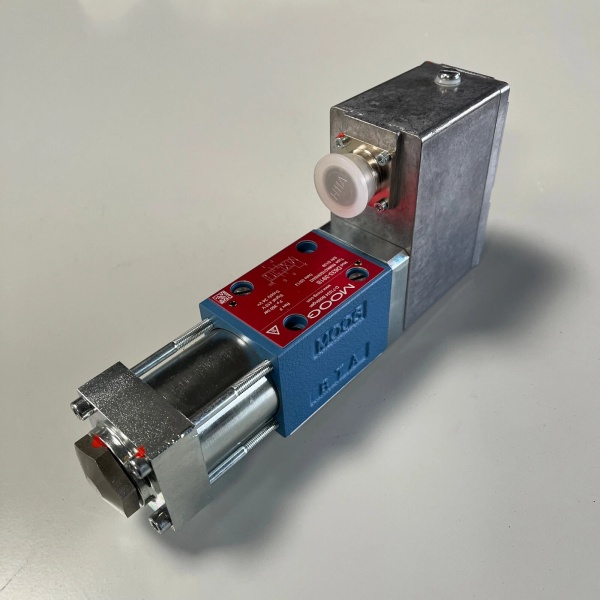

Description

Key Technical Specifications

- Model Number: D633-481B

- Manufacturer: Moog Inc. (Industrial Motion Control Group)

- Valve Type: 4-way direct drive servo valve (DDV) with integrated electronics

- Actuation Principle: Permanent magnet linear force motor (direct spool drive, no pilot)

- Size Classification: ISO 4401 Size 03 (NG6)

- Flow Capacity: 90 L/min (23.8 gpm) at Δp=70 bar

- Maximum Operating Pressure: 400 bar (5800 psi)

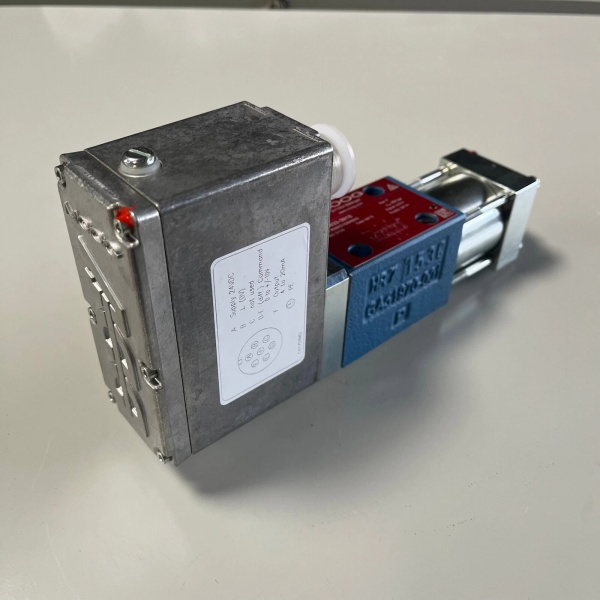

- Electrical Interface:

- Supply Voltage: 24V DC ±10% (21.6-26.4V)

- Control Input: ±10V analog (12-bit resolution)

- Feedback Output: ±10V spool position (12-bit resolution)

- Connector: 6-pin DIN 43650 A (IP65 protection)

- Coil Current: 250mA nominal, 500mA peak

- Response Time: 2ms (90% step response)

- Operating Temperature: -25°C to +70°C (-13°F to +158°F)

- Fluid Requirements: Mineral oil (ISO VG 32-68), NAS 1638 Class 6, max 80°C fluid temp

- Mounting Torque: 15 Nm (flange bolts)

- Weight: 2.8kg (6.2 lbs)

- Certifications: CE, RoHS compliant, ATEX/IECEx optional

- Compatible Systems: MOOG D136 MSC I Controllers, D138 MACS Licenses, M3000 Motion Control Systems, small hydraulic actuators (<50mm bore)

Moog D633-481B

Field Application & Problem Solved

In the field, small-to-mid hydraulic systems—think injection molding ejectors, paper machine edge guides, or bench-top test rigs—face a unique frustration: pilot-operated servo valves are overkill in size and complexity, while generic proportional valves lack the precision needed for dynamic control. The biggest headache? Pilot valves require dedicated supply lines, filters, and regulators—adding leak points, maintenance, and cost to systems that don’t have the space or budget for extra hardware. A paper mill in Wisconsin was replacing pilot filters on their edge guide actuators every 3 months, costing $18k annually and causing 2-hour downtime events when filters clogged. A plastics plant in Ohio struggled with generic valves that couldn’t keep up with 0.1s ejector cycle times, leading to part defects.

