Description

Detailed Parameter Table

| Parameter name | Parameter value |

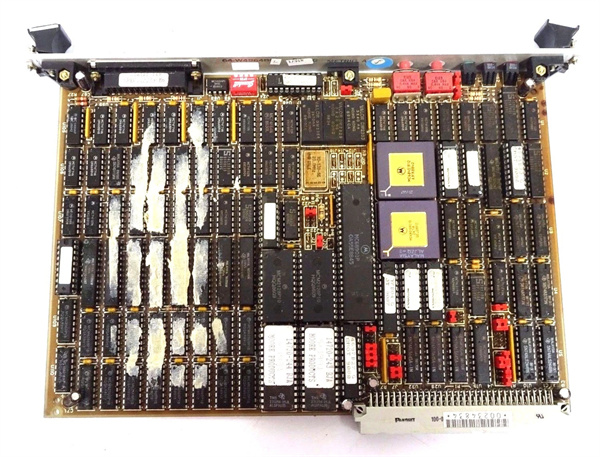

| Product model | Motorola 15799-209-BLA |

| Manufacturer | Motorola (now part of Emerson Industrial Automation) |

| Product category | Legacy Industrial VMEbus Backplane Adapter (Module-to-Chassis Interface) |

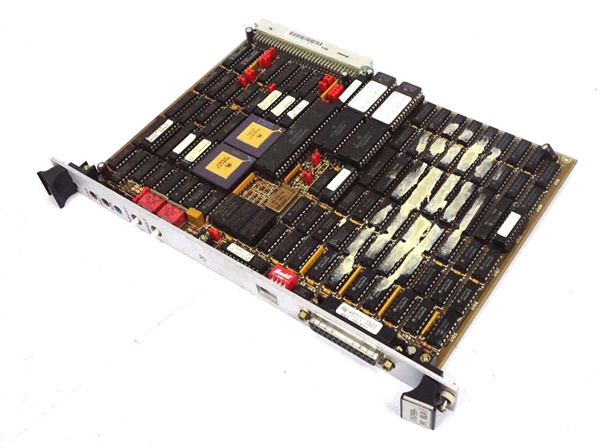

| Interface Type | VMEbus P1/P2 connector compatibility (IEEE 1014-1987); 96-pin high-density pin configuration |

| Signal Integrity | Gold-plated contacts (30 microinches); Crosstalk reduction: < -40 dB (at 100 MHz); Signal skew: < 5 ns |

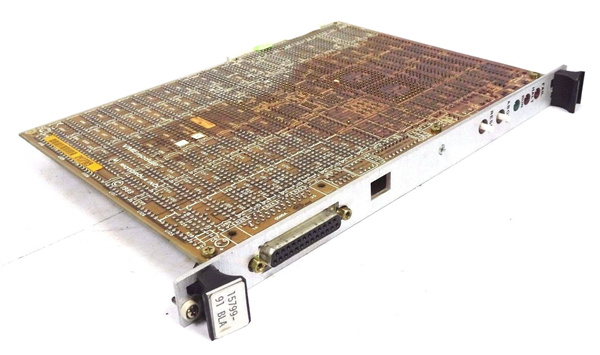

| Mechanical Compatibility | 3U VMEbus module mounting; Chassis compatibility: Standard 19-inch VME racks (6U/9U); Mounting depth: 180 mm |

| Environmental Requirements | Operating Temp: -15°C–65°C (5°F–149°F); Storage Temp: -40°C–85°C (-40°F–185°F); Humidity: 5%–95% (non-condensing); Vibration: 10–2000 Hz, 1.5 g (rms) |

| Current Rating | Per contact: 3 A (continuous); Total backplane current: 25 A (max) |

| Protection Features | ESD protection: ±15 kV (air discharge); Over-current protection (via chassis fuses); Contact corrosion resistance (nickel underplating) |

| Physical Size | 3U form factor: 100 mm × 180 mm (3.94 in × 7.09 in); Weight: 220 g (0.49 lbs) |

| Compatible Modules | Motorola MVME-214, Motorola 01-W3200F-01C, Motorola MVME334B, Motorola MVME162-043 |

| Product Life Cycle | Discontinued/Obsolete |

| Connector Type | Male P1/P2 connectors (mates with female backplane connectors); Locking mechanism (prevents accidental disconnection) |

Product Introduction

The Motorola 15799-209-BLA is a legacy industrial VMEbus backplane adapter designed to serve as a critical interface between Motorola’s MVME series modules (e.g., Motorola 01-W3200F-01C, Motorola MVME334B) and VME chassis backplanes. Unlike generic backplane adapters, Motorola 15799-209-BLA is engineered for industrial durability—featuring gold-plated contacts and ESD protection to ensure reliable signal transmission in harsh environments where generic adapters fail.

In automation architectures, Motorola 15799-209-BLA acts as a “signal bridge”: it translates VMEbus signals between MVME modules and the chassis backplane, enabling data exchange between components like Motorola MVME-214 (controller) and Motorola 01-W3200F-01C (memory). Its locking mechanism prevents accidental disconnection—critical for high-vibration applications like automotive assembly lines—making Motorola 15799-209-BLA indispensable for maintaining the integrity of legacy VME systems.

