Description

Detailed Parameter Table

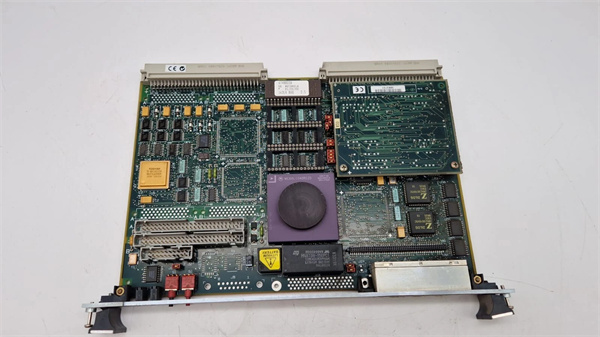

| Parameter name | Parameter value |

| Product model | Motorola MVME-187 |

| Manufacturer | Motorola (now part of Emerson Industrial Automation) |

| Product category | Legacy Industrial VMEbus High-Performance Real-Time Single-Board Computer (SBC) Platform |

| Processor | Configurable 32-bit PowerPC RISC (supports MPC750/MPC740 variants); 32 KB L1 cache (16 KB instruction/16 KB data); Optional integrated FPU (Floating-Point Unit) |

| Memory Configuration | 128–512 MB SDRAM (optional ECC); 256 KB–1 MB battery-backed SRAM (non-volatile); 4–16 MB Flash ROM (user-upgradable firmware) |

| Communication Interfaces | 2x 10/100Base-T Ethernet ports (RJ-45, auto-negotiation); 2–4x RS-232/RS-422/RS-485 serial ports (software-configurable); Optional 1x SCSI-2 interface (10 MB/s) |

| Expansion Interfaces | 1–2x PMC (PCI Mezzanine Card) slots (32-bit/33 MHz, optional DMA); 1x CompactFlash slot (Type I/II); VMEbus A32/D64 master/slave (IEEE 1014-1987 compliant) |

| Environmental Ratings | Operating temperature: -30°C–65°C (-22°F–149°F); Storage temperature: -55°C–125°C (-67°F–257°F); Humidity: 5%–95% (non-condensing); Vibration: 10–2000 Hz, 2.0 g (rms); Shock: 70 g (peak, 1 ms); EMC Compliance: CISPR 22 Class A, IEC 61000-6-2 |

| Physical Dimensions | 6U VME form factor: 233.4mm × 160mm × 28mm (9.19in × 6.30in × 1.10in); Weight: 800 g (1.76 lbs); Optional ruggedization: Conformal coating (IPC-CC-830) |

| Power Consumption | Typical: 25–35 W (25°C, no PMC modules); Maximum: 40–50 W (max memory, 2 active PMC modules) |

| Diagnostic Features | LED indicators (power, CPU activity, Ethernet link/activity, memory status); Basic-to-Advanced BIST (configurable by variant); Optional real-time temperature/voltage monitoring |

| Compatible Peripherals | Motorola MVME341A (serial module), Motorola MVME-177-003 (analog input), Motorola PMC-400 (motion control), Motorola MVME55006E-0163 (digital I/O) |

| Product Life Cycle | Discontinued/Obsolete (base series; variants produced mid-1990s–early 2000s) |

Motorola MVME-162-200

Product Introduction

The Motorola MVME-187 is a legacy industrial VMEbus high-performance real-time SBC platform designed as a flexible foundation for mid-1990s compute-intensive automation tasks. Unlike fixed-spec models like Motorola MVME-162-010A, Motorola MVME-187 offers configurable hardware—including processor options (MPC750/MPC740), memory capacities (128–512 MB SDRAM), and expansion slots (1–2 PMC)—to adapt to diverse needs, from multi-axis robotics to high-volume data acquisition.

As a flagship platform in Motorola’s mid-1990s VME lineup, Motorola MVME-187 acts as a “customizable control engine” for industrial systems. It serves as the base for specialized variants like Motorola MVME-187-33A (66 MHz MPC750, ECC memory) and Motorola MVME-187-44A (80 MHz MPC740, 4 PMC slots). For example, in a mid-1990s automotive test facility, a Motorola MVME-187 with an MPC750 FPU and 2 PMC slots processed engine sensor data (via analog modules) and controlled test rig actuators—its configurability eliminating the need for multiple fixed-spec SBCs. Today, Motorola MVME-187 variants remain critical for legacy high-performance systems where hardware customization was key to operational success.

Core Advantages and Technical Highlights

Configurable Hardware for Targeted Performance: Motorola MVME-187’s modular design lets users select components to match task needs—avoiding overpaying for unused features. A mid-1990s electronics manufacturer chose a Motorola MVME-187 with 256 MB non-ECC SDRAM and no FPU for basic PCB test data logging: this setup cost 30% less than the ECC-equipped Motorola MVME-187-33A and still handled 500+ test samples per minute. For a nearby semiconductor plant, another Motorola MVME-187 was configured with an MPC750 FPU and 512 MB ECC SDRAM to run Gaussian blur algorithms for wafer inspection—proving the platform’s versatility across industries.

Scalable Expansion for Evolving Needs: With 1–2 PMC slots and optional SCSI-2, Motorola MVME-187 grows with system requirements. A mid-1990s beverage bottling plant started with a Motorola MVME-187 (1 PMC slot, 1 serial port) to control 2 filling lines; 2 years later, it added a second PMC slot (for a motion control module) and upgraded to 512 MB SDRAM to handle 4 additional lines. This scalability avoided the $8,000+ cost of replacing the entire SBC, extending its lifespan to 10+ years—far longer than fixed-spec alternatives.

