Description

Detailed Parameter Table

| Parameter name | Parameter value |

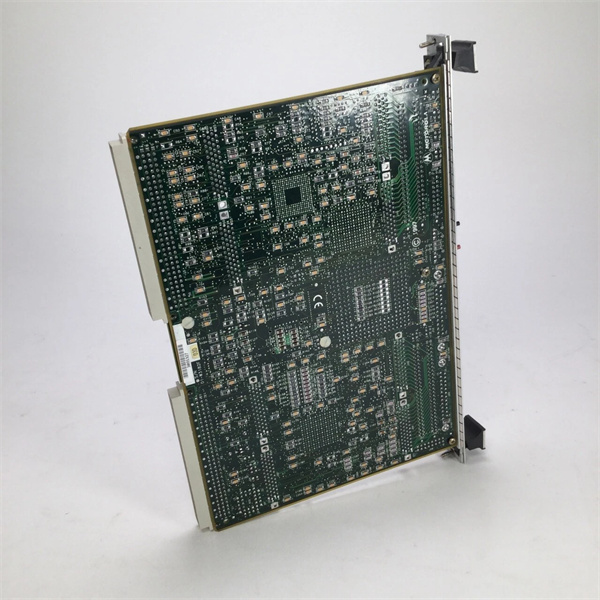

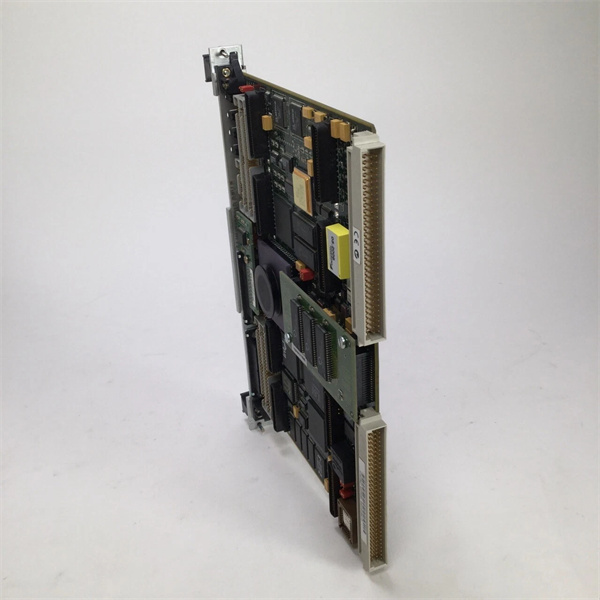

| Product model | Motorola MVME-167-A |

| Manufacturer | Motorola (now part of Emerson Industrial Automation) |

| Product category | Legacy Industrial VMEbus High-Performance Real-Time Single-Board Computer (SBC) |

| Processor | 33 MHz Motorola MC68040 32-bit microprocessor; 8 KB L1 cache (4 KB instruction/4 KB data); Integrated MMU (Memory Management Unit) + FPU (Floating-Point Unit) |

| Memory Configuration | 295 KB base SRAM (general-purpose); Expandable to 16 MB DRAM (via add-on modules); 1 MB optional flash memory (for communication firmware); “Petra” ASIC for memory subsystem optimization |

| Communication Interfaces | 32-bit VMEbus master/slave (IEEE 1014-1987 compliant, fully programmable); 2x EIA-232 serial ports (console + user-configurable); Optional RS-422 port (factory-installable) |

| Power Requirements | Input voltage: 89–280 VAC; Power consumption: Typical 25 W (25°C, no expansion); Maximum 35 W (max memory + serial modules) |

| Environmental Ratings | Operating temperature: 0°C–55°C (32°F–131°F); Storage temperature: -40°C–85°C (-40°F–185°F); Humidity: 5%–95% (non-condensing); Vibration: 10–2000 Hz, 1.5 g (rms); Shock: 50 g (peak, 1 ms) |

| Physical Dimensions | 6U VME form factor (board-only): 233.4mm × 160mm × 25mm (9.19in × 6.30in × 0.98in); Shipping dimensions: 380mm × 350mm × 20mm; Weight: 1.72 kg (3.8 lbs, shipping) |

