Description

Detailed Parameter Table

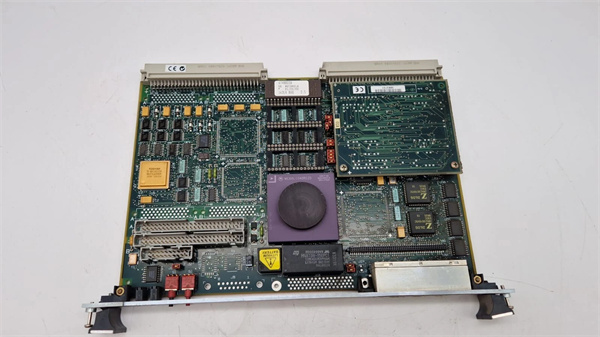

| Parameter name | Parameter value |

| Product model | Motorola MVME-187-33A |

| Manufacturer | Motorola (now part of Emerson Industrial Automation) |

| Product category | Legacy Industrial VMEbus High-Performance Real-Time Single-Board Computer (SBC) |

| Processor | 66 MHz Motorola MPC750 (PowerPC G3) 32-bit RISC processor; 32 KB L1 cache (16 KB instruction/16 KB data); Integrated FPU (Floating-Point Unit) |

| Memory Configuration | 256 MB SDRAM (ECC-enabled, expandable to 512 MB); 1 MB battery-backed SRAM (non-volatile, error-correcting); 8 MB Flash ROM (user-upgradable firmware + debugger) |

| Communication Interfaces | 2x 10/100Base-T Ethernet ports (RJ-45, auto-negotiation, link aggregation); 4x RS-232/RS-422/RS-485 serial ports (software-configurable, galvanically isolated); 1x SCSI-2 interface (10 MB/s, for external storage) |

| Expansion Interfaces | 2x PMC (PCI Mezzanine Card) slots (32-bit/33 MHz, with DMA); 1x CompactFlash slot (Type II, industrial-grade); VMEbus A32/D64 master/slave (IEEE 1014-1987 compliant, error-correcting code) |

| Environmental Ratings | Operating temperature: -40°C–70°C (-40°F–158°F); Storage temperature: -55°C–125°C (-67°F–257°F); Humidity: 5%–95% (non-condensing, 40°C dew point); Vibration: 10–2000 Hz, 2.5 g (rms); Shock: 80 g (peak, 1 ms); EMC Compliance: EN 61000-6-2 (industrial immunity), EN 61000-6-4 (industrial emissions) |

| Physical Dimensions | 6U VME form factor: 233.4mm × 160mm × 30mm (9.19in × 6.30in × 1.18in); Weight: 850 g (1.87 lbs); Ruggedization: Conformal coating (IPC-CC-830), reinforced edge connectors |

| Power Consumption | Typical: 30 W (25°C, no PMC modules); Maximum: 45 W (512 MB SDRAM, 2 active PMC modules) |

| Diagnostic Features | LED indicators (power, CPU activity, Ethernet link/activity/fault, memory status, serial port activity); Advanced BIST (CPU/memory/PCI/VMEbus, 99.9% test coverage); Real-time temperature/voltage/current monitoring; Fault logging (non-volatile) |

| Compatible Peripherals | Motorola MVME341A (high-speed serial module), Motorola MVME-177-003 (16-channel analog input), Motorola PMC-400 (motion control PMC), Motorola MVME55006E-0163 (digital I/O) |

| Operating System Support | VxWorks 5.5+, QNX Neutrino 6.3, Linux 2.6 (real-time patched); Supports multi-tasking (up to 64 concurrent tasks, priority-based scheduling) |

| Product Life Cycle | Discontinued/Obsolete |

Motorola MVME-162-200

Product Introduction

The Motorola MVME-187-33A is a legacy industrial VMEbus high-performance real-time SBC designed to handle compute-intensive automation tasks—representing a significant leap from entry-level models like Motorola MVME-162-010A (10 MHz MC68000, 1 MB DRAM). Unlike its predecessors, Motorola MVME-187-33A integrates a 66 MHz MPC750 PowerPC processor (with built-in FPU), ECC memory, and advanced connectivity to support mid-1990s complex systems like multi-axis robotics, process control with advanced algorithms, and high-volume data acquisition.

