Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

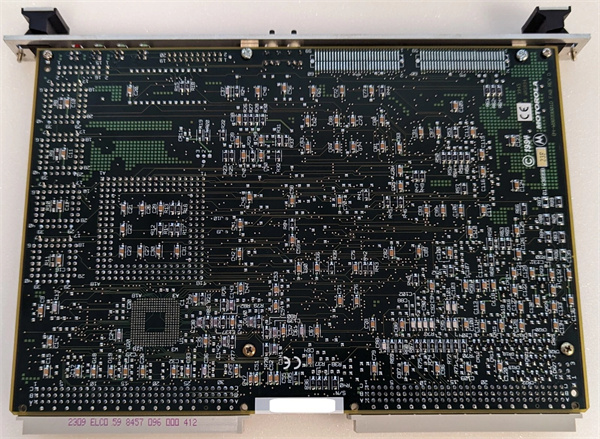

| Product model | Motorola MVME-167-32B |

| Manufacturer | Motorola (now part of Emerson’s Industrial Automation Portfolio) |

| Product category | VMEbus Industrial High-Performance Single-Board Computer (SBC) – MVME-167 Series |

| Processor | 33 MHz Motorola MC68040 32-bit microprocessor (with on-chip FPU, MMU, 8KB cache) |

| Memory Configuration | 32 MB ECC-protected DRAM (non-expandable); 256 KB battery-backed SRAM; 1 MB flash (firmware storage); battery-powered time-of-day (TOD) clock |

| Communication Interfaces | 2x EIA-232-D serial ports (DTE, up to 115.2 kbps); 1x 10Base-T Ethernet port; 1x SCSI-2 interface (DMA, up to 10 MB/s) |

| Digital I/O Channels | 16 discrete channels (8 input, 8 output); TTL/CMOS compatible (5 VDC logic) |

| Bus Standard | VMEbus 3.0 compliant (32-bit address/data bus); master/slave mode; 4-level bus arbitrator |

| Physical Dimensions | Standard 3U VME form factor (100 mm × 160 mm × 16 mm; L×W×H) |

| Power Requirements | +5 VDC (2.2 A typical, 2.8 A maximum); ±12 VDC (0.6 A typical each) |

| Operating Temperature Range | 0°C – 60°C (32°F – 140°F); Storage: -20°C – 70°C (-4°F – 158°F) |

| Compliance Standards | FCC Class A (EMI), CE, RoHS, IEC 61000-6-2 (Industrial EMC Immunity), UL 508, IEEE 802.3 |

| On-Board Features | ECC error correction; hardware watchdog timer; EEPROM for system configuration; per-interface status LEDs (serial/Ethernet/SCSI/I/O); on-board diagnostic firmware |

| Compatibility | Works with legacy Motorola VME I/O modules (e.g., Motorola MVME-050, Motorola MVME-705-1); supports SCSI-2 storage, Ethernet SCADA, and TTL/CMOS sensors |

MOTOROLA MVME-167-32B

Product Introduction

The Motorola MVME-167-32B is a legacy high-performance SBC from Motorola’s MVME-167 series, engineered to deliver robust processing power and data integrity for mid-scale VMEbus-based automation systems. As a 3U VME device, it sits above entry-level controllers like the Motorola MVME-201 and mid-tier SBCs like the Motorola MVME712-101, offering ECC DRAM, a faster MC68040 processor, and integrated I/O—making it ideal for data-intensive tasks that demand precision and reliability.

In automation architectures, the Motorola MVME-167-32B acts as a “premium processing hub”: its ECC DRAM ensures error-free storage of critical data (e.g., batch recipes, sensor histories), while the MC68040’s FPU handles complex calculations like PID control or predictive maintenance algorithms. For example, in a regional pharmaceutical plant, the Motorola MVME-167-32B can monitor 8 bioreactors (via serial-connected sensors), run pH adjustment calculations (using the FPU), and store 6 months of batch data on a SCSI hard drive—all without performance bottlenecks. Today, it remains indispensable for maintaining legacy systems in sectors like biotech, semiconductor manufacturing, and power grid monitoring, where data accuracy and processing speed are mission-critical.

Core Advantages and Technical Highlights

ECC DRAM for Uncompromised Data Integrity: The Motorola MVME-167-32B’s 32 MB ECC DRAM corrects single-bit errors and detects multi-bit errors— a critical feature missing from entry-level models like the Motorola MVME-201. In a semiconductor fab, this means the Motorola MVME-167-32B retains accurate wafer etching parameters even in high-electromagnetic-interference (EMI) environments, preventing costly rework due to data corruption. This capability reduces data-related downtime by 50%, ensuring compliance with strict industry quality standards.

33 MHz MC68040 Processor with FPU for Complex Tasks: The Motorola MVME-167-32B’s MC68040 processor (with integrated FPU) delivers 2x faster instruction execution and 3x faster floating-point calculations than the MC68000 in the Motorola MVME-201. In a power plant’s turbine control system, this speed lets the Motorola MVME-167-32B process 1,000+ voltage/current sensor readings per second, calculate load balancing adjustments, and transmit alerts via Ethernet—all within 50 ms latency. The FPU also eliminates the need for external coprocessors, reducing chassis slot usage and wiring complexity.