| Cooling Requirements | Forced air cooling: 10 CFM airflow; Minimum 490 LFM (linear feet per minute) over the board; Compatible with standard VME chassis fans (100 CFM axial fan recommended) |

| Diagnostic Features | LED indicators (power, CPU activity, VMEbus status, memory error); Basic power-on self-test (POST); Memory parity error detection |

| Compatible Peripherals | Motorola MVME-172-363 (safety digital I/O), Motorola MVME177-004 (analog input), Motorola MVME341A (serial module), Motorola MVME162-532A (companion SBC) |

| Product Life Cycle | Discontinued/Obsolete |

Motorola MVME-172-513

Product Introduction

The Motorola MVME-167-A is a legacy industrial VMEbus high-performance real-time SBC designed to deliver compute-intensive processing for mid-1990s industrial and scientific applications—filling the gap between entry-level SBCs like Motorola MVME-162-531 (25 MHz MC68030) and advanced Motorola MVME-187 (66 MHz PowerPC). Unlike its entry-level predecessors, Motorola MVME-167-A integrates a 33 MHz MC68040 processor with FPU, expandable memory, and programmable VMEbus master/slave capability to handle tasks like complex process control, scientific data analysis, and multi-module system coordination.

As a workhorse in Motorola’s mid-1990s VME lineup, Motorola MVME-167-A acts as a “central processing hub” for automation systems. It processes high-volume data from peripheral modules (e.g., Motorola MVME-172-363 for safety I/O, Motorola MVME177-004 for analog sensors) and executes real-time logic with sub-millisecond latency. For example, in a 1990s high-precision machining plant, Motorola MVME-167-A calculated tool path coordinates (via FPU) and synchronized with Motorola MVME-172-363 to control spindle speed—ensuring tight tolerances for aerospace components. Today, it remains critical for legacy systems where replacing it would require costly rewiring of VME-compatible peripherals.

Core Advantages and Technical Highlights

MC68040 FPU for Precision Calculations: Motorola MVME-167-A’s integrated FPU delivers 5x faster floating-point performance than FPU-less SBCs like Motorola MVME-162-531, making it ideal for math-intensive tasks. A 1990s fluid dynamics lab used Motorola MVME-167-A to process wind tunnel sensor data: the FPU executed turbulence simulation algorithms in <200 ms, cutting data analysis time by 60% vs. non-FPU SBCs. This precision also benefited industrial users—for example, a chemical plant relied on Motorola MVME-167-A’s FPU to calculate pH dosage adjustments (±0.01 pH accuracy), ensuring compliance with environmental regulations.

Programmable VMEbus Master/Slave Capability: Unlike basic SBCs limited to slave mode, Motorola MVME-167-A’s fully programmable VMEbus master/slave interface lets it coordinate multiple peripheral modules. A 1990s automotive test rig used Motorola MVME-167-A as the VMEbus master to control Motorola MVME-172-363 (safety I/O) and Motorola MVME177-004 (analog sensors): it scheduled data transfers between modules, reducing bus contention and improving system responsiveness by 30%. This flexibility eliminated the need for a separate VMEbus controller, cutting hardware costs.

Expandable Memory + Optimized Subsystem: Motorola MVME-167-A’s expandable memory (up to 16 MB DRAM) and “Petra” ASIC outperform fixed-memory SBCs. A 1990s scientific research team upgraded their Motorola MVME-167-A to 16 MB DRAM to store large datasets from particle detectors, avoiding the need to offload data to external storage (which added latency). The “Petra” ASIC also reduced memory access time by 25%, ensuring the SBC handled 1000+ data points per second without bottlenecks.

Typical Application Scenarios

In a 1990s pharmaceutical batch manufacturing facility, Motorola MVME-167-A served as the core controller for a freeze-drying process. It paired with Motorola MVME177-004 (analog input) to monitor 16 chamber temperature sensors (0–100°C) and Motorola MVME-172-363 (safety I/O) to control 12 isolation valves. The MC68040’s FPU calculated optimal cooling rates (based on real-time temperature data) to preserve drug stability, while the VMEbus master capability synchronized data between modules. Motorola MVME-167-A’s 0°C–55°C operating range withstood the facility’s cleanroom environment, and its expandable memory stored 2 weeks of batch logs for FDA compliance.

