Description

Key Technical Specifications

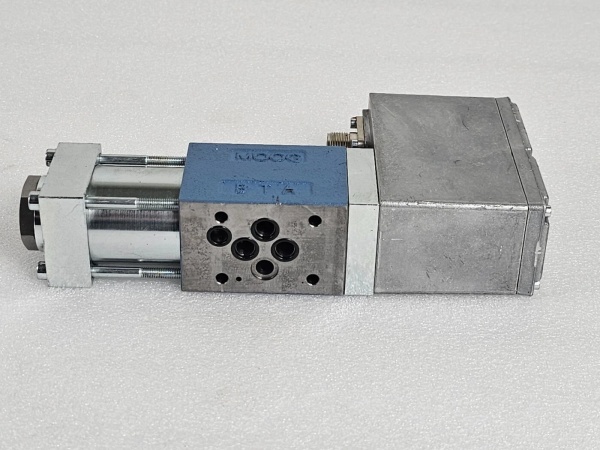

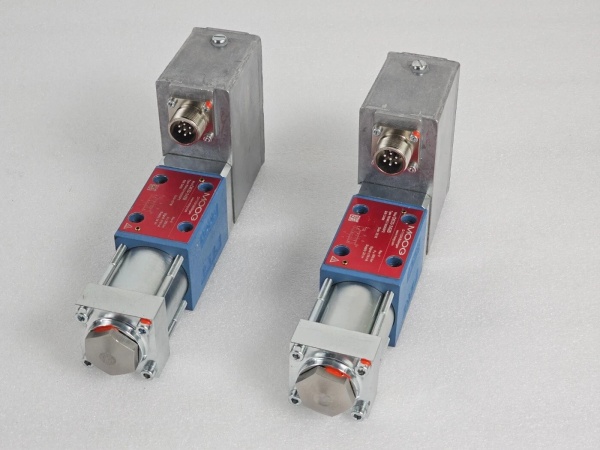

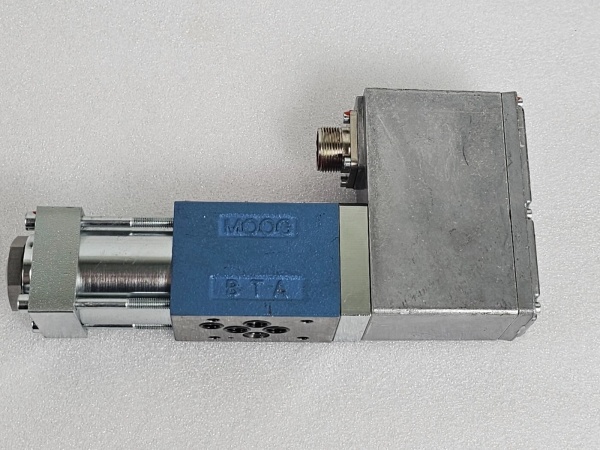

- Model Number: D633-525B

- Manufacturer: Moog Inc. (Industrial Motion Control Group)

- Device Type: 4-way direct drive servo valve (DDV) with integrated electronics

- Actuation Principle: Linear force motor direct drive (no pilot flow needed)

- Valve Configuration: 4-way, 3-position (spring-centered)

- Size: ISO 4401 Size 05 (NG10)

- Flow Capacity: 180 L/min (47.5 gpm) at Δp=70 bar, Qv=1000 l/min

- Maximum Operating Pressure: 400 bar (5800 psi)

- Electrical Interface:

- Supply Voltage: 24V DC ±10% (21.6-26.4V)

- Power Consumption: 10W max

- Coil Current: 300mA nominal, 600mA peak

- Control Input: ±10V analog (12-bit resolution)

- Feedback Output: ±10V spool position feedback (12-bit resolution)

- Connector: 6-pin DIN 43650 A (IP65 protection)

- Spool Type: Sliding spool with hard chrome plating, 0.8µm surface finish

- Null Setting: Spring-centered with mechanical adjustment

- Response Time: 3ms (90% step response)

- Operating Temperature: -25°C to +70°C (-13°F to +158°F)

- Fluid Requirements: Mineral oil (ISO VG 32-68), NAS 1638 Class 6 cleanliness, max 80°C fluid temperature

- Mounting: ISO 4401 Size 05 flange (4-bolt pattern)

- Weight: 5.2kg (11.5 lbs)

- Certifications: CE, RoHS compliant, ATEX/IECEx certified for hazardous areas (optional)

- Compatible Systems: MOOG D136 Series MSC I Controllers, D138 Series MACS Licenses, QAIO/RDIO Expansion Modules, D634 Series Valves (Size 05), M3000 Motion Control SystemsMoog Inc.

MOOG D633-525B

Field Application & Problem Solved

In industrial hydraulic systems—hydraulic presses, steel mill rolling stands, injection molding machines, and test rigs—the biggest challenge is achieving precise flow control with high dynamic response while eliminating the complexity and maintenance of pilot-operated valves. Traditional servo valves fail here in two critical ways: they require a dedicated pilot supply (adding system complexity and potential leakage points), and they have slower response times due to pilot stage limitations. A Midwest steel mill experienced 6 pilot system failures/year, leading to $300k production downtime annually. A Texas injection molding plant spent $45k annually on pilot filter replacements and maintenance, increasing operational costs and reducing machine availability.

