Description

Detailed Parameter Table

| Parameter name | Parameter value |

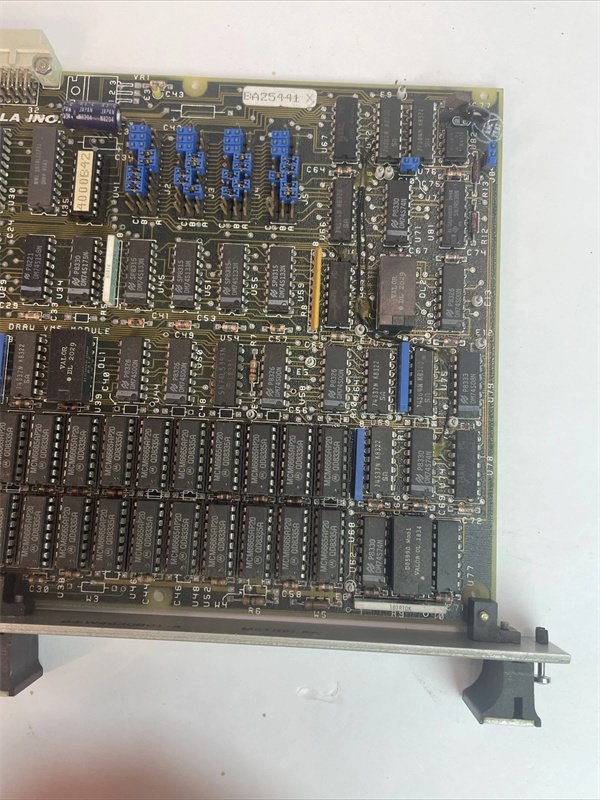

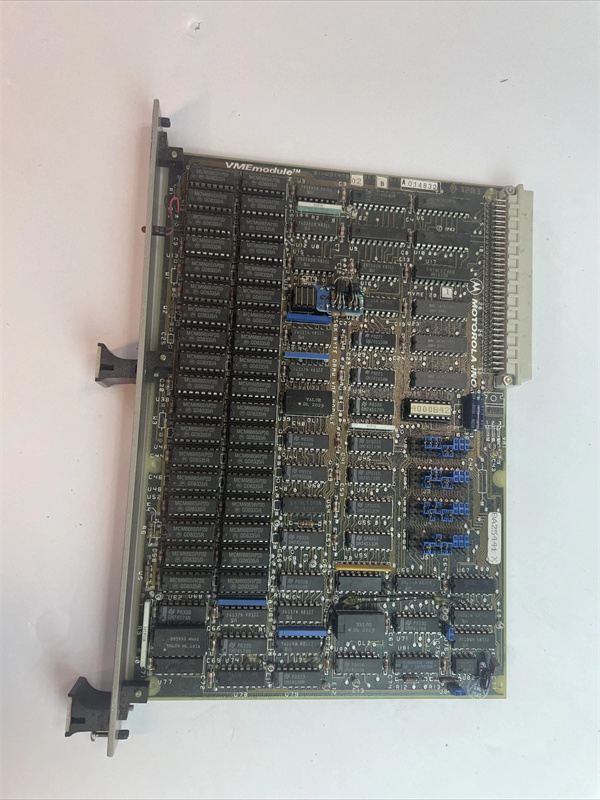

| Product model | Motorola MVME-201 |

| Manufacturer | Motorola (now part of Emerson Industrial Automation) |

| Product category | Legacy Industrial VMEbus Digital Input (DI) Module (dedicated discrete signal acquisition) |

| Digital Input (DI) Configuration | 64 channels (configurable as 64 differential or 128 single-ended); Sinking/sourcing compatible |

| Input Specifications | Voltage range: 5V DC (TTL) / 24V DC (industrial); Input current: 2mA (5V) / 10mA (24V); Input response time: <10 µs |

| Isolation | Channel-to-channel isolation: 250V AC (rms); Module-to-VMEbus isolation: 500V AC (rms); Transient surge protection: 1kV (1.2/50 µs) |

| Communication Interface | VMEbus A16/D16 slave interface (IEEE 1014-1987 compliant); Interrupt-driven data transfer (4 configurable vectors) |

