Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | Motorola MVME-147SB-1 |

| Manufacturer | Motorola (now part of Emerson’s Industrial Automation Portfolio) |

| Product category | VMEbus Industrial High-Precision Analog I/O Module (MVME-147 Series) |

| Analog Input Channels | 16 differential channels; 16-bit ADC resolution; sampling rate: 100 kSPS (max) |

| Analog Output Channels | 4 channels; 12-bit DAC resolution; output update rate: 50 kSPS (max) |

| Input Voltage Ranges | Software-selectable: ±5 VDC, ±10 VDC, 0–5 VDC, 0–10 VDC; input impedance: 10 MΩ |

| Output Voltage Ranges | Software-selectable: ±5 VDC, ±10 VDC, 0–5 VDC, 0–10 VDC; max current: 20 mA |

| Bus Standard | VMEbus 1.4 compliant (16-bit address/data bus); slave-only mode |

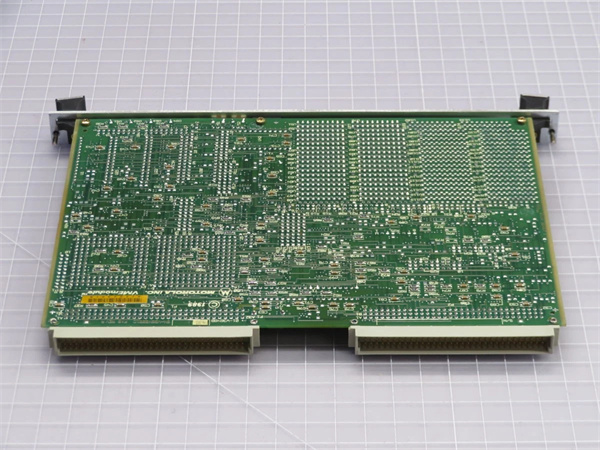

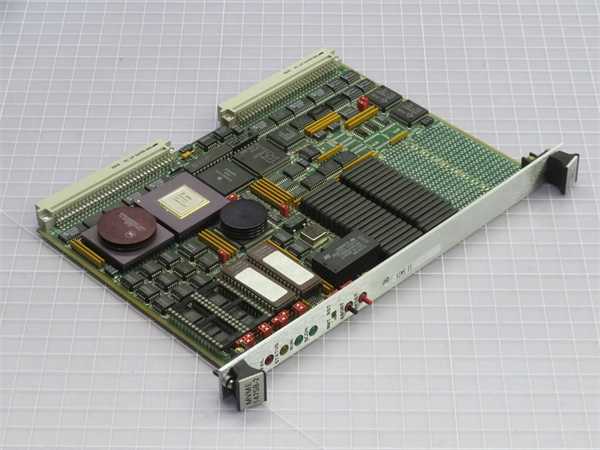

| Physical Dimensions | Standard 3U VME form factor (100 mm × 160 mm × 16 mm; L×W×H) |

| Power Requirements | +5 VDC (1.2 A typical, 1.8 A max); ±12 VDC (0.5 A typical each) |

| Operating Temperature Range | 0°C – 60°C (32°F – 140°F); Storage: -20°C – 70°C (-4°F – 158°F) |

| Compliance Standards | FCC Class A (EMI), CE, RoHS, IEC 61000-6-2 (Industrial EMC Immunity), UL 508 |

| On-Board Features | Per-channel status LEDs (AI: active/fault; AO: ready); EEPROM (calibration data); hardware gain calibration; anti-aliasing filters (AI channels) |

| Accuracy Ratings | AI: ±0.01% full-scale (FS) at 25°C; AO: ±0.05% FS at 25°C |

MOTOROLA MVME-147SB-1

Product Introduction

The Motorola MVME-147SB-1 is a legacy high-precision analog I/O module from Motorola’s iconic MVME-147 series, engineered to deliver accurate signal acquisition and control for demanding industrial process applications. As a 3U VME device, it differentiates itself from entry-level analog modules (e.g., Motorola MVME-400) with 16-bit ADC resolution, 100 kSPS sampling, and software-selectable ranges—filling a critical niche in applications where measurement precision and speed are non-negotiable.

