Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | Motorola MVME172PA-644SE |

| Manufacturer | Motorola (now part of Emerson’s industrial automation portfolio) |

| Product Category | VMEbus High-Precision Analog Input/Output (I/O) Module (tailored for industrial process control with enhanced isolation) |

| Input Channel Configuration | 16 differential analog input channels (software-configurable for single-ended use); 22-bit ADC resolution (higher precision than 16-bit alternatives) |

| Output Channel Configuration | 4 analog output channels; 16-bit DAC resolution; voltage/current dual-mode per channel |

| Input Signal Range | ±10 VDC, ±5 VDC, ±2.5 VDC, ±1 VDC, 0–10 VDC, 0–5 VDC (software-selectable per channel); input impedance: 10 MΩ (minimizes sensor loading) |

| Output Signal Range | Voltage: ±10 VDC, ±5 VDC, 0–10 VDC, 0–5 VDC (±0.1% full-scale accuracy); Current: 4–20 mA, 0–20 mA (±0.2% full-scale accuracy) |

| Sampling Rate (Inputs) | Up to 300 kSPS (aggregate); 18.75 kSPS per channel (sequential sampling); 60 kSPS per channel (burst mode for transient capture) |

| Update Rate (Outputs) | Up to 30 kSPS per channel (simultaneous updates supported for closed-loop control) |

| Bus Standard | VMEbus (PICMG VME 3.0 compliant) – 32-bit address/data bus; master/slave dual-mode; VME64x support (200 MB/s peak transfer rate) |

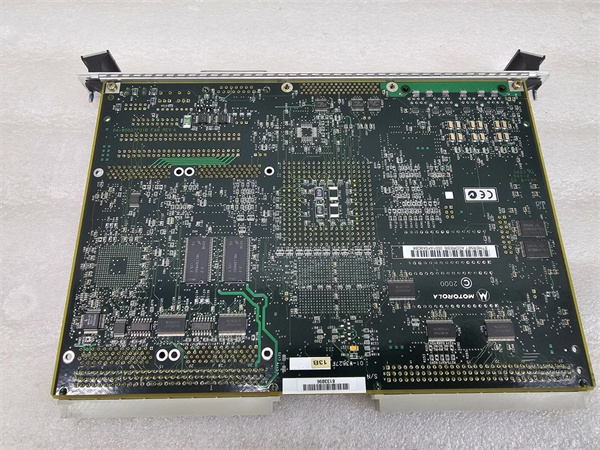

| Physical Dimensions | Standard 6U VME form factor (233.4 mm × 160 mm × 16 mm; L×W×H) – fits standard VME chassis slots |

| Power Requirements | +5 VDC (1.8 A typical, 2.5 A maximum); +12 VDC (0.6 A typical); -12 VDC (0.5 A typical); passive heat dissipation (heatsink with thermal pads for efficient cooling) |

| Signal Isolation | Channel-to-channel isolation (1500 Vrms); module-to-bus isolation (2500 Vrms); galvanic isolation for inputs/outputs (prevents ground loops) |

| Operating Temperature Range | -40°C – 70°C (-40°F – 158°F) (extended industrial temperature grade for harsh environments) |

| Product Status | Obsolete (discontinued by manufacturer; supported via aftermarket/refurbished services) |

| Compliance Standards | VMEbus 3.0; IEC 61010-1 (measurement equipment safety); FCC Class A (EMI); CE Mark; RoHS; IEC 61000-6-2/-4 (industrial EMC immunity/susceptibility) |

| Compatibility | Optimized for Motorola VME SBCs (MVME5500, MVME2434, MVME172-263/260); works with power modules (FAB 0340-1049, 01-W3324F)、communication modules (FLN4234A, MVME712/M)、I/O modules (MVME-204A728-1, MVME335) |

| On-Board Features | Programmable gain (1x, 2x, 4x, 8x, 16x); built-in self-test (BIST) for ADC/DAC validation; temperature-compensated calibration (0°C–70°C); output overcurrent protection (50 mA max per channel); per-channel status LEDs (input acquisition, output active, fault) |

MOTOROLA MVME172PA-652SE

Product Introduction

The Motorola MVME172PA-644SE is a high-precision VMEbus analog I/O module, engineered to deliver ultra-accurate signal acquisition and control for mission-critical industrial process control systems—filling the gap between standard analog modules (e.g., MVME162PA-344E) and specialized high-isolation modules (e.g., MVME-204A728-1). As a 6U VME form factor device, it integrates 16 high-resolution analog input channels (22-bit ADC) and 4 reliable analog output channels (16-bit DAC), making it ideal for applications where microscale signal accuracy (e.g., millivolt-level sensor readings) and robust isolation (e.g., in high-voltage industrial environments) are non-negotiable.

