Description

Key Technical Specifications

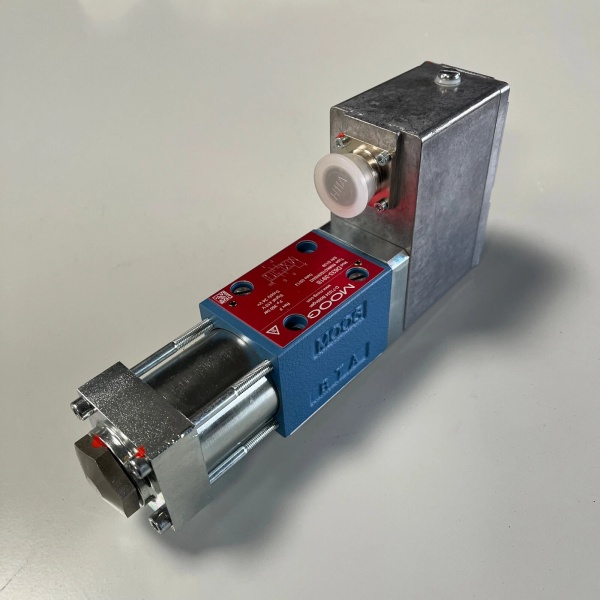

- Model Number: D633-317B

- Manufacturer: Moog Inc. (Industrial Motion Control Group)

- Valve Type: 4-way direct drive servo valve (DDV) with integrated electronics

- Actuation Principle: Permanent magnet linear force motor (direct spool drive—no pilot stage)

- Size Classification: ISO 4401 Size 03 (NG6) – 4-bolt flange pattern (M6 x 1.0)

- Flow Capacity: 30 L/min (7.9 gpm) rated (Δp=35 bar), 75 L/min (19.8 gpm) max (Δp=70 bar)

- Maximum Operating Pressure: 350 bar (5000 psi) – continuous service

- Electrical Interface:

- Supply Voltage: 24V DC (19–32V DC wide range)

- Control Input: ±10V/±10mA/4-20mA analog (12-bit resolution)

- Feedback Output: ±10V spool position (12-bit resolution)

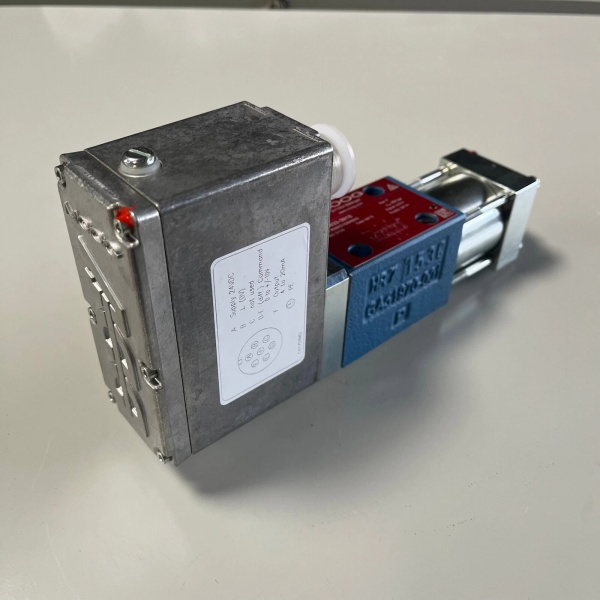

- Connector: 7-pin configuration (IP65 when mated)

- Drive Technology: Pulse Width Modulation (PWM) current control

- Response Time: ≤12ms (90% step response from 0–100% command)

- Operating Temperature: -25°C to +70°C (-13°F to +158°F)

- Fluid Requirements: Mineral oil (ISO VG 32–68), NAS 1638 Class 6 (max), 80°C max fluid temp

- Mounting Torque: 15 Nm (11.1 ft-lbs) – flange bolts

- Weight: 2.1kg (4.6 lbs)

- Seal Type: Fluorocarbon or Buna options (per application)

- Certifications: CE, RoHS compliant; ATEX/IECEx (optional for hazardous areas)

- Compatible Systems: MOOG D136 MSC I Controllers, M3000 Motion Control Systems, small actuators (10–35mm bore), QAIO-001 analog expansion modules

Moog D633-481B

Field Application & Problem Solved

In low-pressure small hydraulic systems, the core challenge is balancing precision with adaptability. Pilot-operated valves are overly complex—they require extra pilot supply hardware that wastes space (critical in die casting machines or lab rigs) and increases maintenance. Generic proportional valves lack multi-signal compatibility and struggle with consistent positioning (±0.1mm tolerance) for tasks like die casting ejector alignment or paper edge guiding. A Zhejiang die casting plant was replacing pilot filters every 2 months, costing $9k annually and causing 1.5-hour downtime events. A Shandong paper mill faced 5% web scrap rates due to generic valves’ poor edge control accuracy.

