Description

Key Technical Specifications

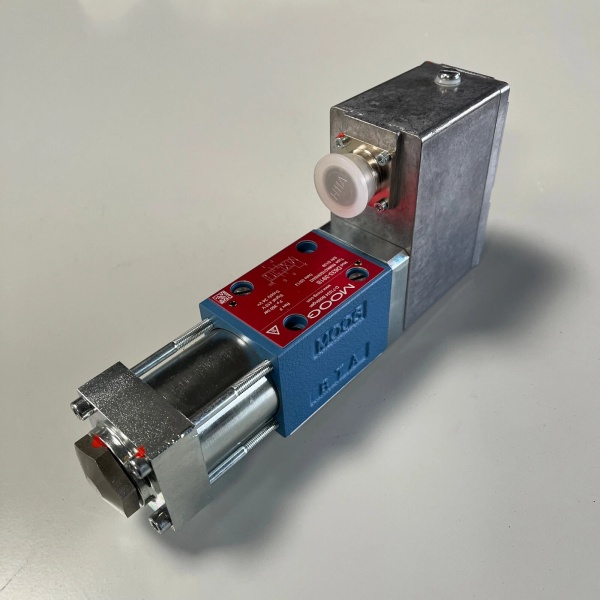

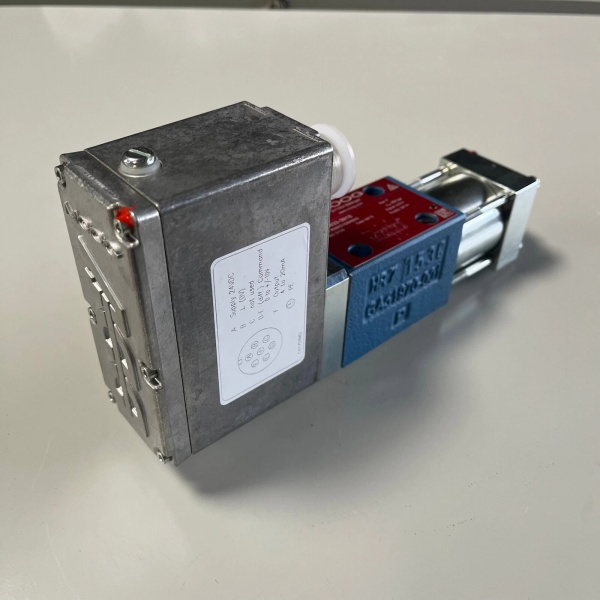

- Model Number: D662-4602K

- Manufacturer: Moog Inc. (Industrial Motion Control Group)

- Valve Type: Two-stage servo valve with integrated PQ control electronics

- Actuation Principle: ServoJet jet pipe pilot (permanent magnet torque motor) + sliding spool power stage

- Size Classification: ISO 4401 Size 05 (NG10) – 4-bolt flange (M8 x 1.25)

- Flow Capacity: 120 L/min (31.7 gpm) at Δp=70 bar

- Maximum Operating Pressure: 350 bar (5075 psi) – continuous service; 380 bar proof pressure

- Electrical Interface: ±10V/4-20mA switch-selectable input (12-bit resolution), 24V DC ±10% supply, ±10V LVDT spool position feedback

- Connector Type: 10-pin DIN 43650 A (IP65 when mated with sealed boot)

- Response Time: 10ms (90% step response); 7ms (high-response “H” variant)

- Operating Temperature: -20°C to +70°C (-4°F to +158°F)

- Fluid Requirements: Mineral oil (ISO VG 32–68), NAS 1638 Class 5, max 85°C fluid temp

- Mounting Torque: 25 Nm (18.4 ft-lbs)

- Weight: 5.1kg (11.2 lbs)

- Certifications: CE, RoHS compliant; ATEX/IECEx optional (Zone 2 hazardous areas)

Moog D633-481B

Field Application & Problem Solved

In industrial hydraulic systems that demand both high precision and rugged reliability—think injection molding main clamp control, steel mill roll gap regulation, or test rig dynamic load profiling—the biggest pain point is external electronics failure. Generic servo valves require separate PQ controllers, which add wiring, create ground loop issues, and fail prematurely in harsh environments. A Michigan injection molder lost $190k/year to scrap because their external controller couldn’t sync pressure and flow during clamp activation, leading to part misalignment. A Pennsylvania steel mill dealt with 5-hour downtime events every quarter when external modules shorted due to moisture ingress.