In automation architectures, the Motorola MVME-147SB-1 acts as a “precision signal hub”: its 16 differential analog inputs capture high-fidelity data from sensors (e.g., pressure transducers, thermocouples with signal conditioners), while 4 analog outputs send calibrated control signals to actuators (e.g., proportional valves, variable-speed drives). The module’s anti-aliasing filters and hardware calibration ensure stable measurements even in noisy industrial environments. Today, the Motorola MVME-147SB-1 remains indispensable for maintaining legacy Motorola VME systems in sectors like pharmaceutical manufacturing, semiconductor processing, and aerospace testing—where replacing high-precision analog infrastructure would disrupt tightly controlled processes.

Core Advantages and Technical Highlights

High-Precision 16-Bit ADC for Critical Measurements: The Motorola MVME-147SB-1’s 16-bit analog inputs (±0.01% FS accuracy) deliver 65,536 discrete measurement levels—16x more resolution than 12-bit modules like the Motorola MVME-410. This precision is critical for applications like pharmaceutical batch control, where the module monitors 8 reactor temperature sensors (±0.1°C accuracy) to ensure drug formulation consistency. The 100 kSPS sampling rate also captures fast transient signals, such as pressure spikes in a chemical injection system, preventing missed process anomalies that lead to product defects.

Software-Selectable Ranges for Versatile Sensing: Unlike fixed-range analog modules, the Motorola MVME-147SB-1 supports four software-selectable input/output ranges (±5 VDC, ±10 VDC, 0–5 VDC, 0–10 VDC)—eliminating the need for external signal scalers. In a semiconductor fab, the module uses 0–5 VDC range to measure low-voltage sensor data (e.g., wafer position) and ±10 VDC range for high-voltage equipment feedback (e.g., plasma etcher power)—all in one slot. This flexibility reduces module count by 50% compared to using dedicated range-specific I/O cards.

Robust Signal Conditioning for Noise Immunity: The Motorola MVME-147SB-1’s differential input design and anti-aliasing filters minimize interference from nearby motors, VFDs, or high-voltage lines—common in industrial settings. In a power plant’s turbine control system, the module captures 6 differential pressure signals near 11 kV power lines; differential inputs reject common-mode noise (up to 100 V), while 50 Hz/60 Hz notch filters eliminate line-frequency interference. This ensures measurement errors stay below ±0.01% FS, critical for turbine speed regulation and safety.

Typical Application Scenarios

The Motorola MVME-147SB-1 excels in high-precision process control. In a pharmaceutical manufacturing plant using a Motorola MVME5500-0161 SBC, the Motorola MVME-147SB-1 manages a drug mixing process: 12 analog inputs monitor pH (±0.01 pH) and dissolved oxygen (±0.1 ppm) sensors (using ±5 VDC range), while 3 analog outputs control peristaltic pumps (0–10 VDC range) to adjust chemical dosing. The module’s 0.01% FS accuracy ensures batch-to-batch consistency, meeting FDA regulatory requirements. The anti-aliasing filters also suppress noise from mixing motors, preventing false pH readings that would trigger costly rejections.

In an aerospace component testing lab, the Motorola MVME-147SB-1 integrates with a Motorola MVME2400 SBC to test turbine blades: 8 analog inputs (100 kSPS sampling) capture strain gauge data (±10 VDC range) during vibration tests, while 1 analog output controls a hydraulic actuator (0–5 VDC range) to apply force. The module’s high sampling rate captures transient strain peaks (10 ms duration), while hardware calibration ensures test data accuracy—critical for validating blade durability. For the lab, the Motorola MVME-147SB-1 avoids the $100k cost of upgrading to modern high-speed analog I/O, as it still meets aerospace testing standards.

