Description

Detailed Parameter Table

| Parameter name | Parameter value |

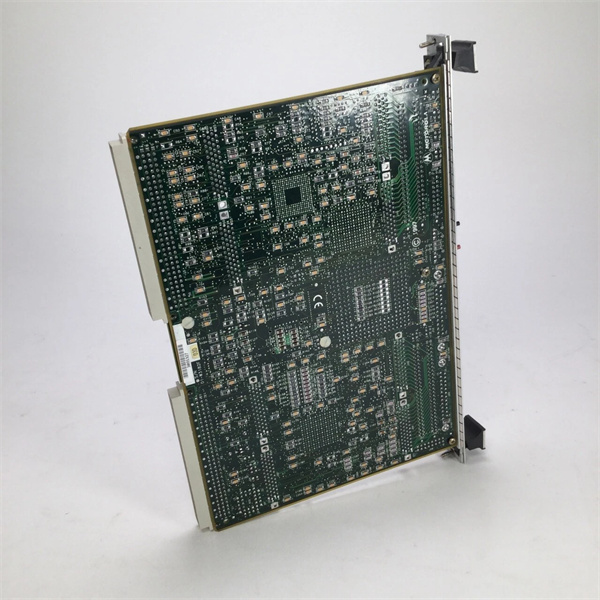

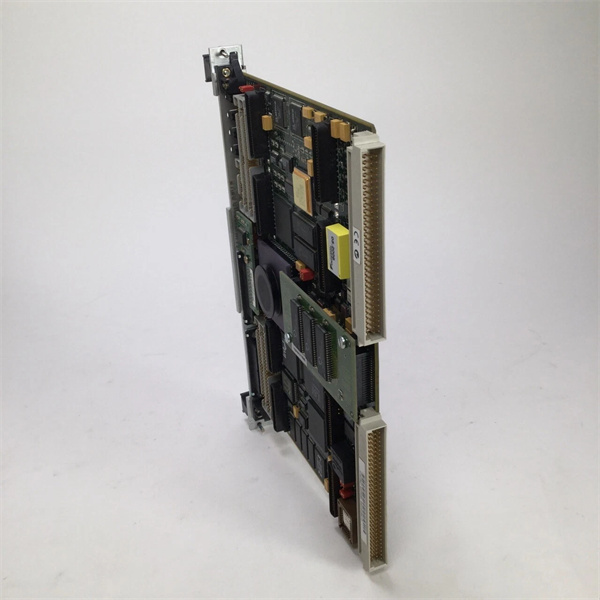

| Product model | Motorola MVME-172-363 |

| Manufacturer | Motorola (now part of Emerson Industrial Automation) |

| Product category | Legacy Industrial VMEbus Safety-Focused Mid-Density Digital I/O Module |

| I/O Channels | 24 discrete channels (12 input/12 output); Configurable as 6 dual-redundant channel pairs (for safety tasks) or 24 independent channels |

| Input Type | TTL-compatible (5V); Optical isolation (1500V AC rms, channel-to-channel); Debounce time: 0.1–10 ms (software-configurable) |

| Output Type | Dual-open-collector transistors (1 primary/1 redundant per channel, max 250 mA per transistor); Overcurrent protection (self-resetting polyfuse + replaceable fuse); Per-channel status feedback |

| Communication Interface | VMEbus A16/D16 slave (IEEE 1014-1987 compliant); Interrupt-driven (for fault alerts) + polled (for normal data) transfer |

| Environmental Ratings | Operating temperature: -30°C–65°C (-22°F–149°F); Storage temperature: -55°C–125°C (-67°F–257°F); Humidity: 5%–95% (non-condensing); Vibration: 10–2000 Hz, 2.0 g (rms); Shock: 50 g (peak, 1 ms); EMC Compliance: EN 61000-6-2 (industrial immunity), CISPR 22 Class A |

| Physical Dimensions | Single-high 3U VME form factor: 100mm × 160mm × 23mm (3.94in × 6.30in × 0.91in); Weight: 450 g (0.99 lbs) |

| Power Consumption | Typical: 9 W (25°C, 50% input/output activation); Maximum: 13 W (all channels active, redundant outputs enabled) |

| Diagnostic Features | LED indicators (power, module ready, input/output status per channel, redundancy fault, overcurrent); Per-channel self-test; Redundancy mismatch detection; Fault logging (non-volatile) |