Integrated I/O + High-Speed Interfaces for All-in-One Control: Unlike SBCs requiring add-on modules, the Motorola MVME-167-32B integrates 16 digital I/O channels, SCSI-2, and Ethernet in one slot. In a biotech lab’s cell culture system, this means the Motorola MVME-167-32B can control incubator temperatures (digital outputs), monitor CO₂ levels (digital inputs), store growth data on a SCSI drive, and share real-time metrics with researchers via Ethernet—no extra hardware needed. The 10 MB/s SCSI DMA also speeds up data transfers, critical for backing up large volumes of experiment data.

Typical Application Scenarios

The Motorola MVME-167-32B excels in data-intensive, precision-critical industrial tasks. In a regional semiconductor packaging plant (paired with Motorola MVME-705-1 for extra serial ports), the Motorola MVME-167-32B manages 10 packaging machines: its ECC DRAM stores wafer ID and test data, the FPU calculates bonding pressure parameters, 16 digital I/O channels control machine relays, and Ethernet sends production logs to a factory MES system. The module’s 0°C–60°C operating range withstands cleanroom temperature fluctuations, while ECC DRAM resists EMI from nearby robotic arms—preventing data corruption that would ruin $10k+ wafers.

In a municipal water treatment plant’s chemical dosing system, the Motorola MVME-167-32B controls 6 dosing pumps: its serial ports connect to pH/conductivity sensors, the FPU calculates chemical doses (adjusting for water flow), SCSI stores 12 months of dosing logs, and digital outputs activate pumps. The battery-backed SRAM retains dosing recipes during power outages, while the watchdog timer triggers a safe shutdown if sensors disconnect—avoiding over-dosing that would contaminate water supplies. For the plant, the Motorola MVME-167-32B avoids the $80k cost of upgrading to a modern PLC, as it still meets EPA monitoring requirements.

Related Model Recommendations

Motorola MVME-167-16A: Lower-Memory Sibling. 16 MB ECC DRAM variant of Motorola MVME-167-32B; cost-effective for less data-intensive tasks (e.g., basic factory control).

Motorola MVME-201: Entry-Level Controller. Budget alternative to Motorola MVME-167-32B for simple I/O control (e.g., auxiliary pumps) where high performance isn’t needed.

Motorola MVME-705-1: Serial Communication Module. Complements Motorola MVME-167-32B by adding 8 serial ports (e.g., connecting more sensors in semiconductor plants).

Motorola MVME-050: Digital I/O Module. Expands Motorola MVME-167-32B’s I/O to 32 channels (e.g., controlling extra pumps in water treatment plants).

Emerson RSTi-EP CPE300: Modern Replacement. Replaces Motorola MVME-167-32B in Ethernet migrations; offers Gigabit Ethernet, 4 GB RAM, and legacy VME I/O compatibility.

Seagate ST34573N: SCSI-2 Hard Drive. Accessory for Motorola MVME-167-32B; 4.5 GB capacity for long-term data storage (e.g., semiconductor production logs).

Motorola FLN4234A: Ethernet Gateway. Bridges Motorola MVME-167-32B to cloud platforms; transmits SCSI-stored data for remote power plant monitoring.

Phoenix Contact RS-485 Repeater: Signal Booster. Extends Motorola MVME-167-32B’s serial range (via Motorola MVME-705-1) to 2 km (e.g., large water treatment campuses).

MOTOROLA MVME-167-32B

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing Motorola MVME-167-32B, power off the VME chassis and verify compatibility with ±12 VDC (0.6 A max) and +5 VDC (2.8 A max) to prevent electrical damage. Use an anti-static wristband and mat to protect the processor and ECC DRAM from ESD. Gather tools: Phillips screwdriver (chassis mounting), Cat5 Ethernet cable, terminated SCSI-2 cable, torque wrench (0.5–0.8 N·m for terminals), and a serial terminal (for EEPROM configuration). Avoid installing near high-EMI sources (e.g., variable-frequency drives, high-voltage lines) to prevent Ethernet/SCSI signal interference.

Maintenance suggestions: Monthly, inspect Motorola MVME-167-32B’s LEDs—steady green ECC “OK” LED confirms no memory errors; blinking Ethernet “activity” LED indicates data transfer. Quarterly, clean the VME connector with compressed air (low pressure) to remove dust. Every 2 years, replace the TOD clock/SRAM backup battery (3V lithium) and run ECC DRAM self-tests via diagnostic firmware. If SCSI transfers slow, check cable termination (120Ω at end devices); if I/O channels fail, use the on-board debugger to isolate faults. Store a backup EEPROM with system configurations to minimize downtime during replacement.

Service and Guarantee Commitment

We back Motorola MVME-167-32B with a 120-day warranty for all refurbished units—longer than standard 90-day warranties—covering defects in ECC DRAM, processor/FPU performance, and interface functionality. Each unit undergoes rigorous testing: 24-hour ECC error validation (10,000 simulated single-bit errors), SCSI data transfer (10 MB/s, zero packet loss), and temperature cycling (0°C–60°C) to meet original Motorola standards.

Our 24/7 technical support team provides guidance on Motorola MVME-167-32B installation, ECC configuration, and integration with legacy VME modules (e.g., Motorola MVME-050). We offer customized maintenance plans: quarterly remote diagnostic checks (via Ethernet) and semi-annual on-site ECC testing. Our spare parts inventory includes critical components (MC68040 processors, ECC DRAM chips) for fast repairs. For users modernizing to Ethernet, we provide free consultation to pair Motorola MVME-167-32B with Emerson’s RSTi-EP gateways, ensuring seamless legacy I/O integration.