This valve solves that by packing direct drive performance into a compact Size 03 package. You’ll find it in: injection molding machine ejector and core puller control (where fast response and small footprint matter), paper machine edge guide and tension control actuators (tight spaces near rolls), small hydraulic presses (up to 50-ton capacity), and test rigs (dynamic force profiles for component testing). Its core value is simplicity without sacrifice—no pilot supply means fewer parts to fail, integrated electronics cut wiring time by 30%, and the 2ms response time outperforms generic valves by 50%. For the Wisconsin paper mill, swapping to this valve eliminated pilot filter maintenance entirely, saving $18k/year and cutting downtime by 16 hours annually.

Installation & Maintenance Pitfalls (Expert Tips)

- Fluid Cleanliness Is Non-Negotiable (NAS 1638 Class 6): Rookies think “close enough” filtration works, but this valve’s tight spool clearances (0.005mm) will bind with NAS 8 oil. I’ve seen a Michigan test rig’s valve fail in 6 weeks because they used a 25µm filter instead of 10µm. Fix: Install β10 ≥ 75 filters (ISO 16889) and test oil cleanliness quarterly—don’t skip this.

- Shielded Wiring for Control Signals: Unshielded cables pick up noise from VFDs or motor cables, causing 0.5-1% position error. A plastics plant in Ohio had ejector misalignment until we rerouted the ±10V signal with shielded twisted-pair, grounded only at the controller. Never ground both ends—this creates ground loops that corrupt feedback.

- Mounting Torque: 15 Nm Exact (Not 25!): Size 03 flanges are thinner than Size 05—over-torquing to 25 Nm warps the valve body, binding the spool. A Indiana press shop’s valve had erratic flow until we retorqued bolts to 15 Nm with a torque wrench. Use the cross-tightening sequence (1-3-2-4) to distribute force evenly.

- Null Adjustment: Depressurize First: Adjusting null while the system is under pressure leads to drift and unstable operation. I’ve wasted 2 hours troubleshooting a Tennessee test rig’s valve only to find the tech adjusted null with 100 bar on the ports. Fix: Bleed pressure, apply 0V input, and tweak the null screw until feedback reads ±0.01V—lock with the jam nut.

- Don’t Over-Size the Valve: Just because it fits doesn’t mean it’s right. A client in Illinois used this valve on a 100-ton press (needing 120 L/min) and wondered why response was slow. This valve maxes out at 90 L/min—use Size 05 (D633-525B) for higher flow. Over-sizing causes cavitation and poor control.

Moog D633-481B

Technical Deep Dive & Overview

The D633-481B is a compact direct drive servo valve designed for small-to-mid hydraulic systems where space, simplicity, and precision collide. At its core, a permanent magnet linear force motor drives the spool directly—no pilot stage, no pilot flow, no extra hardware. This design cuts response time to 2ms (faster than pilot valves) because there’s no lag from pilot pressure buildup. The integrated 24V amplifier simplifies integration: it takes a ±10V command signal from a controller (like MOOG’s D136), uses an internal LVDT to monitor spool position, and adjusts the force motor current to maintain position within ±0.01mm—even with fluid temperature swings or pressure changes.

The spring-centered spool provides a fail-safe: if power cuts out, springs push the spool to neutral, blocking flow to both actuator ports and preventing unintended movement—critical for safety in press or injection molding applications. The Size 03 (NG6) flange makes it ideal for tight spaces, like between paper machine rolls or inside injection molding machine frames, where larger valves won’t fit. The hard-chromed spool (0.8µm surface finish) resists wear from clean oil, extending service life to 20,000+ hours with proper maintenance.

Unlike generic proportional valves, this is a closed-loop system—feedback ensures consistency, even as the valve ages. The IP65-rated connector stands up to dust and occasional moisture in plant environments, and the Viton seals handle standard mineral oils (ISO VG 32-68) without degradation. It’s not just a valve—it’s a self-contained control solution that eliminates the complexity of pilot systems, reduces maintenance, and delivers the precision industrial systems demand.