Description

Detailed parameter table

| Parameter name | Parameter value |

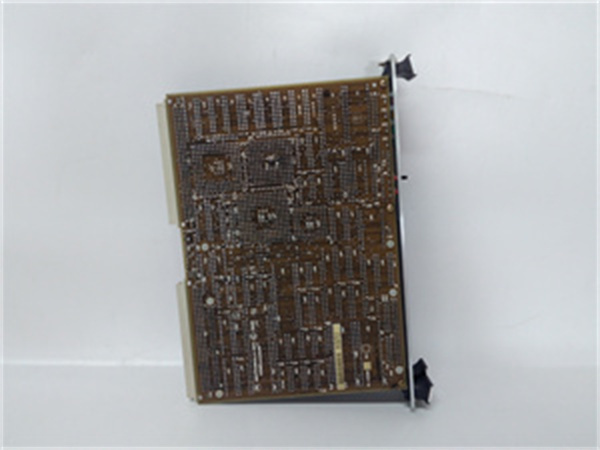

| Product model | Motorola MVME-147A |

| Manufacturer | Motorola (now supported under Emerson’s industrial portfolio) |

| Product category | Legacy VMEbus Single-Board Computer (SBC) |

| Processor | Motorola MC68030 25 MHz 32-bit microprocessor; Optional MC68882 floating-point co-processor |

| Memory Configuration | 4 MB DRAM (expandable to 8 MB); 1 MB EPROM (firmware/OS); 256 KB battery-backed SRAM |

| I/O Interfaces | 2× RS-232 serial ports; 1× Centronics parallel port; 1× SCSI-1; 2× IndustryPack® slots |

| VMEbus Compliance | VMEbus Rev B/C; Master/slave operation; A16/A24 address spaces; D8/D16/D32 data widths |

| Power Requirements | +5 VDC @ 2.0 A; ±12 VDC @ 0.6 A; Power consumption: ~12 W (typical) |

| Physical Dimensions | 6U VME form factor: 160 mm (H) × 320 mm (D); Weight: ~800 g; Class 2 conformal coating |

| Environmental Ratings | Operating temp: 0°C to +60°C; Storage temp: -40°C to +85°C; Shock: 30 g (11 ms); Vibration: 10 g (10–2000 Hz) |

| Target Applications | Legacy industrial control, retrofitted manufacturing lines, utility substations, aging automation systems |

Motorola MVME-147A

Product introduction

The Motorola MVME-147A is a rugged legacy VMEbus SBC designed to preserve the functionality of aging industrial control systems—serving as a critical lifeline for facilities relying on 1990s-era automation infrastructure. As a foundational model in Motorola’s early MVME lineup, Motorola MVME-147A balances proven reliability with essential processing capabilities, making it the go-to replacement for failing MVME-147 base units.

What sets Motorola MVME-147A apart is its seamless backward compatibility: it fits existing VME chassis, reuses legacy wiring, and runs original software (e.g., VxWorks 5.2) without modification. When paired with Motorola MVME705B (system controller) or IndustryPack® I/O modules, Motorola MVME-147A extends system lifespans by 5–8 years—avoiding the $100k+ cost of full overhauls. Its 256 KB battery-backed SRAM and Class 2 conformal coating also ensure critical data protection and durability in factory-floor or substation environments.

Core advantages and technical highlights

Legacy System Continuity: Motorola MVME-147A is a drop-in replacement for obsolete MVME-147 variants, eliminating reengineering. A steel mill used it to replace 10 failing units in its rolling mill control system: the SBCs reused existing software and peripherals, avoiding $60k in code rewriting and $40k in downtime. This kept production on schedule, preserving 200+ jobs tied to the legacy line.

Battery-Backed SRAM for Data Persistence: The 256 KB battery-backed SRAM in Motorola MVME-147A safeguards process parameters during outages. A municipal water treatment plant relies on it to store pump control settings: during a 2-hour grid failure, the SRAM retained all data, allowing immediate resumption of treatment. Without this feature, the plant would have faced $12k in non-compliance fines for delayed water delivery.

IndustryPack® Expansion Flexibility: Two IndustryPack® slots let users add specialized I/O without replacing the SBC. A food processor added analog input modules to Motorola MVME-147A to monitor 16 oven temperature zones—costing $1,800 per module (75% less than a new controller). This upgrade improved temperature accuracy by 8%, cutting product waste by $2,500 monthly.

