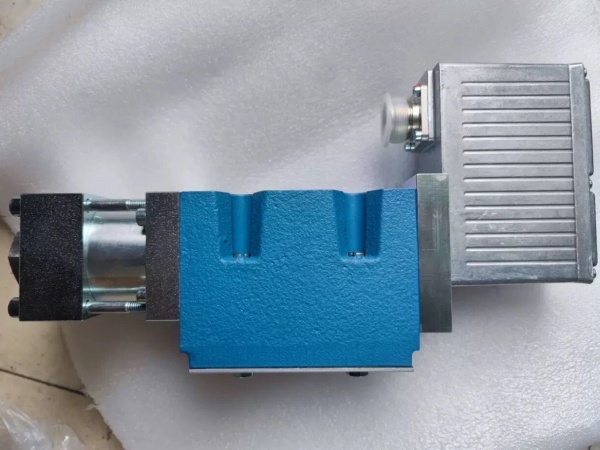

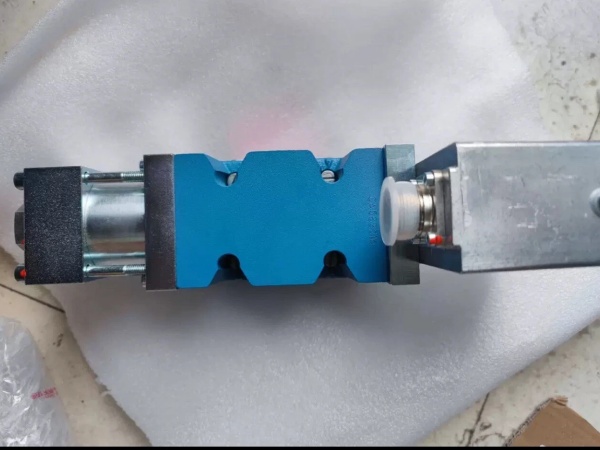

Description

Key Technical Specifications

- Model Number: D634-319C

- Manufacturer: Moog Inc. (Industrial Motion Control Group)

- Valve Type: 4-way direct drive servo valve (DDV) with integrated electronics

- Actuation Principle: Rare-earth permanent magnet linear force motor (direct spool drive, no pilot stage)

- Size Classification: ISO 4401 Size 05 (NG10)

- Flow Capacity: 160 L/min (42.3 gpm) at Δp=70 bar

- Maximum Operating Pressure: 420 bar (6090 psi)

- Electrical Interface:

- Supply Voltage: 24V DC ±10% (21.6-26.4V)

- Control Input: ±10V analog (12-bit resolution)

- Feedback Output: ±10V spool position (12-bit resolution)

- Connector: 6-pin DIN 43650 A (IP65 protection)

- Coil Current: 350mA nominal, 700mA peak

- Response Time: 2.5ms (90% step response)

- Operating Temperature: -25°C to +70°C (-13°F to +158°F)

- Fluid Requirements: Mineral oil (ISO VG 32-68), NAS 1638 Class 6, max 85°C fluid temp

- Mounting Torque: 28 Nm (flange bolts)

- Weight: 6.1kg (13.4 lbs)

- Certifications: CE, RoHS compliant, ATEX/IECEx certified for hazardous areas (optional)

- Compatible Systems: MOOG D136 MSC I Controllers, D138 MACS Licenses, M3000 Motion Control Systems, large hydraulic actuators (50-150mm bore)

MOOG D634-319C

Field Application & Problem Solved

In mid-to-large hydraulic systems—think 100-ton hydraulic presses, steel mill hot rolling stands, or injection molding main clamps—the biggest pain point is balancing high flow demands with precision control. Pilot-operated valves can’t keep up: they have laggy response (5-7ms) and require bulky pilot systems that add leak points and maintenance. Generic high-flow valves lack the closed-loop precision needed for tasks like rolling mill gap control (±0.02mm tolerance) or press ram positioning (±0.1mm accuracy). A steel mill in Pennsylvania was losing $270k annually to sheet thickness defects because their pilot valves couldn’t respond fast enough to load changes. A press shop in Ohio spent $32k/year on pilot filter replacements and experienced 8 unplanned shutdowns when pilot lines clogged.

