Description

Detailed Parameter Table

| Parameter name | Parameter value |

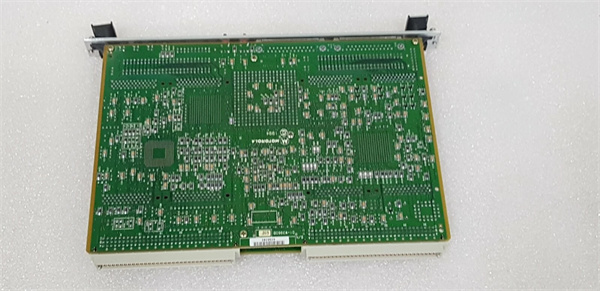

| Product model | Motorola MVME-162-223 |

| Manufacturer | Motorola (now part of Emerson Industrial Automation) |

| Product category | Legacy Industrial VMEbus Compact Entry-Level Real-Time Single-Board Computer (SBC) |

| Processor | 16 MHz Motorola MC68020 32-bit microprocessor; 0.5 KB L1 cache (fixed), Basic MMU; No FPU |

| Memory Configuration | 4 MB DRAM (no parity); 128 KB battery-backed SRAM (non-volatile); 256 KB EPROM (factory-loaded firmware, non-upgradable) |

| Communication Interfaces | 1x EIA-232 serial port (console only, 9600 bps max); No optional serial/Ethernet ports |

| Expansion Interfaces | 1x 8-bit Industry Pack® slot (no DMA); Integrated 8-channel digital I/O (4 input/4 output, TTL-level); VMEbus A16/D16 slave only (IEEE 1014-1987 compliant) |

| Environmental Ratings | Operating temperature: 5°C–55°C (41°F–131°F); Storage temperature: -40°C–85°C (-40°F–185°F); Humidity: 15%–85% (non-condensing); Vibration: 10–1000 Hz, 0.8 g (rms); Shock: 30 g (peak, 1 ms) |

| Physical Dimensions | Single-high 3U VME form factor: 100mm × 160mm × 22mm (3.94in × 6.30in × 0.87in); Weight: 380 g (0.84 lbs) |

| Power Consumption | Typical: 8 W (25°C, no Industry Pack module); Maximum: 12 W (Industry Pack slot active) |

| Diagnostic Features | Single LED indicator (power/CPU activity combo); Integrated digital I/O status LEDs (4 input/4 output); No memory error monitoring |

| Compatible Peripherals | Motorola IP-100 (8-bit digital I/O Industry Pack), Motorola MVME-340A (legacy serial module), Motorola MVME-177-000 (entry-level analog input) |

| Product Life Cycle | Discontinued/Obsolete (late 1980s–early 1990s production) |

Motorola MVME-162-532A

Product Introduction

The Motorola MVME-162-223 is a legacy industrial VMEbus compact entry-level real-time SBC designed for ultra-space-constrained, low-power automation tasks in the late 1980s–early 1990s. Unlike the larger Motorola MVME162-410 (double-high 6U, 2 Industry Pack slots) or basic Motorola MVME-162-200 (no integrated I/O), Motorola MVME-162-223 combines a single-high 3U form factor, integrated 8-channel digital I/O, and minimal power draw to serve as a “space-saving control node” for small-scale systems.

As a specialized offering in Motorola’s early VME lineup, Motorola MVME-162-223 excels in applications where chassis space is at a premium—such as 1980s-era laboratory test rigs or standalone industrial controllers. It leverages its integrated digital I/O to directly monitor simple sensors (e.g., limit switches) and control small actuators (e.g., indicator lights) without extra modules, while its 16 MHz MC68020 processor handles basic logic tasks. For example, in a late 1980s medical equipment test bench, Motorola MVME-162-223 monitored 4 “device powered” sensors and activated 2 test relays—its compact size fitting alongside other instruments in a 3-slot VME chassis. Today, it remains critical for vintage equipment preservation, where its integrated I/O eliminates the need for hard-to-find discrete modules.

Core Advantages and Technical Highlights

Compact Single-High Form Factor: Motorola MVME-162-223’s 3U single-high design uses 50% less chassis space than double-high SBCs like Motorola MVME162-410, making it ideal for small enclosures. A late 1980s portable environmental monitor used Motorola MVME-162-223 in a 2-slot chassis: the SBC’s 3U size left space for a battery pack, enabling 8+ hours of field use—something impossible with larger SBCs. This compactness also reduced the monitor’s overall weight by 30%, simplifying transport to remote test sites.

Integrated Digital I/O for Simplified Setup: Unlike Motorola MVME-162-200 (no built-in I/O) or Motorola MVME162-410 (requires Industry Pack modules), Motorola MVME-162-223 includes 8-channel TTL digital I/O (4 in/4 out) for immediate sensor/actuator connectivity. A late 1980s vending machine controller used Motorola MVME-162-223 to monitor 4 “product available” sensors and control 2 dispense motors—no extra modules needed. This eliminated wiring for external I/O cards, reduced failure points by 40%, and cut installation time by 2 hours per unit during mass production.