A defining strength of the MVME172PA-644SE is its seamless integration with the Motorola VME ecosystem. When paired with a high-performance SBC like the MVME5500, it leverages the VMEbus’s 32-bit data path and VME64x support to transmit high-volume, high-precision analog data—critical for tasks like real-time closed-loop control (e.g., regulating chemical reaction temperatures via 4–20 mA output signals) or transient event capture (e.g., detecting voltage spikes in power grid monitoring). It draws stable power from modules like the FAB 0340-1049 (for core analog circuits) and 01-W3324F (for auxiliary power), while its -40°C–70°C temperature range ensures reliability in extreme environments—from arctic oil pipeline monitoring stations to desert-based solar farm control cabinets.

Whether deployed in process manufacturing、power grid monitoring, or aerospace test benches, the MVME172PA-644SE acts as the “precision control backbone” of VME setups. Its 22-bit ADC delivers 100x higher resolution than 16-bit modules, enabling detection of microvolt-level signal changes, while its 2500 Vrms module-to-bus isolation protects the VME system from high-voltage transients. These features make it an indispensable component for legacy VME systems requiring both uncompromising precision and industrial-grade safety.

Core Advantages and Technical Highlights

22-Bit ADC for Ultra-High Precision Signal Acquisition

The MVME172PA-644SE’s 22-bit ADC delivers 0.000024% full-scale accuracy—over 100x more precise than 16-bit modules (e.g., MVME162PA-344E) and 4x more precise than 20-bit alternatives. This level of precision is critical for applications where even microvolt-level signal changes carry operational significance, such as in pharmaceutical manufacturing (monitoring 0.1 mV fluctuations in bioreactor pH) or power grid monitoring (detecting 50 µV spikes in transmission line voltage). For example, in a semiconductor wafer etching process, the module’s 22-bit resolution enables it to measure 1 µV variations in plasma sensor signals—ensuring etch depth is controlled to within 1 nanometer, a tolerance impossible to achieve with lower-resolution modules. The programmable gain (up to 16x) further amplifies weak sensor signals (e.g., 500 nV from a strain gauge) to the ADC’s optimal input range, maximizing measurement accuracy.

High-Isolation Design for Safety in High-Voltage Environments

With 1500 Vrms channel-to-channel isolation and 2500 Vrms module-to-bus isolation (exceeding MVME-204A728-1’s 250 Vrms), the MVME172PA-644SE eliminates ground loops and protects the VME system from high-voltage transients—critical for applications like power plant turbine control or high-voltage industrial motor monitoring. In a nuclear power plant’s auxiliary control system, for instance, the module’s isolation ensures that 480 VAC sensor power does not interfere with the 5 VDC VMEbus, preventing data corruption in critical temperature and pressure measurements. The galvanic isolation also simplifies system grounding design: each input channel can be grounded independently without causing cross-talk, a capability that reduces installation complexity and improves measurement stability in large-scale industrial systems.

VME64x Support for High-Speed Data Transfer

The MVME172PA-644SE’s compliance with VME 3.0 (including VME64x) enables 32-bit data transfers at up to 200 MB/s—5x faster than 16-bit VMEbus modules and essential for leveraging the module’s 300 kSPS aggregate sampling rate. This high-speed bus ensures that the MVME5500 SBC can capture and process every sample from the module’s 16 input channels without bottlenecks, even during burst mode (60 kSPS per channel). For example, in a wind farm’s turbine condition monitoring system, the module samples 16 vibration sensors at 30 kSPS each (480 kSPS aggregate), and the VME64x bus transmits this data to the MVME5500 in real time—enabling the SBC to detect 10 ms vibration spikes (indicative of bearing wear) before they escalate into catastrophic failures. This speed also supports closed-loop control applications, where low latency between data acquisition and output adjustment is critical (e.g., adjusting a valve within 5 ms of a pressure deviation).

Temperature-Compensated Calibration for Long-Term Stability

The MVME172PA-644SE’s temperature-compensated calibration adjusts the ADC/DAC’s output based on ambient temperature, minimizing drift (typically <0.0001% per °C) across its -40°C–70°C operating range. Unlike uncompensated modules, which can drift by 0.01% per °C (rendering measurements unreliable in temperature-fluctuating environments), this feature ensures the module maintains 22-bit precision even as conditions change. For example, in a desert-based solar farm where control cabinet temperatures swing from -10°C (night) to 70°C (day), the module’s temperature compensation ensures that irradiance sensor readings (critical for optimizing solar panel output) remain accurate to ±0.1%—avoiding costly over/under-production of energy. The built-in self-test (BIST) further validates ADC/DAC functionality on startup or demand, allowing technicians to confirm calibration integrity without external test equipment.