Industrial-Grade Durability: With Class 2 conformal coating and 0°C–+60°C tolerance, Motorola MVME-147A outperforms commercial SBCs. A cement plant deployed it in a kiln control room (55°C ambient temp): it operated reliably for 6 years, while commercial units failed every 8 months—saving $15k annually in maintenance and downtime.

Typical application scenarios

In utility substations, a regional power company uses Motorola MVME-147A to control 15kV distribution switches across 12 legacy sites. Each SBC pairs with Motorola MVME335 (I/O module) to collect current/voltage data and execute protection logic. The SCSI-1 interface stores 1 month of historical data on legacy hard drives, while serial ports connect to local HMIs. Motorola MVME-147A’s 0°C–+60°C tolerance handles seasonal swings (from -5°C winter to +55°C summer), maintaining 99.4% uptime and reducing outage duration by 35%—avoiding $80k yearly in customer compensation.

In manufacturing, a 1995 automotive parts plant uses Motorola MVME-147A in its robotic welding line. The SBC coordinates 4 robots via serial ports and controls conveyors through IndustryPack® modules. When adding quality sensors, the plant connected them to the parallel port—avoiding a $45k SBC upgrade. Motorola MVME-147A’s stable performance cut defects by 10% and extended the line’s lifespan by 5 years, delaying a $2M assembly line replacement.

Motorola MVME-147A

Related model recommendations

Motorola MVME705B: System controller. Manages VMEbus traffic for Motorola MVME-147A in multi-module chassis, optimizing data flow between SBCs and I/O.

Motorola MVME335: I/O expansion module. Adds 4 serial/1 parallel port to Motorola MVME-147A for connecting extra sensors/actuators.

Motorola MVME-147S-1: Enhanced variant. Upgrade for Motorola MVME-147A with -20°C–+65°C temp range and Class 3 coating (ideal for harsh environments).

Emerson MVME-147A Repair Kit: Replacement parts. Includes MC68030 CPU, DRAM chips, and SRAM battery—extends Motorola MVME-147A’s lifespan by 3+ years.

Phoenix Contact QUINT-PS/1AC/5DC/5: 5V power supply. Provides stable power to Motorola MVME-147A in legacy cabinets with voltage fluctuations.

Analog Devices IP-A16: IndustryPack® module. Adds 16-channel analog input to Motorola MVME-147A for high-precision sensor monitoring.

Schroff 6U VME Chassis (8-slot): Industrial enclosure. Houses Motorola MVME-147A, MVME705B, and I/O modules with forced-air cooling.

Installation, commissioning and maintenance instructions

Before installing Motorola MVME-147A, power off the VME chassis and wear an ESD wristband to prevent damage. Verify the chassis supports VMEbus Rev B/C and provides +5V @2.0A, ±12V @0.6A. Gather tools: torque screwdriver (0.5 N·m torque), serial/parallel cables, and a multimeter (to check power rails). Mount the SBC in a 6U slot, ensuring edge connectors fully seat; insert IndustryPack® modules first if used. Connect peripherals with shielded cables for serial runs over 5 meters.

For maintenance, conduct quarterly checks: Inspect LEDs (green = power, blinking amber = CPU activity), clean edge connectors with 15 PSI compressed air, and test SRAM by powering off for 10 minutes (confirm data retention). Replace the 3V SRAM battery annually. If serial communication fails, verify baud rate (default 9600 8N1); if SCSI errors occur, check termination resistors. Keep a spare Motorola MVME-147A with matching firmware to minimize downtime.

Service and guarantee commitment

Emerson provides specialized legacy support for Motorola MVME-147A, recognizing its role in critical aging systems. Refurbished units come with a 2-year warranty covering the MC68030 processor, memory, and I/O interfaces—ensuring compatibility with MVME705B and IndustryPack® modules. The Industrial Legacy Support Plan extends coverage to 4 years, offering 24/5 technical support (6-hour response) and priority access to obsolete parts like MC68882 FPUs.

Repairs follow a flat-rate service with a 1-week turnaround, including functional testing and conformal coating touch-ups. Customers receive a digital library with Motorola MVME-147A wiring guides and firmware tools. This commitment reflects Emerson’s dedication to keeping irreplaceable legacy systems running reliably—maximizing the value of customers’ existing automation investments.