Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | Motorola 01-W3324F |

| Manufacturer | Motorola (now part of Emerson’s industrial automation portfolio) |

| Product Category | Industrial-Grade Power Distribution Terminal Block / Wiring Interface Accessory (for VMEbus chassis or control cabinets) |

| Physical Dimensions | 75mm × 120mm × 25mm (L×W×H) – compact DIN-rail mountable form factor (compatible with 35mm standard DIN rails) |

| Power Compatibility | Designed for 24V DC industrial power systems (matches Motorola FAB series power supplies like FAB 0340-1049) |

| Terminal Configuration | 12x screw-terminal inputs (24V DC positive/negative); 24x screw-terminal outputs (24V DC, 8A per terminal, 30A total load capacity) |

| Terminal Specifications | Phoenix-style screw terminals (accepts 16–10 AWG stranded/solid copper wires); torque range: 0.6–0.9 N·m; color-coded (red: positive, black: negative) |

| Protection Features | Integrated 30A resettable circuit breaker; reverse polarity protection (prevents damage from wrong wiring); IP20 ingress protection (dust-tight) |

| Operating Temperature Range | -25°C – 75°C (-13°F – 167°F) (extended industrial temperature tolerance for harsh environments) |

| Product Status | Obsolete (discontinued by manufacturer; supported via aftermarket/refurbished services) |

| Compliance Standards | UL 508 (industrial control equipment safety); IEC 60947-1 (low-voltage switchgear); RoHS (environmental compliance); CE Mark |

| Compatibility | Optimized for Motorola VMEbus systems – pairs with power modules (FAB 0340-1049)、distribution boards (30-W2960B01A)、and I/O modules (MVME162-223, MVME172PA-652SE) |

| On-Board Features | LED power status indicator (green: 24V DC present; red: circuit breaker tripped); wire strain relief clips (prevents terminal damage from cable tension); flame-retardant housing (UL94 V-0 rating) |

| Wiring Capacity | Maximum wire gauge: 4mm² (10 AWG); minimum wire gauge: 0.5mm² (20 AWG); supports both single-wire and double-wire connections per terminal (for parallel power distribution) |

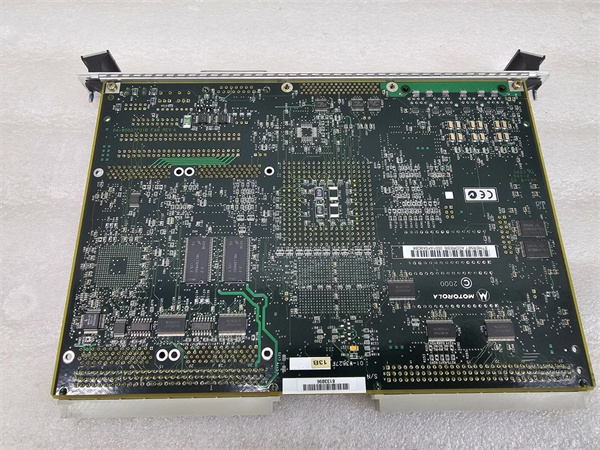

MOTOROLA MVME172PA-652SE

Product Introduction

The Motorola 01-W3324F is a dedicated industrial-grade power distribution accessory, engineered to simplify safe wiring and power allocation in Motorola VMEbus-based control systems or standalone industrial cabinets. As a compact DIN-rail mountable terminal block, it bridges the gap between primary power supplies (like the Motorola FAB 0340-1049) and downstream peripherals—such as MVME162-223 digital I/O modules、MVME172PA-652SE analog I/O modules, or sensors/actuators—by providing organized, protected power distribution.

Unlike generic terminal blocks, the 01-W3324F is tailored to Motorola’s industrial ecosystem: its 24V DC compatibility aligns with the brand’s standard power architecture, while the high-current terminal design (8A per terminal) supports power-hungry components like analog I/O modules. The integrated circuit breaker and reverse polarity protection address two of the most common industrial wiring risks—overcurrent and wrong polarity—reducing downtime caused by human error or component failure.