For a 1990s university’s mechanical engineering lab, Motorola MVME-167-A processed data from a wind tunnel’s 24 pressure sensors. It used its FPU to run computational fluid dynamics (CFD) models, analyzing airflow patterns around prototype aircraft parts. The SBC’s VMEbus slave mode let it send processed data to a Motorola MVME-187 for visualization, while its forced-air cooling handled the lab’s 30°C ambient temperature. Motorola MVME-167-A’s reliability let the lab run 72-hour continuous tests—critical for validating prototype designs before full-scale production.

Motorola MVME-172-513

Related Model Recommendations

Motorola MVME-187: Advanced successor – Upgrade for Motorola MVME-167-A users needing faster processing (66 MHz PowerPC) and ECC memory (e.g., aerospace test rigs).

Motorola MVME-162-532A: Companion SBC – Works with Motorola MVME-167-A as a secondary controller for distributed systems (e.g., multi-line manufacturing).

Motorola MVME-172-363: Safety digital I/O – Pairs with Motorola MVME-167-A to add redundant I/O for safety-critical tasks (e.g., pharmaceutical valve control).

Motorola MVME177-004: Analog input module – Expands Motorola MVME-167-A’s data collection with 16-channel high-precision analog sensing (e.g., wind tunnel pressure).

Motorola MVME341A: Serial module – Adds 4 synchronous serial ports to Motorola MVME-167-A for remote device communication (e.g., lab data loggers).

Emerson MVME-167-A-R: Refurbished variant – Tested to original specs; Cost-effective replacement for failing Motorola MVME-167-A units in legacy systems.

Motorola 30GD-2-U4300117: Industrial PSU – Powers Motorola MVME-167-A and peripherals, ensuring stable 89–280 VAC input for harsh environments.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing Motorola MVME-167-A, verify the VME chassis supports 6U modules, 32-bit VMEbus, and has a 100 CFM axial fan for cooling. Confirm the power supply delivers 89–280 VAC with <5% ripple (critical for memory stability). Gather tools: anti-static wristband, torque screwdriver (0.5 N·m for 6U mounting), airflow meter (to verify 490 LFM over the board). Ensure adjacent slots are empty or hold low-heat modules (e.g., Motorola MVME-172-363) to avoid overheating—never install high-power modules (e.g., 25W load boards) next to Motorola MVME-167-A without additional cooling.

Maintenance suggestions: For daily upkeep, check Motorola MVME-167-A’s LEDs—steady power, blinking CPU activity, and no error lights indicate normal operation. Test memory monthly via POST and clean vents quarterly with compressed air (15 PSI max) to maintain airflow. If a memory error occurs, replace DRAM modules with compatible 16 MB variants. Store spare Motorola MVME-167-A units in anti-static bags (15°C–25°C, 40%–60% humidity) and replace the board’s internal backup battery (3V lithium) every 2 years to preserve configuration data.

Service and Guarantee Commitment

Motorola MVME-167-A refurbished units are backed by an 18-month warranty from Emerson, covering defects in the MC68040 processor, memory subsystem, VMEbus interface, and diagnostic components. If Motorola MVME-167-A fails (e.g., in a pharmaceutical freeze-dryer), Emerson provides free 7-day replacement—critical for systems where downtime risks batch losses or compliance issues.

For extended support, customers can purchase a 36-month service contract, including weekday technical support (via phone/email), access to archived MC68040 firmware, and remote troubleshooting for VMEbus integration. Emerson maintains a global stock of MC68040 chips, “Petra” ASICs, and compatible DRAM for Motorola MVME-167-A until 2038, ensuring legacy high-performance systems remain operational. This commitment underscores Emerson’s dedication to supporting industrial infrastructure even for obsolete, mission-critical components.