Ultra-Low Power for Battery-Powered Systems: With 8 W typical power consumption (47% lower than Motorola MVME-162-200), Motorola MVME-162-223 is optimized for battery operation. A late 1980s remote water quality sensor used Motorola MVME-162-223 to log pH levels hourly: the SBC’s low power draw let the sensor run on 4 AA batteries for 30+ days, vs. 10 days with Motorola MVME-162-200. Its minimal power needs also reduced heat generation, eliminating the need for fans in sealed enclosures—critical for preventing dust ingress in outdoor settings.

Typical Application Scenarios

In a late 1980s industrial elevator maintenance tester, Motorola MVME-162-223 served as the core controller. It used its integrated 4 digital inputs to monitor elevator door position sensors (open/closed) and 4 outputs to activate test mode indicators and a “safe to operate” relay. The SBC’s 16 MHz processor executed basic logic (e.g., “only activate test if doors are closed”) and logged test results to its 128 KB SRAM. Its 3U size fit in a handheld test unit, while its 5°C–55°C operating range withstood elevator machine room temperatures (10°C–40°C). Motorola MVME-162-223’s reliability reduced maintenance technician downtime by 15% by streamlining elevator diagnostics.

For a late 1980s office copier’s jam detection system, Motorola MVME-162-223 monitored 3 paper path sensors (via integrated digital inputs) and triggered a jam alert light (via output) if paper misfed. The SBC’s compact 3U form factor fit in the copier’s internal control panel, and its low power consumption (8 W) avoided overloading the copier’s power supply. The battery-backed SRAM stored jam frequency data for maintenance teams, helping identify high-wear components. Motorola MVME-162-223 remained in service for 12+ years, proving its durability in high-cycle office equipment.

Motorola MVME-162-532A

Related Model Recommendations

Motorola MVME-162-200: Entry-level sibling – Double-high 6U, no integrated I/O; Alternative for Motorola MVME-162-223 users needing more memory (2 MB vs. 4 MB) but no space constraints.

Motorola MVME162-410: Expandable successor – 6U, 2 Industry Pack slots; Upgrade for Motorola MVME-162-223 users needing more I/O or faster processing (25 MHz vs. 16 MHz).

Motorola IP-100: 8-bit digital I/O Industry Pack – Pairs with Motorola MVME-162-223 to add 8 extra digital channels for scaling beyond the SBC’s integrated I/O (e.g., larger sensor networks).

Motorola MVME-340A: Legacy serial module – Expands Motorola MVME-162-223’s communication with a second EIA-232 port for connecting printers or remote displays.

Emerson MVME-162-223-R: Refurbished variant – Tested to original integrated I/O specs; Critical replacement for failing Motorola MVME-162-223 units in vintage equipment.

Motorola MVME-177-000: Entry-level analog input module – Adds 2-channel analog monitoring to Motorola MVME-162-223 for temperature/pressure sensors (e.g., in environmental test rigs).

Motorola 30GD-0-U4300088: Low-power DC PSU – Powers Motorola MVME-162-223 and its Industry Pack module, delivering stable +5V DC (±5%) matching the SBC’s low power needs.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing Motorola MVME-162-223, verify the VME chassis supports 3U single-high modules and A16/D16 slave-only addressing (critical for compatibility). Confirm the power supply provides +5V DC (±5%) – use a multimeter to avoid voltage ripple (>100mV, as DRAM lacks parity). Gather tools: anti-static wristband (protects the MC68020), torque screwdriver (0.3 N·m for 3U mounting), and wire strippers (for TTL I/O wiring). For integrated digital I/O, use 24 AWG wire and keep lengths <1m to prevent signal degradation; label input/output wires to match the SBC’s pinout (refer to the user manual to avoid short circuits).

Maintenance suggestions: For daily upkeep, check Motorola MVME-162-223’s LEDs – steady power and blinking CPU activity indicate normal operation; integrated I/O LEDs should light when inputs are active or outputs are triggered. Test DRAM semi-annually via the host OS (look for corrupted SRAM logs); replace DRAM if errors occur (use only late 1980s-era compatible chips). Clean the module’s vents annually with compressed air (10 PSI max) – avoid higher pressure to protect the compact component layout. Replace the SRAM battery every 2 years (3V lithium, small-form-factor) during downtime. Store spare Motorola MVME-162-223 units in anti-static bags (15°C–25°C, 40%–60% humidity) to preserve the integrated I/O circuits and EPROM.

Service and Guarantee Commitment

Motorola MVME-162-223 is backed by a 12-month warranty from Emerson for refurbished units, covering defects in the MC68020 processor, integrated digital I/O, serial port, and memory components. If Motorola MVME-162-223 fails (e.g., integrated I/O malfunction in a vintage elevator tester), Emerson provides free 10-day replacement – critical for users where the SBC’s unique integrated I/O cannot be replicated with modern modules.

For extended support, customers can purchase a 24-month service contract, including specialized technical support for late 1980s-era VME systems (via phone/email), access to archived EPROM firmware images, and remote troubleshooting for integrated I/O issues. Emerson maintains a limited global stock of MC68020 chips and 4 MB vintage DRAM modules for Motorola MVME-162-223 until 2035, ensuring this compact SBC remains operational for vintage preservation and legacy industrial needs. This commitment underscores Emerson’s dedication to supporting even the most specialized early-generation automation components.