This valve eliminates that risk by integrating all PQ control electronics directly into the valve body. You’ll find it in: injection molding main clamps (maintaining ±1% pressure accuracy to prevent mold damage), steel mill hot rolling stands (controlling roll gap to ±0.05mm for uniform sheet thickness), paper machine calenders (nip pressure control for consistent web quality), and heavy-duty test rigs (replicating real-world load profiles up to 80Hz). Its core value is integrated robustness + precision—the ServoJet pilot resists contamination 40% better than nozzle-flapper designs, and no external electronics mean 50% fewer failure points. For the Michigan molder, it dropped scrap rates from 7% to 0.9%. For the steel mill, it cut electronics-related downtime by 90%.

Installation & Maintenance Pitfalls (Expert Tips)

- Fluid Cleanliness: NAS 1638 Class 5 Is Non-Negotiable: The ServoJet pilot’s 0.45mm jet pipe orifice clogs with NAS 6 oil. I replaced three valves at an Ohio paper mill where the client used 10µm filters—each failure cost 4 hours of production. Fix: Install 5µm absolute filters (β10 ≥ 100 per ISO 16889) and test oil cleanliness every 2000 hours. De-aerate oil to prevent cavitation in the pilot stage.

- Single-Point Grounding Kills Signal Noise: Rookies ground the valve and controller at different points, creating ground loops that corrupt LVDT feedback. A Wisconsin molder had clamp pressure drift until we re-grounded everything to the same machine frame point. Fix: Use shielded twisted-pair for control signals, ground only at the controller, and keep signal cables 30cm away from power lines or VFDs.

- Pilot Pressure: Lock It to 8–12 Bar: Too low (≤6 bar) causes slow response; too high (≥15 bar) burns out the torque motor. A Tennessee test rig’s load profiles were erratic until we adjusted the pilot regulator to 10 bar. Fix: Install a dedicated gauge on the pilot supply and check weekly—fluctuations indicate a clogged filter or faulty regulator.

- Null Adjustment: No Load, No Pressure: Adjusting null with system pressure on the ports causes drift when loads change. I spent 3 hours troubleshooting a Kentucky mill’s roll gap drift until I realized the tech calibrated with 220 bar on the actuator. Fix: Depressurize the system, apply 0V/4mA, and adjust the null screw until feedback reads 0V (±0.01V). Lock with the jam nut and recheck after 30 minutes of run time.

- Mounting Torque: 25 Nm Exact—Not 30: Over-torquing warps the valve body, binding the spool and increasing hysteresis. An Indiana test rig’s valve had 0.2% flow error until we retorqued bolts to 25 Nm with a torque wrench. Use the cross-tightening sequence (1-3-2-4) to distribute force evenly.

Moog D633-481B

Technical Deep Dive & Overview

The D662-4602K is a workhorse designed for the harshest industrial environments, combining two-stage performance with integrated electronics to eliminate external control modules. At its core, it uses Moog’s patented ServoJet jet pipe pilot stage— a rotating jet pipe that directs fluid to two receiver nozzles, creating differential pressure to shift the power spool. This design is self-cleaning (small particles are flushed through the jet pipe), reducing clogging failures by 40% compared to traditional nozzle-flapper pilots.

The power stage features a hard-chromed spool with 0.004mm clearances, minimizing leakage and ensuring precise flow control. A built-in LVDT tracks spool position in real time, feeding data to the integrated microprocessor. The onboard electronics execute PQ coordination algorithms—users can prioritize flow, pressure, or balance both—delivering sub-2% control accuracy without external hardware.

The permanent magnet torque motor provides precise, repeatable actuation of the jet pipe, translating electrical commands into smooth spool movement. The spring-centered spool offers a critical fail-safe: power loss sends the spool to neutral, blocking flow to actuators and preventing equipment damage.

What sets this valve apart is its integration—no external controllers mean fewer wires, less moisture ingress risk, and faster troubleshooting. The ISO 4401 Size 05 flange fits standard manifolds, making retrofits straightforward. For field service teams, it’s a low-maintenance solution: the ServoJet pilot resists contamination, the integrated electronics include self-diagnostics, and the modular design allows for quick coil or filter replacement. It’s not just a valve—it’s a compact, rugged PQ control system that delivers the precision industrial processes demand without the fragility of external electronics.