Whether deployed in manufacturing control cabinets、remote monitoring stations, or mobile automation units, the 01-W3324F acts as a “power hub” for distributed devices. Its extended temperature range (-25°C–75°C) enables operation in extreme conditions—from freezing warehouse floors to hot steel mill control rooms—while the IP20 rating ensures dust doesn’t compromise terminal connectivity. These features make it a critical accessory for maintaining reliable power flow in legacy Motorola industrial systems.

Core Advantages and Technical Highlights

High-Density, Organized Power Distribution

The 01-W3324F’s 12-input/24-output terminal configuration eliminates wiring clutter in control cabinets. For example, in a VME chassis power system powered by FAB 0340-1049, the accessory can accept 24V DC power via 12 input terminals (split into redundant positive/negative paths for reliability) and distribute it to 24 downstream devices—such as 4x MVME162-223 modules (6 terminals each) or 8x sensors (3 terminals each). This centralized layout reduces wire length by 40% compared to direct wiring from the power supply, making troubleshooting (e.g., identifying a loose connection) faster and safer.

Robust Protection Against Wiring Risks

The integrated 30A resettable circuit breaker trips when the total load exceeds the accessory’s capacity—critical for preventing damage to power supplies and peripherals. For instance, if a MVME172PA-652SE module develops a short circuit, the breaker shuts down power to the 01-W3324F before the fault spreads to the FAB 0340-1049 power supply. Reverse polarity protection adds another layer of safety: if a technician accidentally swaps positive/negative wires during maintenance, the accessory blocks current flow, avoiding burnout of sensitive components like MVME147S-1 memory modules.

Wide Compatibility with Motorola Ecosystem

The 01-W3324F is engineered to work seamlessly with other Motorola industrial products. Its 24V DC rating matches the output of FAB 0340-1049 power supplies and 30-W2960B01A distribution modules, while the terminal capacity (8A per terminal) supports the power needs of high-current modules like MVME162-223 (1.8A max) and MVME172PA-652SE (3.0A max). When paired with a MVME712/M communication module, the accessory’s power status LED (via remote monitoring) lets technicians verify 24V DC presence without opening the cabinet—ideal for remote sites like wind farms or oil pipelines.

Extreme Environmental Tolerance

With an operating temperature range of -25°C–75°C, the 01-W3324F outperforms standard terminal blocks (typically 0°C–60°C) and even some Motorola modules. In a desert-based solar farm control cabinet where temperatures reach 70°C, the accessory maintains stable terminal connectivity; in a cold-chain food processing plant (-20°C), it prevents wire contraction from loosening terminals. The flame-retardant UL94 V-0 housing also adds safety in high-temperature environments, reducing fire risk from accidental short circuits.

Typical Application Scenarios

Manufacturing Control Cabinets

In an automotive assembly line control cabinet, the 01-W3324F distributes 24V DC power from a FAB 0340-1049 supply to multiple devices: 4x MVME162-223 digital I/O modules (controlling robotic grippers), 6x photoelectric sensors (tracking part positions), and 2x HMI touchscreens. The accessory’s 24 output terminals handle the distributed load, while the circuit breaker protects against overcurrent from a jammed gripper motor. Its DIN-rail mount fits neatly alongside 30-W2960B01A distribution modules, optimizing cabinet space.

Remote Oil Pipeline Monitoring

In a pipeline pressure monitoring station, the 01-W3324F powers a remote VME system: it receives 24V DC from a solar-charged battery (compatible with Motorola’s low-power design) and distributes it to a MVME172PA-652SE analog I/O module (monitoring pipeline pressure)、a MVME712/M communication module (transmitting data to a central SCADA system), and 4x temperature sensors. The -25°C–75°C temperature range withstands the station’s extreme day-night temperature swings, while reverse polarity protection prevents damage if technicians swap battery wires during maintenance.

