Description

Detailed Parameter Table

| Parameter name | Parameter value |

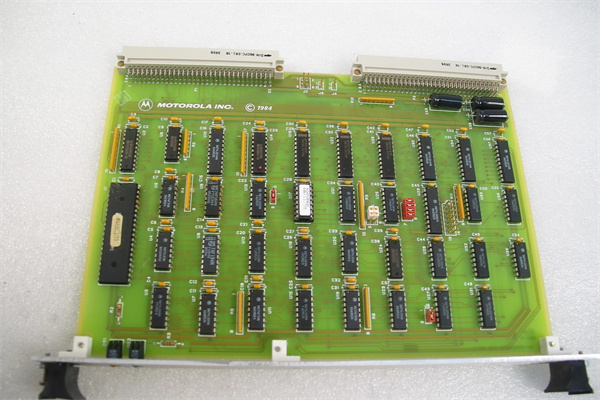

| Product model | Motorola MVME – 316 |

| Manufacturer | Motorola (now part of Emerson Industrial Automation) |

| Product category | Single – slot hot – swappable CompactPCI board with PowerPC™ series microprocessor |

| Microprocessor | PowerPC series (specific model not detailed in common sources, but designed for embedded industrial computing) |

| Input Power | 89 – 280 VAC |

| Memory | 295 KB total; 280 KB for application runtime, 630 KB non – volatile memory (for application objects, text, and bitmaps) |

| Communication Ports | Remote I/O (RIO); RS232 (for printer connection); likely has additional serial or network interfaces for general data transfer in industrial setups |

| Keypad Function Keys | 12 function keys (F1…F10) |

| Touchscreen | Touch cells: 180; Actuation: 1.5 million presses; Resolution: 120 * 350; Display area: 125 x 55 mm (4.54 x 3.4 in.); Display type: Green |

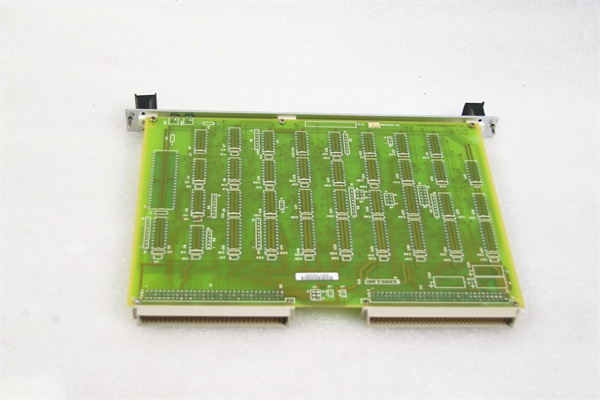

| Physical Size and Weight | Size details not fully clear, but as a single – slot CompactPCI board, it adheres to standard CompactPCI form factors; Weight: 1.8 kg |

| Environmental Requirements | Not comprehensively detailed, but as an industrial – grade module, it is expected to have a reasonable operating temperature range for industrial environments, likely similar to – 20°C to 60°C and humidity tolerance in non – condensing conditions |

| Product Life Cycle Status | Discontinued/Obsolete |

Motorola MVME-316

Product Introduction

The Motorola MVME – 316 is a single – slot, hot – swappable CompactPCI board that was equipped with a PowerPC™ series microprocessor. Designed for industrial embedded computing applications, it was part of Motorola’s lineup of products aimed at providing reliable computing power within the CompactPCI architecture.

During its prime in the industrial computing market, the MVME – 316 was used in a variety of applications where compact form factor, hot – swappable capabilities, and the processing power of the PowerPC series were crucial. It could be integrated into industrial control systems, such as those found in manufacturing plants, transportation infrastructure control centers, or even some military – related embedded computing setups. The hot – swappable feature was a significant advantage, allowing for maintenance and upgrades without shutting down the entire system, minimizing downtime in critical industrial operations.