This valve solves these issues with its compact Size 03 design and versatile performance. You’ll find it in: die casting ejectors (0.1mm positioning to prevent part sticking), paper machine edge guides (maintaining ±1mm web alignment at 400m/min), compact 5-20 ton presses (ram speed control at 200mm/s), lab test rigs (stable pressure/flow profiles for component testing), and petrochemical pipeline regulators (consistent hydraulic control for medium-pressure lines). Its core value is versatile precision—no pilot system cuts maintenance by 100%, multi-signal input fits existing control systems, and 350 bar pressure adapts to low-to-mid pressure scenarios. For the Zhejiang plant, it eliminated pilot filter costs and reduced downtime by 6 hours/year. For the Shandong mill, it dropped scrap rates to 0.8%.

Installation & Maintenance Pitfalls (Expert Tips)

- Fluid Cleanliness: NAS 1638 Class 6 Is Mandatory: The valve’s spool clearances are 0.005mm—NAS 8 oil will cause binding within 3–5 months. A Jiangsu lab replaced two valves after using 25µm filters; each failure delayed testing by 3 days. Fix: Install 10µm absolute filters (β10 ≥ 75 per ISO 16889) and test oil cleanliness every 1800 operating hours.

- Power Supply: Avoid Under-Voltage Below 19V DC: Running below the 19V minimum degrades PWM drive performance and increases response lag. A Guangdong press shop had erratic ram speed until we upgraded their 18V power supply to 24V. Fix: Use a 24V DC power supply with 3A capacity and add a 500µF capacitor to filter voltage droop.

- Mounting Torque: Stick to 15 Nm: Over-torquing (≥18 Nm) warps the thin Size 03 flange, causing spool binding. An Anhui test rig had flow fluctuations until we retorqued bolts to 15 Nm with a torque wrench. Use the cross-tightening sequence (1-3-2-4) for even force distribution.

- Signal Selection: Match Input to Controller: Using 4-20mA without proper scaling causes positioning errors. A Fujian petrochemical plant’s pipeline regulator drifted until we calibrated the valve to match their 4-20mA controller output. Fix: Refer to the manual to set the input signal type (±10V/±10mA/4-20mA) via the integrated DIP switches.

- Null Adjustment: Depressurize First: Adjusting null under pressure leads to drift in edge control or ejector alignment. A Henan paper mill’s web misalignment persisted until we bled the system and recalibrated null to 0V feedback (±0.01V). Lock the jam nut after adjustment—factory null drifts during shipping.

Moog D633-481B

Technical Deep Dive & Overview

The D633-317B is engineered for small-scale, low-to-mid pressure hydraulic systems where versatility and precision are non-negotiable. At its core, a permanent magnet linear force motor drives the spool directly, eliminating the pilot stage that plagues traditional valves. This design delivers two key benefits: simplified system integration (no pilot supply hardware) and consistent performance—direct drive ensures dynamic response independent of system pressure.

The integrated 24V PWM amplifier is a standout feature: it supports three common control signals (±10V/±10mA/4-20mA), fitting seamlessly into existing industrial control systems without extra converters. The closed-loop control uses an internal LVDT to track spool position within ±0.01mm, even as fluid temperature fluctuates. The LVDT’s non-contact design ensures no wear over time, while the hard-chromed spool (0.8µm surface finish) resists abrasion, extending service life to 20,000+ hours.

The spring-centered spool is safety-critical: power loss triggers neutral positioning, blocking flow to actuators and preventing unintended movement—essential for ejectors or press rams where component damage risks are high. The ISO 4401 Size 03 flange fits standard small hydraulic manifolds, enabling retrofits in under 1 hour with no manifold modifications.

Ruggedness matches its versatility: IP65 protection shields against dust and water jets (common in plant and lab environments), while fluorocarbon/buna seal options adapt to different mineral oil formulations. Unlike generic valves, it doesn’t sacrifice precision for compactness—75 L/min max flow moves small actuators efficiently, and PWM drive technology ensures smooth, accurate control. For maintenance teams, it’s low-effort: no pilot system to service, diagnostics via position feedback, and predictable lifespan with proper fluid care. It’s the reliable backbone of precision control in small-scale industrial and lab hydraulic systems.