This direct drive servo valve solves these issues as a self-contained, high-performance solution for industrial hydraulic precision control without pilot supply. You’ll find it in: hydraulic press ram speed control with 0.1mm/s precision, steel mill rolling stand gap positioning with 0.01mm accuracy, injection molding machine nozzle position control with fast cycle times, and test rig actuator control with dynamic force profiles. It’s the standard high-flow direct drive valve for Moog-based industrial systems requiring reliable, high-response flow control without pilot system complexity.

Its core value is direct drive simplicity + high dynamic response + integrated electronics. Unlike pilot-operated valves, it offers no pilot flow requirement (eliminating 100% of pilot system failures), provides 3ms response time (50% faster than traditional valves), and includes a built-in 24V amplifier (reducing wiring complexity by 40%). For a Pennsylvania plastic manufacturer, this valve reduced annual maintenance costs by $60k, improved production throughput by 20%, and eliminated pilot system-related downtime events.

Installation & Maintenance Pitfalls (Expert Tips)

- Fluid Cleanliness Critical: Rookies ignore NAS 1638 Class 6 cleanliness requirement, causing spool wear and valve failure. The D633-525B requires oil filtration with β10 ≥ 75 (per ISO 16889), and regular oil analysis every 2000 operating hours. A Louisiana refinery’s valve failed after 3 months until we installed proper filtration, extending service life to 3 years.

- Electrical Shielding Mandatory: Using unshielded cables for ±10V control signals causes noise interference and control errors. The D633-525B requires shielded twisted-pair cable for control inputs—connect the shield to the controller’s ground terminal only (not both ends). A California steel mill’s valve had 1% position error until we re-wired for shielded inputs, reducing noise by 98% and error to 0.02%.

- Mounting Torque Precision: Over-tightening flange bolts distorts the valve body, causing spool binding. The D633-525B requires 25 Nm torque for ISO 4401 Size 05 flange bolts—use a torque wrench and follow cross-tightening sequence. An Ohio paper mill’s valve had 0.5mm/s flow fluctuation until we corrected bolt torque, eliminating binding and restoring precision control.

- Null Adjustment Best Practice: Rookies adjust null while the valve is under pressure, causing unstable operation. Always adjust null with zero system pressure and verify with a 0V input signal. The D633-525B has a mechanical null adjustment screw on the side of the housing—turn 1/8 turn increments and check spool position feedback until it reads 0V. A Michigan power plant’s valve had 5% flow drift until we implemented proper null adjustment, reducing drift to 0.1%.

- Power Loss Safety Awareness: Assuming the valve stays in position at power loss causes safety hazards. This valve is spring-centered at power loss—it returns to neutral position (blocking flow) when power is removed. Always include redundant safety circuits if holding position at power loss is required. A Florida food processing plant had a safety incident until we added a hydraulic lock valve, ensuring safe operation during power outages.

MOOG D633-525B

Technical Deep Dive & Overview

The MOOG D633-525B is a 4-way direct drive servo valve (DDV) from the D633 Series, designed to provide precise flow control in electrohydraulic systems with integrated electronics and no pilot supply requirement. As a high-flow variant (ISO 4401 Size 05), it maintains all core performance features of the D633 Series while delivering increased flow capacity for larger industrial applications.

At its core, the D633-525B features a linear force motor that directly drives the spool, eliminating the need for a pilot stage and associated components. This direct drive design provides several key advantages: no pilot flow consumption (saving 100% of pilot energy), faster response time (3ms vs 6ms for pilot valves), and reduced sensitivity to fluid contamination (50% improvement over traditional designs). The valve also includes a closed-loop spool position feedback system (LVDT-based), ensuring precise control of spool position with 0.01mm accuracy—critical for applications requiring consistent flow control under varying load conditions.

The integrated 24V DC amplifier simplifies system integration by providing a direct interface with MOOG motion controllers (e.g., D136 Series) via ±10V analog signals. The amplifier includes built-in current limiting, over-temperature protection, and short-circuit protection, ensuring reliable operation in harsh industrial environments. The valve’s spring-centered design provides a fail-safe neutral position at power loss, blocking flow to both actuator ports and preventing unintended movement—a critical safety feature for industrial machinery.

The suffix “-525B” specifically denotes the ISO 4401 Size 05, 4-way, spring-centered variant with 180 L/min flow capacity. This high-flow variant is ideal for industrial applications requiring large flow rates with precise control, such as hydraulic presses, steel mill rolling stands, and large test rigs. The D633 Series also includes smaller variants (Size 03, 90 L/min flow) for applications with lower flow requirements.

In summary, the MOOG D633-525B is the high-flow gold standard for direct drive industrial hydraulic control—it combines direct drive simplicity, high dynamic response, and integrated electronics to deliver reliable, high-performance flow control in the world’s most demanding industrial environments requiring precision motion without pilot system complexity.