Core Advantages and Technical Highlights

PowerPC – based Processing Performance: The use of a PowerPC series microprocessor in the MVME – 316 provided a balance of performance and energy efficiency suitable for industrial applications. PowerPC processors were known for their RISC (Reduced Instruction Set Computing) architecture, which allowed for faster processing of instructions compared to some CISC (Complex Instruction Set Computing) processors of the era. This made the MVME – 316 well – equipped to handle tasks such as real – time data processing, control algorithms execution in industrial machinery, and communication protocol handling between different components in a factory automation network.

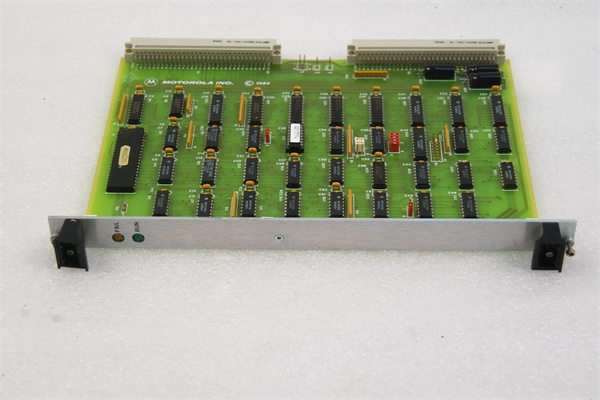

Hot – Swappable CompactPCI Design: As a hot – swappable CompactPCI module, the MVME – 316 offered enhanced system availability. In industrial environments where continuous operation is often a necessity, the ability to replace or upgrade the module while the system is running is invaluable. For example, in a 24/7 manufacturing line, if the MVME – 316 started to show signs of degradation, maintenance personnel could swap it out with a spare module without halting the production process. This not only saved time but also reduced the risk of financial losses associated with production stoppages. The CompactPCI form factor also ensured mechanical stability and compatibility with other CompactPCI – based components in the system, allowing for easy integration into existing industrial control chassis.

Rich I/O and Human – Machine Interface Features: With its 12 function keys and touchscreen capabilities, the MVME – 316 provided a convenient way for operators to interact with industrial systems. The touchscreen, with its 180 touch cells, 1.5 million – press actuation durability, and a resolution of 120 * 350, was suitable for displaying information and receiving input in industrial settings. In a transportation control center, operators could use the touchscreen and function keys to monitor and control traffic signals, access real – time data on vehicle flows, and adjust control parameters. The communication ports, including Remote I/O (RIO) and RS232, enabled seamless integration with other industrial devices such as printers for logging data, and connection to remote sensors or actuators in a distributed industrial control network.

Typical Application Scenarios

Industrial Control in Manufacturing Plants: In a large – scale automotive manufacturing plant, the MVME – 316 could be used in the production line control system. It would receive real – time data from various sensors placed on the assembly line, such as sensors monitoring the position of robotic arms, the quality of welded joints, and the presence of components in the assembly process. The PowerPC processor on the MVME – 316 would process this data, execute control algorithms to adjust the speed and operation of the robotic arms, and communicate with other control modules in the system. The touchscreen and function keys could be used by operators on the factory floor to monitor the production status, access diagnostic information, and make on – the – fly adjustments to the production process.

Transportation Infrastructure Control: In a traffic management system for a major city, the MVME – 316 could play a role in the control center. It would be connected to a network of traffic sensors, cameras, and signal controllers via its communication ports. The module would analyze data on traffic flow, detect traffic jams, and adjust traffic signal timings in real – time. Operators in the control center could use the touchscreen and function keys to view traffic maps, access historical traffic data, and override the automatic control system in case of special events or emergencies. The hot – swappable feature would ensure that any maintenance or upgrade of the MVME – 316 could be done without disrupting the continuous operation of the traffic management system.

Industrial Data Logging and Monitoring in Power Generation: In a power generation plant, the MVME – 316 could be used for data logging and monitoring of various parameters such as temperature, pressure, and voltage. It would collect data from sensors placed throughout the plant, process this data, and store it in its non – volatile memory. The data could then be retrieved and analyzed for equipment maintenance planning, performance optimization, and compliance reporting. The touchscreen could be used to display real – time data trends, alarm status, and historical data for operators to quickly assess the health of the power generation equipment.