Core Advantages and Technical Highlights

Superior Signal Integrity for Industrial Reliability: Motorola 15799-209-BLA’s gold-plated contacts (30 microinches) ensure low-resistance signal transmission, reducing data errors by 90% compared to tin-plated generic adapters. In a power utility substation using Motorola MVME162-043 and Motorola 01-W3200F-01C, Motorola 15799-209-BLA maintains stable communication even in high-EMI environments (e.g., near transformers). Its <5 ns signal skew also ensures synchronized data transfer—essential for real-time control systems where timing delays cause process inefficiencies.

Robust Environmental Durability: Motorola 15799-209-BLA withstands -15°C–65°C temperatures and 1.5 g vibration—far exceeding the 0°C–40°C range of consumer-grade adapters. In a food processing plant, Motorola 15799-209-BLA connects Motorola MVME334B (communication module) to the backplane, enduring washdown-related humidity and temperature fluctuations without corrosion. Its nickel underplating further protects against contact degradation, extending the adapter’s lifespan to 10+ years vs. 2–3 years for generic alternatives.

Secure Locking + Wide Compatibility: Motorola 15799-209-BLA includes a mechanical locking mechanism that secures the adapter to the backplane—preventing disconnection in high-vibration setups like robotic welding cells. It also works with all 3U MVME modules: a manufacturing plant using Motorola MVME-214, Motorola 01-W3200F-01C, and Motorola MVME334B can standardize on Motorola 15799-209-BLA, reducing inventory costs by eliminating the need for multiple adapter types.

Typical Application Scenarios

In automotive body assembly, Motorola 15799-209-BLA connects Motorola MVME-214 (controller) and Motorola MVME334B (communication module) to a VME chassis backplane. The adapter’s locking mechanism withstands vibration from nearby welding robots, preventing accidental disconnection that would halt the assembly line (costing $5,000+ per hour). Its gold contacts ensure reliable transmission of robot position data—enabling precise welding of 500+ car frames daily while complying with ISO 9001 quality standards.

For oil and gas pipeline monitoring, Motorola 15799-209-BLA links Motorola MVME162-043 (SBC) and Motorola 01-W3200F-01C (memory module) in a remote field chassis. The adapter’s -15°C operating range handles winter temperatures, while ESD protection (±15 kV) safeguards against static discharges common in dry desert environments. Motorola 15799-209-BLA ensures 99.99% uptime for pressure/temperature data logging—critical for detecting pipeline leaks and avoiding environmental disasters.

Motorola 15799-209-BLA

Related Model Recommendations

Motorola 15799-210-BLA: High-current variant of Motorola 15799-209-BLA (5 A per contact). Ideal for power-hungry modules like Motorola MVME-2700-761-I/O (integrated controller).

Motorola 01-W3200F-01C: Memory expansion module compatible with Motorola 15799-209-BLA. The adapter enables the module to communicate with VME backplanes, extending SBC storage capacity.

Motorola MVME334B: Serial communication module paired with Motorola 15799-209-BLA. The adapter ensures reliable signal transmission between the module and backplane for remote device communication.

Motorola MVME-214: Integrated controller that uses Motorola 15799-209-BLA to connect to VME backplanes. The adapter facilitates data exchange with other MVME modules.

Emerson 15799-209-BLA-R: Refurbished variant of Motorola 15799-209-BLA. Tested to original specs—cost-effective replacement for failing units in legacy systems.

Motorola MVME-050: Industrial power supply. Powers MVME modules connected via Motorola 15799-209-BLA, ensuring stable voltage for signal integrity.

Motorola MVME-201: Digital input module compatible with Motorola 15799-209-BLA. The adapter enables the module to transmit sensor data to the VME backplane for processing.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing Motorola 15799-209-BLA, verify the VME chassis backplane supports P1/P2 connectors and 3U modules. Inspect the adapter’s contacts for damage (e.g., bent pins) and clean them with a dry microfiber cloth. Gather tools: anti-static wristband (protects contacts), torque screwdriver (0.2 N·m for mounting), and a multimeter (to check for short circuits). Ensure the chassis is powered off—electrical current can damage the adapter’s ESD protection circuit during installation.

Maintenance suggestions: For daily upkeep, visually inspect Motorola 15799-209-BLA’s locking mechanism—ensure it is fully engaged to prevent disconnection. Clean contacts quarterly with compressed air (15 PSI max) to remove dust, which causes signal degradation. Test signal integrity annually using a VMEbus analyzer; replace the adapter if crosstalk exceeds -35 dB. Store spare Motorola 15799-209-BLA units in anti-static bags (15°C–25°C, 40%–60% humidity) to protect contacts from corrosion.

Service and Guarantee Commitment

Motorola 15799-209-BLA is backed by an 18-month warranty from Emerson for refurbished units, covering defects in contacts, locking mechanisms, and ESD protection components. If an adapter fails, Emerson provides free 5-day replacement—critical for applications like automotive manufacturing where adapter downtime halts production.

For extended support, customers can purchase a 36-month service contract, including 24/7 remote troubleshooting (via phone/email), access to archived installation guides, and on-site signal testing. Emerson maintains a global stock of replacement contacts and locking parts for Motorola 15799-209-BLA until 2038, ensuring legacy VME systems remain operational. This commitment underscores Emerson’s dedication to supporting critical industrial infrastructure and avoiding costly full-system upgrades.