Description

Detailed Parameter Table

| Parameter name | Parameter value |

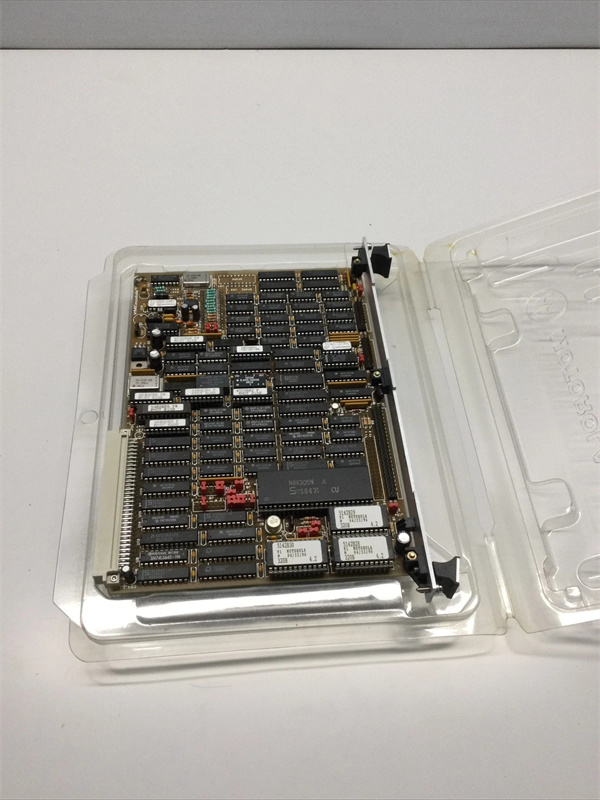

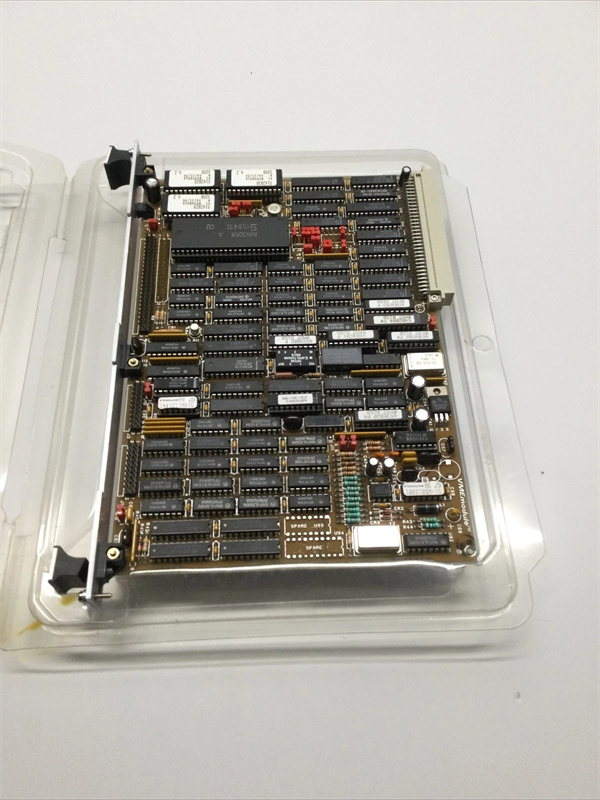

| Product model | Motorola MVME-320 |

| Manufacturer | Motorola (now part of Emerson Industrial Automation) |

| Product category | Legacy VMEbus Intelligent Winchester/Floppy Disk Controller Module; Single-slot VME module |

| Microprocessor | Motorola MC68000 8-bit/16-bit microprocessor (8 MHz clock speed) |

| Input Power | Operating voltage: +5V DC ±5%, +12V DC ±10%; Power consumption: Typical 8W, Maximum 12W |

| Memory | 64 KB SRAM (for runtime data processing); 16 KB EPROM (for firmware storage, non-writable) |

| Disk Drive Support | 1x ST506/ST412-compatible Winchester hard disk (max 20 MB capacity); 1x 5.25″ floppy disk drive (1.2 MB/360 KB format) |

| Communication Interfaces | VMEbus A16/D16 slave interface (for host SBC communication); 1x RS-232 serial port (9600 bps max, for diagnostic/configuration) |

| Environmental Requirements | Operating temp: 0°C to 50°C (32°F to 122°F); Storage temp: -40°C to 85°C (-40°F to 185°F); Humidity: 10%–90% (non-condensing) |

| Physical Size | 3U VMEbus form factor: 100 mm × 160.02 mm (3.94 in × 6.30 in); Weight: 350 g (0.77 lbs) |

| Diagnostic Features | LED indicators (power, hard disk activity, floppy disk activity, fault); Basic self-test (BIST) for disk drive connectivity |

| Product Life Cycle Status | Discontinued/Obsolete |

| Compatible Host SBCs | Motorola MVME-147SRF, Motorola MVME-147SB-1, Motorola MVME162-12 |

| Firmware Support | Motorola Disk Controller Firmware v1.2 (fixed in EPROM, no field updates) |