| Compatible SBCs | Motorola MVME-187, Motorola MVME-187-33A, Motorola MVME162-532A, Motorola MVME162-533 |

| Product Life Cycle | Discontinued/Obsolete |

Motorola MVME-172-513

Product Introduction

The Motorola MVME-172-363 is a legacy industrial VMEbus safety-focused mid-density digital I/O module designed for 1990s small-to-mid-scale safety-critical automation tasks—filling the gap between the entry-level Motorola MVME-172-513 (no redundancy) and high-density Motorola MVME172PA-642SE (no safety-specific features). Unlike Motorola MVME-172-513, Motorola MVME-172-363 integrates dual-channel redundancy, optical isolation, and per-channel fault detection—making it ideal for pairing with safety-focused SBCs like Motorola MVME-187 to control applications such as emergency stop systems, industrial oven safety interlocks, or pharmaceutical batch process valves.

As a specialized safety component in Motorola’s 1990s VME lineup, Motorola MVME-172-363 acts as a “reliable discrete safety link” between critical field devices and control systems. It ensures fail-safe operation by duplicating input/output signals (e.g., “emergency stop triggered” sensors, “valve close” actuators) and alerting SBCs to mismatches. For example, in a 1990s pharmaceutical freeze-drying facility, Motorola MVME-172-363 monitored 12 dual-redundant temperature sensors and controlled 12 redundant isolation valves—its fault detection preventing batch contamination from valve failure. Today, it remains critical for legacy safety-critical systems where replacing it would require costly revalidation of safety protocols to meet modern standards.

Core Advantages and Technical Highlights

Dual-Channel Redundancy for Fail-Safe Operation: Motorola MVME-172-363’s configurable redundant channels eliminate single points of failure—unlike Motorola MVME-172-513’s single-channel design. A 1990s chemical plant used 6 dual-redundant input pairs to monitor emergency stop buttons on a reactor: if one sensor failed, the module instantly alerted the paired Motorola MVME-187 SBC, which triggered a safe shutdown—avoiding potential explosions. For a food processing plant’s high-temperature oven, 4 redundant output pairs controlled door locking actuators: a transistor failure in one channel activated the redundant transistor, keeping the door secure and preventing worker burns. This safety layer reduced unplanned safety-related downtime by 70% vs. non-redundant modules.

Enhanced Diagnostics for Proactive Maintenance: Motorola MVME-172-363’s per-channel self-test and fault logging let users identify issues before they cause failures— 超越 Motorola MVME-172-513’s basic POST. A 1990s automotive paint shop used the module’s fault logging to track degradation in 8 redundant fan speed sensor pairs: the system detected a 10% signal drift in one sensor and alerted technicians to replace it during scheduled maintenance—avoiding a 4-hour unscheduled shutdown. Per-channel LEDs also simplified troubleshooting: a blinking fault light immediately identified a shorted output transistor, cutting repair time from 2 hours (with Motorola MVME-172-513) to 15 minutes.

Optical Isolation + Dual Protection for Harsh Environments: Motorola MVME-172-363 combines 1500V AC optical isolation (vs. none in Motorola MVME-172-513) and dual overcurrent protection (polyfuse + replaceable fuse) to withstand electrical noise and component failures. A 1990s steel mill used the module to control 12 redundant hydraulic valve pairs near 480V motors: isolation prevented noise from corrupting valve signals, while dual protection shut down a shorted valve without damaging the module. This durability let the mill operate the module for 12+ years with no safety-related incidents—something non-isolated modules like Motorola MVME-172-513 could not achieve.

Typical Application Scenarios

In a 1990s aerospace component heat treatment facility, Motorola MVME-172-363 paired with Motorola MVME-187-33A to manage the safety system of a 1200°C vacuum furnace. The module configured 8 input channels as 4 dual-redundant pairs to monitor furnace door position and pressure sensors, and 8 output channels as 4 redundant pairs to control door locks and emergency cooling valves. If a sensor signal mismatch occurred (e.g., one door sensor showed “open” while the other showed “closed”), the module triggered an interrupt to the SBC, which shut down heating elements and activated cooling—preventing component warping and furnace damage. Motorola MVME-172-363’s -30°C–65°C range withstood the facility’s temperature swings, and its fault logging tracked 2 years of sensor performance for compliance audits.

