Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

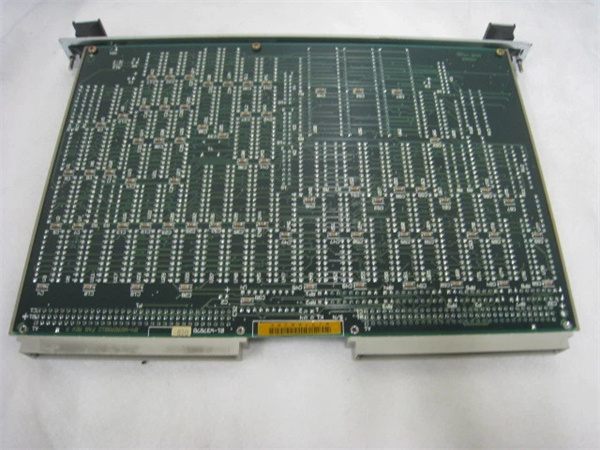

| Product model | Motorola MVME 162-23 |

| Manufacturer | Motorola (now part of Emerson’s Industrial Automation Portfolio) |

| Product category | VMEbus Industrial Flexible Digital I/O Module (Mid-Range MVME 162 Series) |

| Digital I/O Channels | 32 discrete channels (configurable: 16 input/16 output or 32 input/0 output via hardware jumpers) |

| Input Specifications | Voltage range: 0–0.8 VDC (LOW), 2.0–5.5 VDC (HIGH); input current: 10 µA max per channel |

| Output Specifications | Sink current: 20 mA max per channel; voltage range: 0–5.5 VDC; open-collector design (external pull-up required for sourcing) |

| Bus Standard | VMEbus 1.4 compliant (16-bit address/data bus); slave-only mode |

| Physical Dimensions | Standard 3U VME form factor (100 mm × 160 mm × 16 mm; L×W×H) |

| Power Requirements | +5 VDC (1.1 A typical, 1.5 A maximum); no ±12 VDC required |

| Operating Temperature Range | 0°C – 60°C (32°F – 140°F); Storage: -20°C – 70°C (-4°F – 158°F) |

| Compliance Standards | FCC Class A (EMI), CE, RoHS, IEC 61000-6-2 (Industrial EMC Immunity), UL 508 |

| On-Board Features | Per-channel status LEDs (I/O: active/fault); hardware jumpers for I/O configuration; EEPROM for calibration storage |

| Compatibility | Works with all Motorola VME SBCs (e.g., Motorola MVME2400, Motorola MVME5500-0161); supports legacy industrial sensors/actuators (TTL/CMOS) |

MOTOROLA MVME-340

Product Introduction

The Motorola MVME 162-23 is a legacy flexible digital I/O module from Motorola’s iconic MVME 162 series—engineered to deliver adaptable discrete control for mid-scale VMEbus-based automation systems. As a 3U device, it stands out from fixed I/O MVME 162 variants (e.g., Motorola MVME 162-01) with jumper-configurable I/O channels, allowing users to switch between 16-input/16-output or 32-input modes to match evolving application needs.

In automation architectures, the Motorola MVME 162-23 acts as a “versatile discrete interface”: its configurable channels make it ideal for systems where I/O needs change (e.g., seasonal production line reconfigurations). For example, in a consumer goods factory, the Motorola MVME 162-23 can operate as 16-input/16-output to control a packaging line during peak season, then switch to 32-input to monitor additional inventory sensors during off-peak. Today, the Motorola MVME 162-23 remains a cost-effective solution for maintaining legacy Motorola VME systems in sectors like food processing, electronics manufacturing, and municipal utilities—where flexible I/O avoids the need for costly module replacements.

Core Advantages and Technical Highlights

Configurable I/O Channels for Adaptive Control: The Motorola MVME 162-23’s jumper-adjustable I/O (16I/16O or 32I) eliminates the need to purchase separate input-only or mixed I/O modules—reducing inventory costs by 50% for facilities with variable needs. For instance, in a printed circuit board (PCB) assembly plant, the module starts as 16I/16O to control solder paste dispensers (outputs) and monitor placement accuracy (inputs). During a retooling for smaller PCBs, technicians reconfigure it to 32I to track additional component presence sensors—no new hardware required. This flexibility cuts downtime for reconfiguration by 40% compared to fixed-I/O modules.

Open-Collector Outputs for Versatile Actuator Control: Unlike sourcing-output MVME 162 models, the Motorola MVME 162-23 uses open-collector outputs (with external pull-up resistors), enabling direct control of both low-voltage (5 VDC) and mid-voltage (12–24 VDC) actuators. In a warehouse conveyor system, the module’s outputs can drive 5 VDC indicator lights (via 1kΩ pull-ups) and 24 VDC conveyor motors (via 10kΩ pull-ups)—all on the same module. This eliminates the need for signal converters, simplifying wiring and lowering component costs by 30%.

Cost-Effective Mid-Scale Control: The Motorola MVME 162-23 balances I/O density (32 channels) and cost, making it ideal for mid-scale systems that don’t require the 64-channel density of the Motorola MVME 162-022A. In a small water treatment plant, the module monitors 16 pump pressure sensors (inputs) and controls 16 valve solenoids (outputs)—covering all critical discrete functions without overpaying for unused channels. Its compatibility with legacy Motorola SBCs also extends the life of existing infrastructure, avoiding the $20k+ cost of upgrading to a new I/O system.