Motorola MVME320B-1

Product Introduction

The Motorola MVME-320 is a legacy VMEbus Intelligent Winchester/Floppy Disk Controller Module—one of the earliest single-slot disk control solutions in Motorola’s MVME series, designed to enable data storage/retrieval for VME-based industrial systems. As the foundational model of the MVME320 family (which includes upgraded variants like the Motorola MVME320B-1), the Motorola MVME-320 focuses on basic disk management, bridging the gap between host SBCs (e.g., Motorola MVME-147SRF) and legacy storage devices like ST506 hard disks and 5.25″ floppy drives.

In 1980s–1990s industrial automation, the Motorola MVME-320 acted as a “storage gateway”: it received data from host SBCs (e.g., sensor logs from a manufacturing line) via the VMEbus, wrote it to the Winchester hard disk for long-term retention, and loaded firmware/configuration files from floppy drives to the SBC during system startup. Unlike later models like the Motorola MVME320B-1 (which supports multiple drives and higher capacities), the Motorola MVME-320 is optimized for small-scale systems—such as standalone machine control or low-frequency data logging—where basic storage needs take priority over scalability. This makes it a critical legacy component for preserving operation of early VMEbus systems, such as 1990s-era textile looms or vintage water treatment controllers.

Core Advantages and Technical Highlights

MC68000-Based Reliability for Legacy Storage: The Motorola MVME-320 uses an 8 MHz Motorola MC68000 microprocessor—an industry-standard chip for 1980s industrial equipment—known for its stability in harsh environments. Unlike modern processors, the MC68000’s simple architecture minimizes firmware complexity, reducing the risk of crashes in critical storage tasks. For example, in a 1992 food packaging line, the Motorola MVME-320 reliably writes daily production logs (500+ entries/day) to a 20 MB ST506 hard disk, ensuring data integrity even during voltage fluctuations common in factory power grids.

Compact Single-Slot Design for Space-Constrained Chassis: As a 3U VME module, the Motorola MVME-320 occupies only one slot in VMEbus chassis—critical for early industrial systems where space was limited. For instance, a 1989 vintage robotic arm control system (with a 4-slot VME chassis) can fit the Motorola MVME-320 alongside a Motorola MVME-147SRF (SBC) and two I/O modules, leaving no unused slots. This compactness contrasts with bulky external disk controllers of the era, which required separate power supplies and chassis space.

Seamless Compatibility with Early VME SBCs: The Motorola MVME-320’s A16/D16 VMEbus interface is fully compatible with entry-tier legacy SBCs like the Motorola MVME-147SRF and Motorola MVME-147SB-1. It uses a simple command set that works with OS-9 v1.x (the dominant RTOS for 68k-based systems), requiring no custom drivers—critical for users with limited technical expertise. For example, a small manufacturing plant upgrading from a paper-tape storage system can connect the Motorola MVME-320 to their existing Motorola MVME-147SRF and start using floppy drives for firmware loading within hours, no software rewrites needed.

Basic but Robust Diagnostic Tools: The Motorola MVME-320 includes LED indicators for power, disk activity, and faults, plus a basic BIST function that verifies disk drive connectivity during startup. In a 1990s water pump control system, an operator can quickly diagnose issues: a blinking hard disk LED indicates normal data transfer, while a solid fault LED signals a loose disk cable—reducing troubleshooting time from hours to minutes. This simplicity is key for legacy systems where technical documentation is often lost or incomplete.

Typical Application Scenarios

In 1980s–1990s standalone machine control, the Motorola MVME-320 is paired with the Motorola MVME-147SRF to manage a vintage 1991 metal lathe. It stores lathe operation parameters (speed, tool position, material type) on a 20 MB ST506 hard disk, allowing operators to recall 10+ preset configurations for different parts. The 5.25″ floppy drive is used to load firmware updates (e.g., tool path algorithms) from factory-supplied disks. The Motorola MVME-320’s 0°C–50°C operating range withstands the lathe’s workshop environment, and its 8W power consumption fits the machine’s 12V DC supply.

For low-frequency data logging in rural utilities, the Motorola MVME-320 is integrated into a 1993 well water monitoring system. It connects to a Motorola MVME-147SB-1 (SBC) that collects daily water level/pH data (10 entries/day), which the Motorola MVME-320 writes to a 20 MB hard disk—enough for 5+ years of logs. The RS-232 port allows technicians to retrieve data via a laptop (using a 1990s-era terminal program) during quarterly site visits. The module’s fault LED alerts technicians to disk failures, preventing data loss in remote locations where on-site service is infrequent.