| Environmental Requirements | Operating Temp: -20°C–70°C (-4°F–158°F); Storage Temp: -40°C–85°C (-40°F–185°F); Humidity: 5%–95% (non-condensing); Vibration: 10–2000 Hz, 1.8 g (rms); Shock: 60 g (peak, 1ms) |

| Physical Size | 3U VMEbus form factor: 100mm × 160.0mm (3.94in × 6.30in); Weight: 340g (0.75lbs) |

| Power Consumption | Typical: 6W (25°C, full load); Maximum: 9W (all 64 channels active) |

| Diagnostic Features | LED indicators (per 16-channel bank: DI status, power, fault); Open-circuit detection (all channels); Over-voltage protection |

| Compatible Host SBCs | Motorola MVME-214, Motorola MVME162-043, Motorola MVME-2700-761-I/O |

| Product Life Cycle | Discontinued/Obsolete |

Motorola MVME-201

Product Introduction

The Motorola MVME-201 is a legacy industrial VMEbus digital input module designed for high-channel discrete signal acquisition—specializing in converting on/off status from hundreds of digital sensors (e.g., limit switches, photoelectric sensors, proximity detectors) into digital data for VME-based automation systems. As a dedicated DI module in the Motorola MVME 200 series, Motorola MVME-201 differs from combined I/O modules like Motorola MVME-204-2 (32 DI/32 DO) by focusing exclusively on input functionality, delivering up to 128 single-ended channels to support large-scale sensor networks.

In automation architectures, Motorola MVME-201 acts as a “high-density sensor data hub”: it collects status signals from 64 differential (or 128 single-ended) sensors and transmits digitized data to host SBCs (such as Motorola MVME-214) via the VMEbus. This dedicated design eliminates the tradeoff of sacrificing input channels for output functionality, making Motorola MVME-201 ideal for legacy systems like multi-zone warehouse monitoring, automotive body-in-white assembly, or building fire safety systems—where replacing it would require rewiring hundreds of sensors and disrupt critical monitoring workflows.

Core Advantages and Technical Highlights

Ultra-High Channel Density: Motorola MVME-201 offers 64 differential or 128 single-ended DI channels—4x the single-ended density of Motorola MVME-204-2’s 32 DI channels. This reduces VMEbus slot usage by 75% for large sensor networks: a 50-zone warehouse requiring 100 “package present” sensors can use one Motorola MVME-201 (configured as 128 single-ended channels) instead of four Motorola MVME-204-2 modules, freeing slots for control or communication cards. For example, an automotive plant uses Motorola MVME-201 to monitor 96 “weld joint presence” sensors across a body assembly line—all in one 3U slot—simplifying chassis management and reducing wiring complexity.

Rapid Response + Fault Resilience: With an input response time of <10 µs, Motorola MVME-201 captures fast-changing sensor signals that slower modules miss—critical for high-speed applications like bottle capping lines, where a delayed “cap missing” signal could result in 100+ defective products per minute. The module also includes open-circuit detection and over-voltage protection: if a sensor cable breaks, Motorola MVME-201 triggers an immediate fault alert, allowing technicians to resolve issues in <30 minutes vs. hours of troubleshooting with non-diagnostic modules. Its 1.8 g vibration resistance further ensures stable sensor communication in high-vibration environments like stamping plants.

Flexible Sensor Compatibility: Motorola MVME-201 supports both 5V DC (TTL) and 24V DC (industrial) sensors, plus differential/single-ended configuration—eliminating the need for external signal conditioners or voltage converters. A food processing plant can use 24V DC differential channels to monitor high-current conveyor limit switches (resistant to EMI) and 5V DC single-ended channels to track low-power indicator light status, all via Motorola MVME-201. This flexibility reduces inventory costs, as one module replaces two voltage-specific alternatives, and simplifies integration with existing sensor fleets—avoiding the expense of replacing hundreds of legacy sensors.

Typical Application Scenarios

In automotive body-in-white assembly, Motorola MVME-201 is paired with Motorola MVME162-043 to monitor a 30-station welding line. Configured as 64 differential channels, it connects to 60 “part clamp” sensors (24V DC) and 4 “robot position” sensors (5V DC). The host SBC uses Motorola MVME-201’s data to verify all clamps are closed before activating welders—preventing costly part misalignment. The module’s <10 µs response time ensures the SBC receives “clamp open” signals in time to stop welding within 50 ms, avoiding $10,000+ in damaged parts per incident. Its open-circuit detection also alerts technicians to frayed sensor cables, reducing unplanned downtime by 35%.

