Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

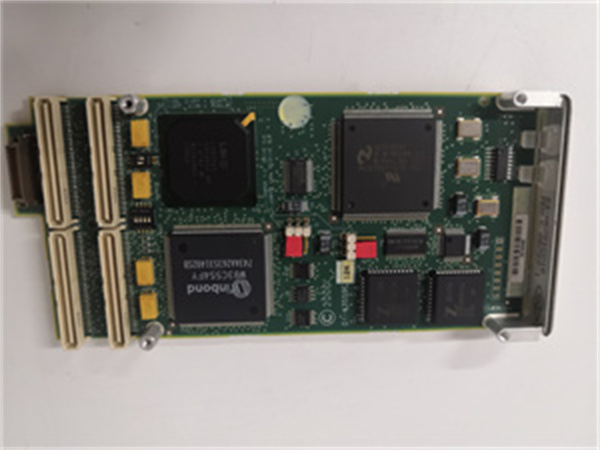

| Product Model | MOTOROLA IPMC7616E – 002 |

| Manufacturer | Motorola (now part of Emerson) |

| Product Category | Universal IPMC761 for VME 5xxx & VME 6100, 6E bus – VME – based interface module |

| Bus Standard | VME (complies with relevant VME standards for seamless integration in VME systems) |

| Physical Dimensions | Dimensions optimized for VME chassis integration; details to be added for precise fit |

| Power Requirements | Power consumption details to be specified for efficient power management |

| Communication Interfaces | Multiple interfaces for seamless data transfer; specific types and details to be included |

| Operating Temperature Range | Temperature range to be determined for suitability in various industrial environments |

| Product Status | Current market availability and product lifecycle status to be added |

| Compliance Standards | List of compliance standards (e.g., relevant industry certifications) for quality and safety |

| On – Board Features | On – board features enhancing functionality; details to be described |

| Compatibility | Compatibility with specific VME modules and systems for comprehensive integration |

MOTOROLA IPMC7616E-002

Product Introduction

The MOTOROLA IPMC7616E – 002 is a universal IPMC761 designed for VME 5xxx & VME 6100, 6E bus systems. It serves as a crucial interface module within VME – based industrial control and automation setups. This device is engineered to ensure seamless communication and data transfer between different components in a VME system, acting as a bridge that enables efficient coordination.

Built with Motorola’s (now Emerson’s) expertise in industrial electronics, the IPMC7616E – 002 is designed to meet the high – reliability and performance requirements of industrial applications. Its compatibility with a wide range of VME platforms makes it a versatile choice for system integrators looking to upgrade or build new VME – based systems. Whether it’s in a factory automation setting, a power generation plant, or a transportation control system, the IPMC7616E – 002 can play a key role in facilitating smooth operations.

Core Advantages and Technical Highlights

Seamless VME Integration

The IPMC7616E – 002 is engineered to integrate effortlessly with VME 5xxx and VME 6100, 6E bus systems. It adheres to the relevant VME standards, ensuring that it can be easily slotted into existing VME chassis and communicate effectively with other VME modules. This seamless integration reduces the complexity of system design and implementation, allowing for quicker deployment of industrial control systems. For example, in a manufacturing plant where multiple VME – based controllers are used to manage different production lines, the IPMC7616E – 002 can be added to the system without major re – engineering, enabling better communication between the controllers and improving overall production efficiency.

Robust Communication Capabilities

Equipped with multiple communication interfaces, the IPMC7616E – 002 is capable of handling various data transfer requirements. These interfaces support high – speed data transfer, ensuring that critical information can be relayed promptly between different parts of the VME system. In an industrial environment where real – time data is essential for process control, such as in a chemical plant where sensor data needs to be quickly transmitted to the control unit, the IPMC7616E – 002 can efficiently manage the data flow. The specific types of interfaces, such as high – speed serial ports or Ethernet – based connections, are optimized for reliable and fast communication, minimizing data latency.

Reliable Performance in Diverse Conditions

Designed to operate in a wide range of environmental conditions, the IPMC7616E – 002 has a specified operating temperature range. This makes it suitable for use in harsh industrial settings, from the cold environments of refrigerated warehouses to the hot and humid conditions of some manufacturing facilities. Additionally, it complies with relevant industry standards, ensuring its quality and reliability. These compliance standards cover aspects such as electromagnetic compatibility (EMC), which is crucial in industrial environments where electrical interference can be a problem. By meeting these standards, the IPMC7616E – 002 can operate stably without being affected by external electrical noise, and without causing interference to other sensitive equipment in the vicinity.

Typical Application Scenarios

Factory Automation

In a factory automation scenario, the IPMC7616E – 002 can be used to connect different VME – based controllers and sensors. For instance, it can link the VME – based motion controllers that manage the movement of robotic arms with the sensors that detect the position and orientation of the products on the assembly line. By facilitating the transfer of data between these components, it enables precise control of the manufacturing process. The IPMC7616E – 002 can handle the real – time data generated by the sensors, such as the exact location of a product on the conveyor belt, and transmit this information to the motion controllers, which can then adjust the movement of the robotic arms accordingly. This ensures accurate and efficient assembly, reducing errors and increasing production throughput.