Typical Application Scenarios

Pharmaceutical Bioreactor Control

In a pharmaceutical bioreactor system, the MVME172PA-644SE (paired with MVME5500 SBC) manages precision process control: 8x analog input channels sample bioreactor pH (0–5 VDC, 22-bit resolution) and dissolved oxygen (0–10 VDC) sensors, detecting 0.1 mV fluctuations in pH (equivalent to 0.001 pH units) to ensure cell growth conditions remain optimal. 4x analog output channels regulate nutrient dosing pumps (4–20 mA) and heating elements (0–10 VDC), with the MVME5500 using closed-loop control to adjust outputs within 5 ms of a sensor deviation. The module’s 2500 Vrms isolation protects the VME system from high-voltage transients in the bioreactor’s heating circuit, while its passive cooling design avoids contamination in the cleanroom environment (no fan-induced particle generation).

Power Grid Transmission Line Monitoring

In a high-voltage power grid monitoring station, the MVME172PA-644SE (paired with MVME2434 SBC) captures critical electrical signals: 12x analog input channels sample transmission line voltage (±10 VDC, scaled from 110 kV) and current (±5 VDC, scaled from 1000 A) sensors, detecting 50 µV voltage spikes (indicative of lightning strikes or equipment faults). 4x analog output channels send control signals to protective relays (4–20 mA), triggering circuit breakers within 10 ms of a fault detection. The module’s 1500 Vrms channel-to-channel isolation prevents cross-talk between high-voltage sensor signals, while its -40°C operating range ensures reliability in winter storm conditions. The FLN4234A communication module transmits the module’s data to a central SCADA system, enabling grid operators to monitor and respond to faults in real time.

Aerospace Engine Test Bench

In an aerospace engine test facility, the MVME172PA-644SE (paired with MVME172-263/260 SBC) measures high-precision engine parameters: 16x analog input channels sample fuel pressure (±2.5 VDC), exhaust gas temperature (0–10 VDC), and vibration (±1 VDC) sensors, with the 22-bit ADC capturing 1 µV variations in vibration signals (critical for detecting early-stage bearing wear). 4x analog output channels control test bench valves (0–5 VDC) and fuel flow meters (4–20 mA), with the SBC using the module’s data to replicate in-flight engine conditions. The module’s temperature-compensated calibration ensures accuracy across the test chamber’s -20°C–60°C temperature range, while its BIST feature validates ADC functionality between test runs—meeting strict aerospace testing standards (e.g., DO-160).

MOTOROLA MVME172PA-652SE

Related Model Recommendations

Motorola MVME5500: VME SBC. Host controller for MVME172PA-644SE; processes 22-bit analog data, executes closed-loop control logic, and leverages VME64x to capture high-speed transient data—critical for maximizing the module’s precision.

Motorola FAB 0340-1049: Power supply module. Primary power source for MVME172PA-644SE; delivers stable ±12 VDC (for isolation circuits) and +5 VDC (for ADC/DAC) to support the module’s high-precision components.

Motorola 01-W3324F: Power distribution terminal block. Supplies auxiliary power to MVME172PA-644SE (if VME backplane power is insufficient) and distributes 24 VDC to connected sensors/actuators (e.g., bioreactor pH probes).

Motorola FLN4234A: Communication expansion module. Complements MVME172PA-644SE in large systems; transmits the module’s high-precision data to remote SCADA/cloud platforms via 4x Ethernet ports, enabling centralized monitoring.

Motorola MVME-204A728-1: Analog conditioning + digital I/O module. Works with MVME172PA-644SE in hybrid systems; adds isolated digital I/O for controlling relays/valves, while the MVME172PA-644SE focuses on high-precision analog acquisition.

Emerson RSTi-EP AI/AO Module: Modern Ethernet-based I/O. Replacement for MVME172PA-644SE in systems migrating to Ethernet; offers 24-bit ADC resolution, Gigabit Ethernet connectivity, and compatibility with MVME5500 via protocol conversion.

Keysight 3458A: Precision multimeter. Calibration tool for MVME172PA-644SE; provides NIST-traceable voltage/current references to validate the module’s 22-bit ADC accuracy during maintenance.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing MVME172PA-644SE, power off the VME chassis and disconnect the FAB 0340-1049 and 01-W3324F power supplies to prevent electrical shock. Verify the chassis has an available 6U VME slot and that the VME backplane is VME 3.0 compliant (for VME64x functionality). Check the power supply capacity: ensure it can deliver +5 VDC (2.5 A max), +12 VDC (0.6 A), and -12 VDC (0.5 A) to avoid underpowering the module’s ADC and isolation circuits. Use an anti-static wristband and mat to protect the module’s 22-bit ADC from ESD damage—even a small electrostatic discharge can degrade its precision. Gather tools: Phillips-head screwdriver (for chassis mounting), shielded twisted-pair cables (for analog inputs, 22–18 AWG), torque wrench (0.5–0.8 N·m for terminal screws), and a precision multimeter (±0.0001 V accuracy for calibration). Avoid installing near high-voltage equipment (e.g., transformers) or high-noise sources (e.g., variable-frequency drives) to prevent EMI interference with analog signals.

Commissioning and Maintenance

For commissioning, insert the MVME172PA-644SE into the VME slot and secure it with chassis screws. Connect analog sensors to the module’s differential input terminals (use shielded cables to