert to the operator. The module’s 24V DC output compatibility matches the plant’s existing actuator power system, and its short-circuit protection prevents damage if a gripper cable is crushed—ensuring 99.8% station uptime.

For regional water utility pump control, the Motorola MVME-332 (configured to 96 DI/32 DO) works with the Motorola MVME162-043 to monitor and control 12 water pumps across 5 rural stations. It connects to 80 pressure/temperature sensors (DI) and 12 pump start/stop relays (DO), using its RS-485 integration (via the host SBC) to send data to a central SCADA system. The module’s isolation protects the Motorola MVME162-043 from ground loops between remote pump stations, while over-temperature protection shuts down outputs if a relay overheats—preventing pump burnout. The Motorola MVME-332’s -10°C to 60°C operating range also withstands outdoor enclosure temperatures in winter and summer.

In legacy warehouse conveyor control, the Motorola MVME-332 (configured to 32 DI/96 DO) is used with the Motorola MVME162-222 to manage a 10-zone conveyor system. It connects to 32 limit switches (detecting package presence) and 96 conveyor motor relays (controlling speed and direction), logging sensor data to the SBC’s IDE HDD for maintenance tracking. The module’s interrupt-driven I/O allows the SBC to adjust conveyor speed in real time based on package backlog, reducing energy consumption by 20% vs. constant-speed operation. Its 3U form factor fits the warehouse’s existing VMEbus chassis, avoiding the need for costly infrastructure upgrades.

Motorola MVME-332

Related Model Recommendations

Motorola MVME-147SB-1: Mid-entry legacy SBC paired with the Motorola MVME-332. The SBC provides processing power for I/O control, while the module expands digital I/O capabilities—ideal for small-to-mid-scale assembly lines.

Motorola MVME162-043: Mid-legacy SBC compatible with the Motorola MVME-332. Offers faster 66 MHz 68k processing for complex I/O logic (e.g., pump control with leak detection) and hybrid PMC compatibility.

Motorola MVME-717: 32-channel digital input module complementary to the Motorola MVME-332. Adds extra DI channels for systems needing more sensors than the MVME-332’s maximum 96 DI.

Motorola MVME-712-M: 16-channel digital output module paired with the Motorola MVME-332. Provides high-current (2 A) outputs for large actuators (e.g., heavy-duty motors) beyond the MVME-332’s 500 mA limit.

Motorola MVME-050: Industrial power supply for the Motorola MVME-332 and host SBC. Delivers stable ±5V/±12V/24V DC output to power the module’s 128 channels and SBC components.

Motorola MVME-910-3: Ethernet gateway module for systems using the Motorola MVME-332. Enables the host SBC to send I/O data to modern SCADA systems, bridging legacy VMEbus and IP networks.

Motorola MVME-230: Analog I/O module used with the Motorola MVME-332. Adds temperature/pressure monitoring (analog inputs) to systems primarily using the MVME-332 for digital control.

Motorola MVME-333: High-voltage variant of the Motorola MVME-332. Supports 110V AC I/O for industrial systems using high-voltage actuators (e.g., large valves in power plants).

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing the Motorola MVME-332, verify the VMEbus chassis has an available 3U slot and is compatible with P1/P2 connectors. Confirm the power supply provides 24V DC (for industrial I/O) and ±5V/±12V (for module logic)—use a multimeter to check voltage tolerance within ±5%. Gather tools: anti-static wristband (to protect module circuitry), torque screwdriver (0.35 N·m for chassis mounting), wire strippers/crimpers (for I/O wiring), and a vintage laptop (running OS-9 v2.x/VxWorks 5.2+) for configuration. Set the module’s DI/DO split jumpers (per user manual) before mounting—e.g., 64 DI/64 DO for balanced applications. Power off the chassis, clean the VME backplane connector with a dry soft-bristle brush, then slide the Motorola MVME-332 into the slot until fully seated.

Maintenance suggestions: For daily upkeep, check the Motorola MVME-332’s bank LEDs—green for active inputs/outputs, red for faults (e.g., short circuit). Test 10% of I/O channels weekly via the host SBC (e.g., trigger a test sensor and verify the module sends an interrupt) to ensure real-time response. Clean the module’s exterior every 3 months with compressed air (30 PSI max) to remove dust—critical for preventing overheating in factory environments. Every 6 months, inspect I/O wiring for corrosion or loose connections (common in humid utility enclosures) and replace damaged cables. If the Motorola MVME-332 triggers an over-temperature shutdown, check for blocked air vents or excessive channel load (reduce active outputs if needed) before restarting. Store spare modules in anti-static bags in a climate-controlled environment (15°C–25°C, 40%–60% humidity).

Service and Guarantee Commitment

The Motorola MVME-332, as a legacy industrial I/O module, is backed by an 18-month factory warranty from Emerson—covering defects in materials and workmanship (e.g., isolation failure, output short-circuit protection malfunction, LED indicator errors) in remaining stock units. If a defect is identified during the warranty period, Emerson provides free 5-day replacement for available units—critical for systems where I/O downtime halts production (e.g., automotive assembly lines). For extended support, customers can purchase legacy service contracts (up to 36 months) including access to archived technical documentation (e.g., wiring diagrams, driver installation guides) and limited email support from engineers specializing in VMEbus I/O systems.

Emerson maintains a limited global stock of critical components for the Motorola MVME-332 (e.g., isolation transformers, output driver ICs) to support essential legacy users (e.g., automotive manufacturers, regional utilities) until 2032. Due to the module’s vintage nature, on-site service is available for critical systems (e.g., power grid control) at an additional cost, with engineers providing hands-on troubleshooting for wiring or compatibility issues. This commitment ensures the Motorola MVME-332 remains a reliable I/O expansion solution for legacy MVMEbus systems, helping users avoid costly full-system upgrades.