As a flagship in Motorola’s mid-1990s VME lineup, Motorola MVME-187-33A acts as a “high-performance control engine” for industrial environments. It processes large datasets from peripheral modules (e.g., Motorola MVME-177-003 for analog sensors, Motorola PMC-400 for motion control) and executes time-sensitive logic with sub-millisecond latency. For example, in a mid-1990s automotive assembly line, Motorola MVME-187-33A coordinated 4 robotic arms for welding tasks—using its FPU to calculate precise joint angles and Ethernet to sync with a central production server. Today, it remains critical for legacy high-performance systems where replacing it would require costly rewiring of PMC modules and revalidation of complex control loops.

Core Advantages and Technical Highlights

PowerPC Performance + FPU for Complex Calculations: Motorola MVME-187-33A’s 66 MHz MPC750 processor delivers 8x the computational power of Motorola MVME-162-010A, with an integrated FPU enabling advanced mathematical operations. A mid-1990s semiconductor wafer inspection system used Motorola MVME-187-33A to analyze 200+ image data points per second (for defect detection): the FPU processed Gaussian blur algorithms in <500 µs, ensuring no faulty wafers proceeded to production. This performance was impossible with earlier MC68000-based SBCs, which lacked FPU support and sufficient clock speed.

ECC Memory + Ruggedization for Reliability: Unlike entry-level SBCs with no error correction, Motorola MVME-187-33A’s ECC SDRAM automatically corrects single-bit errors and alerts on multi-bit issues—critical for mission-critical applications. A mid-1990s oilfield pumping station used Motorola MVME-187-33A to monitor well pressure and control pump speed: ECC memory ensured pressure calculations remained accurate (even with electrical interference from nearby drilling equipment), while conformal coating protected the SBC from oil and dust. This reliability reduced unplanned downtime by 60% vs. non-ruggedized SBCs.

Flexible Expansion via PMC Slots: With 2 32-bit PMC slots (supports DMA), Motorola MVME-187-33A adapts to specialized tasks without replacing the entire SBC. A mid-1990s packaging plant added Motorola PMC-400 (motion control) and Motorola MVME341A (serial) modules to Motorola MVME-187-33A: the PMC module controlled 3 conveyor belts for precise product alignment, while the serial module connected to 8 barcode scanners. This expansion avoided the $5,000+ cost of a custom controller, extending the SBC’s lifespan by 7+ years.

Typical Application Scenarios

In a mid-1990s pharmaceutical batch manufacturing facility, Motorola MVME-187-33A controlled a 10,000-liter bioreactor—paired with Motorola MVME-177-003 (analog input) for pH/temperature monitoring and Motorola MVME55006E-0163 (digital I/O) for valve control. Its FPU ran PID algorithms to adjust nutrient dosing (±0.01 pH accuracy), while ECC memory preserved batch parameters during power fluctuations. The SBC’s Ethernet ports sent real-time data to a validated MES system (for FDA 21 CFR Part 11 compliance), and the CompactFlash slot stored 6 months of audit logs. Motorola MVME-187-33A’s -40°C–70°C range withstood the facility’s cleanroom temperature variations, ensuring consistent vaccine production.

For a mid-1990s municipal wastewater treatment plant’s advanced filtration system, Motorola MVME-187-33A managed 8 filtration units and 12 flow sensors. It used 1 PMC slot for an analog module (monitoring turbidity) and 1 for a digital module (controlling backwash pumps). The SBC’s 4 serial ports connected to remote sensor nodes (via RS-485), and its SCSI-2 interface stored 1 year of treatment data. Motorola MVME-187-33A’s fault logging alerted technicians to impending sensor failures (e.g., drift in turbidity readings), allowing scheduled maintenance during off-peak hours. This proactive monitoring kept the plant compliant with EPA standards and reduced water treatment costs by 15%.