In legacy industrial firmware management, the Motorola MVME-320 serves as a “firmware loader” for a 1988 textile loom control system. The loom’s Motorola MVME-162-12 (SBC) lacks built-in storage, so the Motorola MVME-320 loads weaving pattern firmware from 5.25″ floppy disks (1.2 MB each) during startup. The hard disk stores backup patterns (20+ designs), ensuring the loom can resume production quickly if a floppy disk is damaged. The Motorola MVME-320’s EPROM firmware (v1.2) has remained stable for decades, avoiding the need for risky updates to the loom’s aging control software.

Motorola MVME320B-1

Related Model Recommendations

Motorola MVME320B-1: Upgraded variant of the Motorola MVME-320 with MC68020 processor (16 MHz), support for 2x hard disks/2x floppy drives, and expanded memory (295 KB total). Ideal for users scaling from single-drive to multi-drive storage (e.g., mid-sized manufacturing lines).

Motorola MVME-147SRF: Entry-tier legacy SBC fully compatible with the Motorola MVME-320. The SBC provides processing power for industrial tasks, while the MVME-320 handles storage—perfect for standalone machines like vintage lathes.

Motorola MVME-717: 32-channel digital input module paired with the Motorola MVME-320. Collects sensor data (e.g., lathe tool position) for the host SBC, which then stores it on the MVME-320’s hard disk.

Motorola MVME-020: Low-power industrial power supply for the Motorola MVME-320. Delivers stable +5V/+12V output (85–264 VAC input) to power the module and connected disk drives, handling its 12W max load.

Motorola MVME-900-1: Legacy RS-232 adapter for the Motorola MVME-320. Extends the module’s serial port range by 50 meters, enabling remote diagnostic access (e.g., in rural well monitoring systems).

ST506 Hard Disk (20 MB): Vintage hard disk designed for the Motorola MVME-320. Critical for replacing failed drives in legacy systems—modern SSDs require adapters and may not work with the module’s firmware.

5.25″ Floppy Drive (1.2 MB): Compatible floppy drive for the Motorola MVME-320. Used to load firmware/configuration files into host SBCs (e.g., textile loom pattern data).

Motorola MVME-330: VMEbus Ethernet controller for systems using the Motorola MVME-320. Enables the host SBC to send data (stored on the MVME-320) to remote SCADA systems—bridging legacy storage and basic network connectivity.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing the Motorola MVME-320, verify the VMEbus chassis has an available 3U slot and supports A16/D16 addressing (standard for legacy VME systems). Confirm the power supply provides stable +5V DC (±5%) and +12V DC (±10%)—use a multimeter to avoid voltage spikes that could damage the MC68000 processor. Gather tools: anti-static wristband (to protect sensitive components), Phillips screwdriver (0.3 N·m torque for chassis mounting), and a vintage ST506 hard disk/floppy drive (pre-configured for ST506 protocol). Power off the chassis, clean the VME backplane connector with a dry soft-bristle brush, then slide the Motorola MVME-320 into the slot until fully seated (avoid bending pins on the disk drive interface cables).

Maintenance suggestions: For daily upkeep, check the Motorola MVME-320’s LEDs—steady power LED, blinking disk activity LEDs, and no fault LED indicate normal operation. Run BIST monthly by power-cycling the module; a solid fault LED after startup signals a disk drive or cable issue. Clean the module’s air vents (if present) every 3 months with compressed air (20 PSI max) to prevent overheating. Every 6 months, back up hard disk data to a floppy disk (store spares in a dust-free container) —vintage ST506 drives are prone to failure. If the Motorola MVME-320 fails to detect a disk drive, check the interface cable (replace with shielded ST506 cables if damaged) and verify the drive’s jumper settings (set to “Master” for single-drive configurations). Store spare modules in anti-static bags in a climate-controlled environment (15°C–25°C, 40%–60% humidity) to preserve EPROM/firmware integrity.

Service and Guarantee Commitment

The Motorola MVME-320, as a discontinued legacy module, no longer includes a factory warranty. However, specialized third-party service providers (focused on vintage industrial hardware) offer repair services for common issues: MC68000 processor replacement, EPROM firmware restoration, and disk interface repair. These providers often source original components (e.g., 68000 chips, ST506 connectors) to maintain compatibility with legacy systems.

For critical applications (e.g., vintage manufacturing lines with no modern 替代品), legacy support companies offer limited 12-month service contracts for the Motorola MVME-320. These contracts include access to archived documentation (installation manuals, firmware v1.2 guides) and priority repair turnaround (5–7 business days). While the module is obsolete, these services extend its usable life by 5–8 years, helping users avoid the cost of replacing entire VMEbus systems (which can exceed $50,000 for specialized industrial equipment).