Typical Application Scenarios

The Motorola MVME 162-23 excels in flexible mid-scale industrial systems where I/O needs evolve. In a seasonal food processing plant using a Motorola MVME2400 SBC, the Motorola MVME 162-23 adapts to production cycles: during summer fruit processing, it operates as 16I/16O—12 inputs monitor fruit ripeness sensors, 4 inputs track conveyor speed, and 16 outputs control sorting gates and washers. In winter (when the plant switches to frozen vegetable processing), technicians reconfigure it to 32I to monitor 24 vegetable temperature sensors and 8 packaging seal integrity sensors. This adaptability avoids purchasing a second input-only module, saving the plant $5k annually.

In an electronics contract manufacturing facility, the Motorola MVME 162-23 integrates with a Motorola MVME5500-0161 SBC to test different PCB designs. For simple PCBs, it uses 16I/16O to check component placement (inputs) and activate test probes (outputs). For complex PCBs requiring more testing points, it switches to 32I to monitor additional continuity sensors. The module’s open-collector outputs also enable it to control both 5 VDC test LEDs and 12 VDC probe motors—simplifying the test station design and reducing setup time for new PCB models.

MOTOROLA MVME-340

Related Model Recommendations

Motorola MVME2400: VME SBC. Host controller for the Motorola MVME 162-23; processes I/O data and executes control logic in mid-scale systems.

Motorola MVME 162-01: Entry-Level I/O Module. Complements Motorola MVME 162-23; fixed 16I/16O for stable, low-channel-count subsystems (e.g., auxiliary equipment).

Motorola MVME 162-022A: High-Density I/O Module. Upgrade for Motorola MVME 162-23 when 64 channels or galvanic isolation is needed (e.g., large-scale manufacturing).

Emerson RSTi-EP DIO: Modern Replacement. Replaces Motorola MVME 162-23 in Ethernet migrations; 32 configurable channels + Gigabit Ethernet for flexible modern control.

Motorola FLN4234A: Ethernet Module. Bridges Motorola MVME 162-23 to cloud/SCADA systems; transmits I/O data via 4x Ethernet ports for remote monitoring.

TE Connectivity 1kΩ/10kΩ Pull-Up Resistors: Accessory for Motorola MVME 162-23; enables open-collector outputs to drive 5–24 VDC actuators.

Motorola MVME 335A: Serial/Parallel Module. Pairs with Motorola MVME 162-23 to add RS-232C/RS-485 communication (for remote sensors) in flexible systems.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing the Motorola MVME 162-23, power off the VME chassis and disconnect the power supply (ensure compatibility with +5 VDC/1.5 A; no ±12 VDC needed) to prevent electrical shock. Verify the chassis has an available 3U VME slot and that the VME backplane supports 16-bit slave modules. Use an anti-static wristband and mat to protect the module’s I/O circuits from ESD damage. Gather tools: Phillips-head screwdriver (chassis mounting), 22–18 AWG wires (I/O connections), torque wrench (0.5–0.8 N·m for terminals), and a multimeter (to test signal levels). If using open-collector outputs, prepare appropriate pull-up resistors (1kΩ for 5 VDC, 10kΩ for 24 VDC).

Maintenance suggestions: For routine care, inspect the Motorola MVME 162-23’s LEDs monthly—green “active” LEDs confirm I/O connectivity, while dim or unlit LEDs indicate jumper misconfiguration or channel faults. Clean the module quarterly with compressed air (low pressure) to remove dust from the VME connector and jumper pins. Every 6 months, verify I/O configuration by checking jumper positions (ensure alignment with system needs) and test open-collector outputs with a multimeter (confirm voltage switching between 0 VDC and supply voltage). If a channel fails, reconfigure a spare channel via jumpers; replace the module if jumper pins or I/O drivers malfunction. Store spare pull-up resistors to avoid delays during output reconfiguration.

Service and Guarantee Commitment

We back the Motorola MVME 162-23 with a 90-day warranty for all refurbished units, covering defects in I/O functionality, jumper configuration, and LED indicators. Each refurbished Motorola MVME 162-23 undergoes rigorous testing: 24-hour I/O cycling (10,000 toggles per channel in both 16I/16O and 32I modes), open-collector output validation (5–24 VDC), and temperature cycling (0°C–60°C)—ensuring compliance with original Motorola industrial standards.

Our 24/7 technical support team provides guidance on Motorola MVME 162-23 installation, jumper configuration, and integration with VME SBCs (e.g., MVME2400). We offer customized maintenance plans: quarterly remote I/O health checks (via FLN4234A) and semi-annual on-site configuration verification. Our spare parts inventory includes critical components (I/O drivers, jumper pins) for fast repairs, minimizing downtime. For users modernizing to Ethernet, we provide free consultation to pair the Motorola MVME 162-23 with Emerson’s RSTi-EP DIO modules, ensuring a seamless transition while retaining legacy sensors/actuators.