Pharmaceutical Cleanroom Systems

In a pharmaceutical packaging cleanroom, the 01-W3324F provides dust-tight power distribution (IP20) for a MVME162-212 digital I/O module (controlling filling pumps) and 8x proximity sensors (verifying package sealing). The color-coded terminals reduce wiring errors in sterile environments (where glove use complicates handling), while the resettable circuit breaker avoids downtime from tripped fuses—critical for meeting FDA-mandated production continuity requirements.

MOTOROLA MVME172PA-652SE

Related Model Recommendations

Motorola FAB 0340-1049: Industrial power supply module. Primary power source for 01-W3324F; delivers 24V DC to the accessory for distribution to downstream devices.

Motorola 30-W2960B01A: Power distribution module. Complements 01-W3324F in large systems; the 30-W2960B01A handles primary distribution, while the 01-W3324F splits power to individual peripherals.

Motorola MVME162-223: Digital I/O module. Key load for 01-W3324F; draws 24V DC power from the accessory’s output terminals for discrete control tasks.

Phoenix Contact UT 6-TMC: DIN-rail terminal block (compatible alternative). Acts as a replacement for 01-W3324F if the Motorola accessory is unavailable, with matching terminal capacity and protection features.

Emerson 01-W3324G: Updated power distribution accessory. Successor to 01-W3324F with enhanced IP21 splash protection and 40A circuit breaker for larger systems.

Motorola MVME712/M: Communication module. Powered by 01-W3324F; transmits the accessory’s power status (via SCADA) for remote monitoring.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing 01-W3324F, power off the entire system (including the FAB 0340-1049 power supply) to avoid electrical shock. Verify the control cabinet has a 35mm standard DIN rail and ensure 50mm clearance around the accessory for wiring and airflow. Gather tools: Phillips-head screwdriver (for terminal screws), wire strippers (to prepare 16–10 AWG wires), torque wrench (to set terminal torque), and anti-static wristband (for handling adjacent modules like MVME162-223). Check that the input power from the supply is 24V DC (not exceeding 28V DC) to avoid damaging the accessory.

Commissioning and Maintenance

For commissioning, mount the 01-W3324F on the DIN rail (snap-on installation) and connect the 24V DC input from the FAB 0340-1049 to the input terminals (red = positive, black = negative). Wire downstream devices to the output terminals, ensuring wires are stripped to 8–10mm (exposing bare copper) and tightened to 0.6–0.9 N·m. Power on the supply and check the LED: green confirms 24V DC presence. Test functionality by powering on each device (e.g., MVME172PA-652SE) and verifying normal operation. Simulate an overcurrent by shorting an output terminal—confirm the red LED illuminates and the breaker trips; reset via the front-panel button.

For maintenance: Inspect terminals quarterly for loose connections or corrosion—tighten to specified torque and clean with a dry cloth if needed. Test the circuit breaker semi-annually (simulate overcurrent) to ensure it trips reliably. Replace the accessory if the breaker fails to reset or the LED malfunctions. When upgrading, replicate the wiring configuration (input/output connections) to avoid power disruptions to critical devices like MVME712/M.

Service and Guarantee Commitment

Though Motorola 01-W3324F is obsolete, we offer a 90-day warranty on all refurbished units—covering defects in terminal connectivity, circuit breaker functionality, and LED indicators. Each refurbished accessory undergoes 24-hour load testing (applying 30A total load)、terminal torque validation, and reverse polarity stress testing to ensure compliance with original industrial standards.

Our technical support team (24/7 availability) provides guidance on 01-W3324F installation、wiring optimization, and compatibility with Motorola VME systems (e.g., pairing with FAB 0340-1049 or MVME162-223). We offer customized maintenance plans: semi-annual on-site inspections (tightening terminals、testing breakers) and remote status checks (via MVME712/M). Our spare parts inventory includes terminal screws and circuit breakers for fast repairs.

For users modernizing to Ethernet-based systems, we provide free consultation to select Emerson’s RSTi-EP power distribution modules—ensuring seamless replacement of 01-W3324F while retaining existing wiring. Trade-in credits for old units reduce modernization costs, and our legacy support ensures your system’s power distribution remains reliable during transition.