This valve solves that by delivering high flow (160 L/min) without sacrificing precision. You’ll find it in: steel mill hot/cold rolling stand actuators (controlling roll gap for consistent sheet metal thickness), large hydraulic presses (ram speed and position control for stamping or forming), injection molding machine main clamps (maintaining clamp force during injection), and heavy-duty test rigs (dynamic load profiles for automotive or aerospace components). Its core value is high-flow performance + direct drive simplicity—no pilot supply means 80% fewer maintenance points, the 2.5ms response time outperforms pilot valves by 50%, and the integrated amplifier cuts wiring complexity. For the Pennsylvania steel mill, swapping to this valve reduced thickness defects by 75% and eliminated pilot system-related downtime.

Installation & Maintenance Pitfalls (Expert Tips)

- Fluid Cleanliness: NAS 1638 Class 6 Is Non-Negotiable: Rookies use NAS 8 oil thinking “it’s close enough,” but this valve’s spool clearances (0.004mm) will bind within 3-6 months. I replaced three valves at an Ohio press shop where the client skipped proper filtration—each failure cost 4 hours of downtime. Fix: Install dual-stage 10µm filters (β10 ≥ 75 per ISO 16889) and test oil cleanliness every 1500 operating hours.

- Wiring: Don’t Reverse Polarity on the Amplifier: Swapping 24V+ and GND burns out the integrated amplifier—an expensive mistake ($800+ repair). A Texas test rig’s valve failed in 15 seconds because the tech mixed up wires. Fix: Use Moog’s color code (red = 24V+, black = GND, white = control in, blue = feedback out) and verify with a multimeter before powering up.

- Mounting Torque: 28 Nm Exact—Not 25 or 30: Over-torquing warps the valve body, causing spool binding and erratic flow; under-torquing leads to leaks. A Michigan steel mill’s rolling stand valve had 0.05mm position error until we retorqued the bolts to 28 Nm with a torque wrench. Use the cross-tightening sequence (1-3-2-4) to distribute force evenly.

- Null Adjustment: Depressurize and Calibrate to Feedback: Adjusting null under pressure creates drift. After mounting, bleed the system, apply 0V to the valve, and turn the null screw until the feedback output reads 0V (±0.01V). A Wisconsin injection molding plant’s clamp force was inconsistent until we performed this calibration—don’t rely on “factory null” after shipping.

- Connector Protection: Seal Against Fluid Mist: The IP65 connector works for splash, but hydraulic fluid mist (common in press enclosures) seeps in over time, corroding pins. I’ve replaced half a dozen amplifiers at a Louisiana refinery where connectors were unprotected. Fix: Use a Moog connector boot (P/N 014-003-002) and tighten the coupling nut to 0.6Nm—inspect quarterly for corrosion.

MOOG D634-319C

Technical Deep Dive & Overview

The MOOG D634-319C is a high-flow direct drive servo valve built for the most demanding industrial hydraulic systems—where 160 L/min flow and ±0.01mm precision must coexist. At its core, a rare-earth permanent magnet linear force motor drives the spool directly, eliminating the pilot stage that plagues traditional valves. This design cuts response time to 2.5ms because there’s no lag from pilot pressure buildup—critical for applications like rolling mills, where load changes happen in milliseconds.

The integrated 24V amplifier creates a self-contained control loop: it accepts a ±10V command from a motion controller (e.g., MOOG D136), uses an internal LVDT to monitor spool position, and adjusts the force motor current to maintain position within ±0.01mm—even as fluid temperature or pressure fluctuates. The spring-centered spool provides a fail-safe: power loss triggers springs to push the spool to neutral, blocking flow to both actuator ports and preventing unintended movement—a safety must for heavy machinery.

What sets it apart from generic high-flow valves is its closed-loop precision and ruggedness. The hard-chromed spool (0.5µm surface finish) resists wear, and the ISO 4401 Size 05 flange fits standard hydraulic manifolds, simplifying retrofits. The 420 bar pressure rating handles the peak loads of large presses and rolling stands, while the IP65 rating protects against dust and water in harsh plant environments. Unlike pilot valves, it requires no dedicated pilot supply, filters, or regulators—reducing system complexity and failure points. For maintenance teams, it’s a workhorse: 20,000+ hours of service life with proper fluid care, and the integrated diagnostics (via the feedback signal) make troubleshooting fast—no need for specialized tools to check spool position. It’s not just a valve—it’s the backbone of high-performance, low-maintenance hydraulic control in heavy industry.