For building fire safety systems, Motorola MVME-201 (configured as 128 single-ended channels) monitors 100 smoke detectors and 20 fire alarm pull stations across a 20-floor office building. It transmits detector status to a Motorola MVME-214 SBC, which triggers alarms and HVAC shutdowns if smoke is detected. The module’s -20°C–70°C operating range withstands unheated basement and rooftop enclosure temperatures, while its 500V AC module isolation prevents ground loops from disrupting fire alarm signals. Motorola MVME-201’s high density also reduces the fire control panel’s size by 50% compared to using smaller DI modules, fitting into tight mechanical rooms.

Related Model Recommendations

Motorola MVME-204-2: Combined DI/DO module complementary to Motorola MVME-201. Adds 32 DO channels for controlling actuators (e.g., relays, solenoids) in systems where Motorola MVME-201 handles extensive sensor monitoring.

Motorola MVME-201-L: Low-voltage variant of Motorola MVME-201 (5V DC only). Suitable for lab environments or consumer electronics manufacturing, where 24V DC sensors are not used.

Motorola MVME-332: 128-channel digital I/O module. Upgrades Motorola MVME-201 for hybrid systems needing both high DI density and 128 DO channels (e.g., large-scale factory automation).

Motorola MVME-214: Integrated controller compatible with Motorola MVME-201. Provides processing and user interface to analyze sensor data from the module—ideal for standalone monitoring systems.

Motorola MVME-050: Industrial power supply (±5V/±12V/24V DC, 85–264V AC). Powers Motorola MVME-201 and ensures stable voltage for its isolation circuitry, maintaining sensor signal integrity.

Motorola MVME-717: 32-channel digital input module. Complements Motorola MVME-201 by adding extra DI channels for systems exceeding 128 single-ended inputs (e.g., 150-zone warehouses).

Emerson MVME-201-R: Refurbished variant of Motorola MVME-201. Tested to original specs—cost-effective replacement for failing units in critical monitoring systems like fire safety or industrial process control.

Motorola MVME-201

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing Motorola MVME-201, verify the VMEbus chassis has a 3U slot and supports A16/D16 addressing. Confirm the power supply provides ±5V/±12V (for module logic) and 24V DC (for industrial sensors)—use a multimeter to check voltage tolerance ±3% (critical for isolation circuit stability). Gather tools: anti-static wristband (protects DI circuitry), torque screwdriver (0.3N·m for chassis mounting), wire crimpers (for sensor connections), and a laptop (for configuration via host SBC). Use shielded twisted-pair cables (24AWG) for differential channels and twisted-pair for single-ended—route separately from power cables (min 15cm separation) to avoid EMI interference.

Maintenance suggestions: For daily upkeep, check Motorola MVME-201’s bank LEDs—green for active sensors, red for open circuits/faults. Test 5% of channels bi-weekly via the host SBC (e.g., trigger a test sensor and verify data reception) to ensure responsiveness. Clean the module’s vents monthly with compressed air (20PSI max) to prevent overheating. If open-circuit faults occur, isolate the sensor (check cable continuity and termination) and reset the module via the host SBC. Store spare Motorola MVME-201 units in anti-static bags (15°C–25°C, 40%–60% humidity) to preserve isolation transformers and input circuitry.

Service and Guarantee Commitment

While Motorola MVME-201 is discontinued, Emerson and third-party legacy support providers offer refurbished units with an 18-month warranty—covering defects in materials (e.g., input buffers, isolation transformers) and workmanship. Refurbished Motorola MVME-201 units undergo full channel testing (all 128 single-ended channels) to ensure compliance with original response time and fault detection specs, providing reliable replacements for critical monitoring systems.

For extended support, providers offer 36-month service contracts including 24/7 remote troubleshooting (via phone/email), access to archived technical docs (wiring diagrams, calibration guides), and priority repair for complex issues (e.g., isolation circuit failures). This commitment ensures Motorola MVME-201 remains operational for 5–10 years in legacy setups, helping users avoid costly sensor rewiring or full-system upgrades while maintaining uninterrupted discrete signal monitoring.