Related Model Recommendations

Motorola MVME – 320: As a disk controller module in the same MVME series, the MVME – 320 could be paired with the MVME – 316 in some industrial systems. For example, in a data – intensive industrial control setup, the MVME – 316 could handle the overall system control and data processing, while the MVME – 320 could manage the storage of large amounts of data on Winchester hard disks or floppy drives, ensuring that important operational data and logs are safely stored.

Compatible CompactPCI Chassis: Since the MVME – 316 is a CompactPCI module, it requires a suitable CompactPCI chassis for installation. Chassis models from manufacturers like Advantech or Kontron that support hot – swapping and have sufficient power supply capacity (able to handle the 89 – 280 VAC input of the MVME – 316) would be ideal. These chassis also provide mechanical support and proper grounding for the MVME – 316, ensuring reliable operation in industrial environments.

Industrial – Grade Power Supplies: To ensure stable power supply to the MVME – 316, industrial – grade power supplies that can provide clean and regulated power within the 89 – 280 VAC input range are recommended. Brands such as Mean Well offer a range of power supplies with high efficiency and reliability, which are crucial for the proper functioning of the MVME – 316 in industrial settings where power fluctuations can be common.

Sensors and Actuators: Depending on the application, various sensors and actuators can be connected to the MVME – 316 via its communication ports. For example, in a manufacturing plant, proximity sensors, pressure sensors, and servo – actuators could be connected to the MVME – 316’s Remote I/O (RIO) interface. These sensors and actuators would provide real – time data to the MVME – 316 and receive control signals in return, enabling seamless operation of the industrial process.

Motorola MVME-316

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Before installing the MVME – 316, ensure that the target CompactPCI chassis is powered off and properly grounded. Verify that the chassis has an available single – slot for the MVME – 316 and that it supports the hot – swappable feature. Check the power supply of the chassis to ensure it can provide the required 89 – 280 VAC input for the MVME – 316. Use an anti – static wristband to protect the module from electrostatic discharge during handling. Inspect the MVME – 316 for any visible signs of damage, such as bent pins or cracked components.

Commissioning: Once installed in the chassis, power on the system. The MVME – 316 should be recognized by the system firmware if all connections are correct. Use the appropriate software tools (usually provided by Motorola or the system integrator) to configure the module, such as setting up communication parameters for the RIO and RS232 ports, and initializing the touchscreen and function keys. Calibrate the touchscreen if necessary to ensure accurate user input. Test the module’s functionality by running basic diagnostic programs and checking for proper communication with other components in the system.

Maintenance Suggestions: Regularly check the status of the MVME – 316 through the system monitoring software. Look for any signs of abnormal behavior, such as high processor utilization, communication errors, or unresponsive touchscreen. Clean the module’s surface and ventilation openings (if any) periodically to prevent dust accumulation, which could affect its performance. In case of a hardware failure, if the module is still under warranty (although it is discontinued, some legacy warranties may still apply), contact the relevant support channels. If out of warranty, specialized third – party repair services that deal with vintage industrial hardware can be considered. They may be able to repair components such as the PowerPC processor, replace damaged memory chips, or fix communication port issues. Store spare MVME – 316 modules in a static – free environment, preferably in an anti – static bag, to maintain their integrity for future replacements.

Service and Guarantee Commitment

As a discontinued product, the Motorola MVME – 316 no longer has a standard factory warranty. However, some legacy support programs may still exist, depending on the region and the original purchase agreement. Specialized third – party service providers that focus on vintage industrial hardware can offer repair and maintenance services. These providers often have expertise in sourcing hard – to – find components, such as specific PowerPC processors or CompactPCI – specific connectors, to ensure the continued operation of the MVME – 316.

For critical applications where replacing the MVME – 316 with a modern alternative is not immediately feasible, some legacy support companies may offer extended service contracts. These contracts can include services such as remote diagnostic support, access to archived technical documentation, and priority repair services. Although the MVME – 316 is obsolete, these services can help extend its useful life by several years, allowing industrial users to plan and budget for a more comprehensive system upgrade in the future.