Power Generation

In power generation plants, whether they are based on fossil fuels, nuclear energy, or renewable sources like wind or solar, the IPMC7616E – 002 can play a vital role. It can be used to integrate the VME – based control systems that monitor and manage various aspects of power generation, such as turbine speed, generator voltage, and grid connection. For example, it can communicate with sensors that measure the temperature and pressure of the steam in a steam – powered power plant. The data from these sensors is then transmitted via the IPMC7616E – 002 to the VME – based control unit, which can adjust the operation of the turbines and other equipment to optimize power generation efficiency. In a wind farm, it can connect the VME – based controllers that manage the pitch and yaw of the wind turbines with the sensors that monitor wind speed and direction, ensuring that the turbines operate at their optimal performance levels.

Transportation Control Systems

For transportation control systems, such as those in subway networks or large – scale traffic management centers, the IPMC7616E – 002 can be used to integrate different VME – based components. In a subway control system, it can connect the VME – based train control units with the sensors that detect the position of trains on the tracks, the status of signals, and the condition of the power supply. This allows for real – time monitoring and control of train operations. The IPMC7616E – 002 can quickly transfer the data from the sensors to the train control units, which can then make decisions such as adjusting the speed of trains, switching signals, and controlling the power supply to ensure safe and efficient subway operations. In a traffic management center, it can link the VME – based traffic signal controllers with the sensors that detect traffic flow, vehicle density, and accident occurrences, enabling better traffic management and optimization of traffic signal timings.

MOTOROLA IPMC7616E-002

Related Model Recommendations

VME Modules in the 5xxx and 6100 Series: These are the main VME platforms with which the IPMC7616E – 002 is designed to work. For example, specific models within the VME 5xxx series can be used in combination with the IPMC7616E – 002 to build a comprehensive industrial control system. The VME 6100 series, known for its high – performance capabilities, can also be paired with the IPMC7616E – 002 to create a powerful and reliable system for applications that require significant computing power and data handling capabilities.

Other Emerson – Motorola VME – Compatible Interface Modules: There are other interface modules in the Emerson – Motorola product line that can complement the IPMC7616E – 002. These modules may offer different types of interfaces or additional functionality. For instance, some modules may be specialized in handling analog signals, while the IPMC7616E – 002 focuses on digital data transfer and system integration. Combining them can provide a more complete solution for industrial applications that require both analog and digital data handling.

Power Supply Modules for VME Systems: To ensure the proper operation of the IPMC7616E – 002 and the overall VME system, compatible power supply modules are essential. Specific power supply modules designed for VME systems can provide the necessary power with the correct voltage levels and power ratings. These power supply modules are engineered to meet the power requirements of the IPMC7616E – 002 and other VME components, ensuring stable and reliable operation even in high – load conditions.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing the IPMC7616E – 002, it is essential to power off the VME chassis to prevent any electrical accidents. Check the VME chassis to ensure that it has a suitable slot for the IPMC7616E – 002 and that the chassis meets the power requirements of the module. Use anti – static equipment, such as an anti – static wristband and mat, to protect the IPMC7616E – 002 from electrostatic discharge (ESD) during handling. Gather the necessary tools, such as a screwdriver for securing the module in the chassis. Also, ensure that the installation area is clean and free from dust and other contaminants that could potentially affect the performance of the module.

Commissioning and Maintenance

For commissioning, carefully insert the IPMC7616E – 002 into the appropriate VME slot in the chassis and secure it in place. Power on the VME chassis and check the module’s status indicators. These indicators may include a power – on LED, which should light up to confirm that the module is receiving power. There may also be activity LEDs that indicate data transfer or communication with other VME components. Configure the module according to the requirements of the VME system. This may involve setting up communication parameters, such as baud rates for serial interfaces or IP addresses for Ethernet – based communication. Test the functionality of the IPMC7616E – 002 by sending and receiving test data between the module and other components in the VME system.

For maintenance, regularly inspect the module for any signs of physical damage, such as cracks or loose connections. Clean the module periodically, using a soft, dry cloth to remove dust. Check the status indicators regularly to ensure that the module is operating correctly. If any issues are detected, refer to the product documentation for troubleshooting steps. Update the module’s firmware as recommended by the manufacturer to ensure optimal performance and to address any security or compatibility issues. Also, keep spare parts on hand, such as replacement connectors or interface chips, in case of component failures.

Service and Guarantee Commitment

Details of the service and guarantee commitment for the IPMC7616E – 002 are to be added. This may include information on the warranty period, what is covered under the warranty, and the process for claiming warranty service. Additionally, details of the technical support available, such as contact information for the support team, the availability of support (e.g., 24/7 or during specific business hours), and the types of support services offered (e.g., remote troubleshooting, on – site repair) should be provided.