MOTOROLA MVME-147SB-1

Related Model Recommendations

Motorola MVME5500-0161: High-Performance VME SBC. Host controller for the Motorola MVME-147SB-1; processes high-speed analog data and executes precision control logic.

Motorola MVME-147A: Base MVME-147 Variant. Entry-level analog module; 12-bit ADC (vs. 16-bit in Motorola MVME-147SB-1) for cost-sensitive, lower-precision applications (e.g., HVAC control).

Motorola MVME-162-022A: Digital I/O Module. Complements Motorola MVME-147SB-1; adds 64 discrete channels (for on/off control) in precision process systems (e.g., valve status monitoring).

Emerson RSTi-EP AI/AO Module: Modern Replacement. Replaces Motorola MVME-147SB-1 in Ethernet migrations; 24-bit ADC/16-bit DAC, Gigabit Ethernet, and compatibility with legacy sensors.

Motorola FLN4234A: Ethernet Communication Module. Bridges Motorola MVME-147SB-1 to cloud/SCADA systems; transmits high-precision analog data for remote process monitoring.

Omega DP41-S: Signal Conditioner. Pairs with Motorola MVME-147SB-1; converts thermocouple/RTD signals to 0–10 VDC for direct input to the module (e.g., temperature measurement).

Motorola MVME-374: Multi-Protocol Module. Adds token-bus/RS-485 communication to systems using Motorola MVME-147SB-1; ideal for distributed precision sensor networks.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing the Motorola MVME-147SB-1, power off the VME chassis and verify compatibility with ±12 VDC (critical for analog circuits). Use an anti-static wristband and mat to protect the module’s precision ADC/DAC chips from ESD damage. Gather tools: Phillips screwdriver (chassis mounting), twisted-pair shielded cables (for analog signals), torque wrench (0.5–0.8 N·m for terminals), and a precision multimeter (±0.001 V accuracy for calibration). Avoid installing near high-EMI sources (e.g., welders, VFDs) or heat vents—temperature fluctuations degrade ADC accuracy.

Maintenance suggestions: For routine care, inspect the Motorola MVME-147SB-1’s LEDs monthly—green “active” LEDs confirm AI/AO signal flow, while red “fault” LEDs alert to overrange conditions. Calibrate the module annually using a NIST-traceable voltage source: adjust EEPROM-stored gain offsets via the host SBC to maintain ±0.01% FS accuracy. Clean the module quarterly with compressed air (low pressure) to remove dust from the VME connector and filter vents. If an AI channel drifts beyond specs, replace the anti-aliasing filter capacitor (1 µF, 50 V) with a high-temperature-rated component to restore performance.

Service and Guarantee Commitment

We back the Motorola MVME-147SB-1 with a 120-day warranty for all refurbished units—longer than standard 90-day warranties—covering defects in analog accuracy, sampling rate, and LED indicators. Each refurbished Motorola MVME-147SB-1 undergoes rigorous testing: 24-hour AI sampling (100 kSPS, verifying ±0.01% FS accuracy), AO calibration (±0.05% FS), and temperature cycling (0°C–60°C) to meet original Motorola precision standards.

Our 24/7 technical support team provides guidance on Motorola MVME-147SB-1 installation, calibration, and integration with VME SBCs (e.g., MVME5500-0161). We offer customized maintenance plans: quarterly remote accuracy checks (via FLN4234A) and semi-annual on-site calibration. Our spare parts inventory includes critical components (16-bit ADC chips, anti-aliasing filters) for fast repairs, minimizing downtime in precision-critical systems. For users modernizing to Ethernet, we provide free consultation to pair the Motorola MVME-147SB-1 with Emerson’s RSTi-EP AI/AO modules, ensuring a seamless transition while retaining legacy high-precision sensors.