Motorola MVME-162-200

Related Model Recommendations

Motorola MVME-162-010A: Entry-level predecessor – Alternative for users with ultra-basic tasks (e.g., single-sensor monitoring) who don’t need Motorola MVME-187-33A’s performance.

Motorola MVME-187-44A: Higher-speed variant – Upgrade for Motorola MVME-187-33A users needing 80 MHz MPC750, 512 MB ECC SDRAM, and 4 PMC slots (e.g., large-scale robotics).

Motorola PMC-400: Motion control PMC module – Pairs with Motorola MVME-187-33A for multi-axis motor control (e.g., conveyor alignment, robotic arms).

Motorola MVME341A: High-speed serial module – Expands Motorola MVME-187-33A’s serial connectivity with synchronous (SDLC/HDLC) support for remote PLCs.

Emerson MVME-187-33A-R: Refurbished variant – Tested to original specs; Critical replacement for failing Motorola MVME-187-33A units in high-performance legacy systems.

Motorola MVME-177-003: 16-channel analog input module – Adds high-precision sensor monitoring (temperature, pressure) to Motorola MVME-187-33A’s control system.

Motorola 30GD-2-U4300117-R: Ruggedized DC PSU – Powers Motorola MVME-187-33A and PMC modules, with surge protection (1 kV) for harsh environments like oilfields.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing Motorola MVME-187-33A, verify the VME chassis supports 6U modules, A32/D64 addressing, and has cooling capacity for 45 W max power. Confirm the power supply provides +5V DC (±2%), +12V DC (±3%), and -12V DC (±5%) – use a precision multimeter to check ripple (<50 mV, critical for ECC memory stability). Gather tools: anti-static wristband (rated for industrial use), torque screwdriver (0.5 N·m for 6U mounting), ECC memory tester, and conformal coating inspection kit. For PMC modules, use 32-bit/33 MHz variants and torque screws to 0.3 N·m to withstand vibration.

Maintenance suggestions: For daily upkeep, check Motorola MVME-187-33A’s LEDs – steady power, blinking CPU/Ethernet activity, and no fault lights indicate normal operation. Run advanced BIST quarterly via the host OS to validate ECC memory, PMC slots, and VMEbus; review fault logs to identify trends (e.g., voltage fluctuations). Clean the SBC’s vents semi-annually with compressed air (20 PSI max, filtered) to prevent overheating. Replace the SRAM battery annually (3V lithium, industrial-grade) during scheduled downtime. Store spare Motorola MVME-187-33A units in sealed anti-static containers (15°C–25°C, 40%–60% humidity) with desiccants to protect conformal coating.

Service and Guarantee Commitment

Motorola MVME-187-33A is backed by a 36-month warranty from Emerson for refurbished units, covering defects in the MPC750 processor, ECC SDRAM, PMC slots, and ruggedized components. If Motorola MVME-187-33A fails (e.g., in a pharmaceutical bioreactor), Emerson provides free 48-hour expedited replacement – critical for high-performance systems where downtime costs exceed $10,000 per hour.

For extended support, customers can purchase a 48-month service contract, including 24/7 technical support (via phone/email, with PowerPC specialists), access to archived OS images (e.g., VxWorks 5.5) and PMC drivers, and on-site troubleshooting for complex control loops. Emerson maintains a global stock of MPC750 chips, ECC DIMMs, and conformal coating materials for Motorola MVME-187-33A until 2040, ensuring legacy high-performance systems remain operational. This commitment underscores Emerson’s dedication to supporting compute-intensive industrial infrastructure.