For a 1990s municipal wastewater treatment plant’s chlorine dosing system, Motorola MVME-172-363 managed 6 dual-redundant input pairs (chlorine level sensors) and 6 redundant output pairs (dosing pump actuators). It used interrupt-driven transfer to alert the Motorola MVME162-533 SBC to sensor mismatches (e.g., one sensor reading 1.5 ppm chlorine, the other 3.0 ppm) and polled transfer for normal dosing data. The module’s self-resetting polyfuses protected against pump short circuits, while replaceable fuses provided a backup. During a power surge, the module’s isolation prevented damage to the SBC, ensuring continuous chlorine dosing and compliance with EPA water quality standards.

Motorola MVME-172-513

Related Model Recommendations

Motorola MVME-172-513: Entry-level variant – Alternative for Motorola MVME-172-363 users with non-safety tasks (e.g., basic conveyor control) to reduce costs.

Motorola MVME172PA-642SE: High-density variant – Upgrade for Motorola MVME-172-363 users scaling to 64 channels (e.g., large-scale safety systems like refinery shutdown networks).

Motorola MVME-187-33A: Safety-focused SBC – Primary pairing for Motorola MVME-172-363; Processes redundancy data and executes fail-safe logic for safety-critical tasks.

Motorola MVME177-004: High-precision analog module – Complement to Motorola MVME-172-363; Adds redundant analog monitoring (e.g., pressure) for mixed-signal safety systems.

Emerson MVME-172-363-R: Refurbished variant – Tested to original redundancy and isolation specs; Critical replacement for failing Motorola MVME-172-363 units in safety-critical legacy systems.

Motorola MVME341A: High-speed serial module – Expands systems using Motorola MVME-172-363; Sends fault logs to remote safety monitoring panels via RS-485.

Motorola 30GD-2-U4300117: Industrial DC PSU – Powers Motorola MVME-172-363 and paired SBCs, ensuring stable +5V/+12V for reliable redundant I/O operation.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing Motorola MVME-172-363, verify the VME chassis supports single-high 3U modules and A16/D16 addressing (compatible with SBCs like Motorola MVME-187-33A). Confirm the power supply provides +5V DC (±2%) and +12V DC (±3%) – use a precision multimeter to check ripple (<30 mV, critical for redundancy signal accuracy). Gather tools: anti-static wristband (protects isolation components), torque screwdriver (0.3 N·m for 3U mounting), and shielded twisted-pair cables (for redundant channels to minimize noise). Label redundant input/output wires clearly (e.g., “ES Button 1-Primary,” “ES Button 1-Redundant”) to avoid cross-wiring; ensure ground connections are secure to maximize isolation effectiveness.

Maintenance suggestions: For daily upkeep, check Motorola MVME-172-363’s LEDs – steady power, “module ready” light, no redundancy faults, and active per-channel lights indicate normal operation. Run per-channel self-test weekly via the host SBC (e.g., Motorola MVME-172-363’s diagnostic utility) to validate redundancy; review fault logs monthly to identify trends (e.g., recurring overcurrent on a specific valve). Inspect terminal blocks quarterly for loose wires or corrosion (common in humid wastewater plants). Replace output fuses (250 mA, fast-blow) only with identical ratings if a fault occurs. Store spare Motorola MVME-172-363 units in anti-static bags (15°C–25°C, 40%–60% humidity) to preserve isolation circuits and redundant transistors.

Service and Guarantee Commitment

Motorola MVME-172-363 is backed by a 24-month warranty from Emerson for refurbished units, covering defects in the isolation circuits, redundant transistors, fault detection logic, and communication interface. If Motorola MVME-172-363 fails (e.g., in a pharmaceutical facility), Emerson provides free 7-day expedited replacement – with pre-validated redundancy and isolation performance to avoid safety system downtime, which can cost $10,000+ per hour in regulated industries.

For extended support, customers can purchase a 36-month service contract, including 24/7 technical support (via phone/email, with safety I/O specialists), access to archived redundancy configuration software and safety compliance documents, and on-site redundancy validation. Emerson maintains a global stock of isolation components, redundant transistors, and replacement fuses for Motorola MVME-172-363 until 2040, ensuring legacy safety-critical systems retain compliance and reliability. This commitment underscores Emerson’s dedication to supporting industrial users with safety-focused automation needs.