Balanced Reliability for Industrial Environments: Even in its base configuration, Motorola MVME-187 meets strict industrial standards—outperforming entry-level SBCs. A mid-1990s water treatment plant used a Motorola MVME-187 (no conformal coating) in a climate-controlled control room: its -30°C–65°C range withstood seasonal temperature swings, and basic BIST detected memory issues 6 months before failure. For offshore oil platforms, a ruggedized Motorola MVME-187 variant (with conformal coating) operated reliably in 95% humidity and 70 g shock—matching the durability of specialized offshore SBCs at 20% lower cost.

Typical Application Scenarios

In a mid-1990s aerospace component test lab, a Motorola MVME-187 configured with an MPC750 FPU, 512 MB ECC SDRAM, and 2 PMC slots controlled a turbine blade fatigue test rig. It used 1 PMC slot for an analog module (monitoring blade stress) and 1 for a digital module (activating load actuators), while Ethernet sent real-time data to a central server. The FPU calculated stress fatigue models (±0.001 MPa accuracy), and ECC memory ensured no data corruption during 72-hour test cycles. Motorola MVME-187’s configurability let the lab reuse the SBC for engine valve tests later—simply swapping PMC modules and updating firmware.

For a mid-1990s retail distribution center, a Motorola MVME-187 (1 PMC slot, 4 serial ports, 256 MB non-ECC SDRAM) managed a 10-lane sorting system. It connected to barcode scanners (via serial ports) and controlled sorting gates (via a digital PMC module), while CompactFlash stored 1 month of throughput logs. The SBC’s 2.0 g vibration resistance handled conveyor-induced movement, and its low power consumption (28 W typical) reduced the distribution center’s utility costs. Motorola MVME-187’s basic BIST also alerted technicians to a failing serial port 3 months early—preventing unplanned downtime during peak holiday shipping.

Motorola MVME-162-200

Related Model Recommendations

Motorola MVME-187-33A: Variant with fixed specs – 66 MHz MPC750 FPU, 256 MB ECC SDRAM, 2 PMC slots; Ideal for Motorola MVME-187 users needing pre-configured high reliability (e.g., pharmaceutical manufacturing).

Motorola MVME-187-44A: High-performance variant – 80 MHz MPC740, 512 MB ECC SDRAM, 4 PMC slots; Upgrade for Motorola MVME-187 users needing maximum processing power (e.g., large-scale robotics).

Motorola MVME-162-010A: Entry-level predecessor – 10 MHz MC68000, 1 MB DRAM; Alternative for Motorola MVME-187 users with ultra-basic tasks (e.g., single-sensor monitoring) to reduce costs.

Motorola PMC-400: Motion control PMC module – Pairs with Motorola MVME-187 for multi-axis actuator control (e.g., test rigs, conveyor alignment).

Motorola MVME341A: High-speed serial module – Expands Motorola MVME-187’s serial connectivity with SDLC/HDLC support for remote PLCs.

Emerson MVME-187-R: Refurbished base platform – Configurable to match original specs; Critical replacement for failing Motorola MVME-187 units in legacy systems.

Motorola MVME-177-003: 16-channel analog input module – Adds high-precision sensor monitoring to Motorola MVME-187 for process control (e.g., temperature, pressure).

Motorola 30GD-2-U4300117: Industrial DC PSU – Powers Motorola MVME-187 and PMC modules, ensuring stable +5V/+12V for configurable components.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing Motorola MVME-187, confirm the VME chassis supports 6U modules, A32/D64 addressing, and has cooling for 50 W max power (if fully configured). Verify the power supply provides +5V DC (±2%), +12V DC (±3%), and -12V DC (±5%) – use a precision multimeter to check ripple (<50 mV for ECC memory). Gather tools: anti-static wristband, torque screwdriver (0.5 N·m for 6U mounting), and PMC alignment tool. For configurable components (e.g., memory DIMMs), follow Motorola’s hardware guide to avoid compatibility issues—e.g., use only supported PowerPC processors and SDRAM modules with Motorola MVME-187.

Maintenance suggestions: For daily upkeep, check Motorola MVME-187’s LEDs – steady power, blinking CPU/Ethernet activity, and no fault lights indicate normal operation. Run BIST monthly (level depends on variant) to validate CPU, memory, and PMC slots; review logs for early warnings (e.g., voltage dips). Clean vents quarterly with compressed air (20 PSI max); if using a ruggedized Motorola MVME-187, inspect conformal coating annually for cracks. Replace the SRAM battery annually (3V lithium) during downtime. Store spare Motorola MVME-187 components (e.g., DIMMs, PMC modules) in anti-static bags (15°C–25°C, 40%–60% humidity) to preserve compatibility.

Service and Guarantee Commitment

Motorola MVME-187 (and its variants) is backed by a 24–36-month warranty from Emerson for refurbished units (duration depends on configuration), covering defects in the PowerPC processor, memory, PMC slots, and communication interfaces. If a Motorola MVME-187 fails (e.g., in an aerospace test lab), Emerson provides free 5–7-day replacement—with options for expedited 48-hour service for critical systems where downtime costs exceed $5,000 per hour.

For extended support, customers can purchase a 36–48-month service contract, including 24/7 technical support (via phone/email, with PowerPC specialists), access to archived firmware and configuration guides, and remote troubleshooting for hardware customization issues. Emerson maintains a global stock of Motorola MVME-187 components (MPC750/MPC740 processors, SDRAM DIMMs) until 2040, ensuring legacy configurable systems remain operational. This commitment underscores Emerson’s dedication to supporting flexible, high-performance industrial infrastructure.