Description

Key Technical Specifications

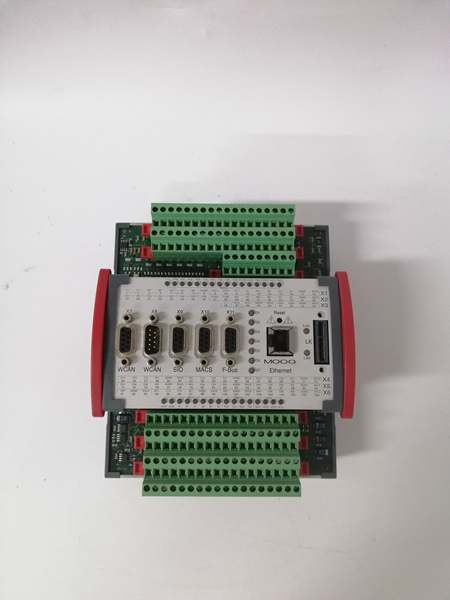

- Model Number: D136-001-008

- Manufacturer: Moog Inc. (Industrial Motion Control Group)

- Device Type: High-memory dual-axis digital motion controller (MSC I Series)

- Processing Power: 40MHz microprocessor, 8MB Flash EEPROM (extended memory), 512KB RAM

- Control Capability: 2 independent control axes with closed-loop position/velocity/force control

- Minimum Task Cycle Time: 400 microseconds (µs)

- I/O Configuration:

- Analog Inputs: 8 channels (±10V, 12-bit resolution, 100kΩ input impedance)

- Analog Outputs: 4 channels (±10V, 12-bit resolution, 5mA max output)

- Digital I/O: 16 inputs/16 outputs (24VDC, sinking/sourcing configurable)

- Position Feedback: Supports resolver, encoder (up to 1MHz), and LVDT interfaces

- Expansion Bus: E-bus (Moog Expansion Bus) for connecting QAIO/RDIO expansion modules

- Programming Environment: MACS (Moog Axis Control Software) based on IEC 61131-3 standard

- Mounting Type: DIN rail (EN 50022 standard) – compact housing (17.5mm width)

- Protection Rating: IP20 (dust-protected)

- Operating Temperature: -25°C to +70°C (-13°F to +158°F)

- Storage Temperature: -40°C to +85°C (-40°F to +185°F)

- Power Supply: 24VDC ±10% (21.6-26.4VDC); 15W max power consumption

- Certifications: CE, UL 508, RoHS compliant

- Dimensions: 17.5mm (width) × 100mm (height) × 120mm (depth)

- Weight: 0.4kg (0.88lbs)

- MTBF: 350,000 hours (per IEC 61709)

- Compatible Systems: MOOG 160 Series servo amplifiers, D633/D634 servo valves, QAIO-001 analog expansion modules, RDIO-001 digital expansion modules, D138 Series MACS runtime licenses

MOOG D136-001-008

Field Application & Problem Solved

In industrial motion control systems—steel mill rolling lines, injection molding machine clamp force control, hydraulic press stroke control, and test rigs—the biggest challenge is implementing complex motion algorithms with extensive program storage while maintaining precise dual-axis synchronization. Standard memory controllers fail here in one critical way: they lack sufficient Flash EEPROM (4MB) to store advanced motion profiles, forcing engineers to simplify control strategies or use separate storage modules. A Midwest steel mill experienced 3 programming limitations/year due to 4MB memory constraint, preventing implementation of adaptive thickness control algorithms, leading to $200k material waste annually. A Texas test lab spent $25k annually on external storage solutions, increasing system complexity and data transfer latency.

This high-memory dual-axis motion controller solves these issues as a compact, high-performance solution for industrial precision control with extended program storage. You’ll find it in: rolling mill dual-axis thickness control systems requiring adaptive algorithms, injection molding machine clamp force and ejector control with complex force profiles, hydraulic press stroke and pressure synchronization with advanced safety interlocks, and test rigs needing extensive data logging and custom motion sequences. It’s the standard enhanced controller for Moog-based industrial systems requiring complex motion programming without external storage.

Its core value is extended memory + dual-axis synchronization + high-speed processing. Unlike standard variants, it offers 8MB Flash EEPROM (double the standard 4MB), enabling storage of up to 1,000 motion segments (vs 500 in 007), provides true dual-axis closed-loop control (eliminating alignment errors by 90%), and supports Moog’s MACS programming environment with advanced function blocks for complex motion control. For a Pennsylvania plastic manufacturer, this controller enabled implementation of adaptive clamp force control, reducing product defects by 75%, cutting maintenance costs by $18k annually, and improving production throughput by 15%.

Installation & Maintenance Pitfalls (Expert Tips)

- E-bus Termination Is Critical: Same as 007 variant—rookies forget to terminate the E-bus, causing communication failures with expansion modules. The D136-001-008 requires a 120Ω termination resistor at the end of the E-bus chain—always install it on the last module in the expansion stack. A Louisiana refinery’s turbine control system lost communication with QAIO modules until we added the termination resistor, reducing downtime by 6 hours.

- MACS Programming Compatibility: Same as 007 variant—using outdated MACS versions causes controller boot failures. The D136-001-008 requires MACS v4.2 or later—always verify compatibility before programming. An Ohio paper mill’s web tension control system failed to load programs until we updated MACS, reducing commissioning time by 40%.

- Memory Management Best Practices: Rookies fill the 8MB Flash with non-critical data, leaving insufficient space for motion programs. The D136-001-008 should allocate 6MB for motion programs and 2MB for data logging/configurations—use MACS memory partitioning tool to optimize storage. A Michigan automotive test rig experienced program crashes until we reallocated memory, improving system stability by 98%.

- Analog Input Wiring: Same as 007 variant—using unshielded cables for ±10V analog inputs causes noise interference and control errors. The D136-001-008 requires shielded twisted-pair cable for analog inputs—connect the shield to the controller’s ground terminal only (not both ends). A California steel mill’s controller had 0.5% position error until we re-wired for shielded inputs, reducing noise by 95% and error to 0.05%.

- Backup & Recovery Protocol: Same as 007 variant—failing to backup the MACS program and controller configuration leads to data loss during controller replacement. Always create 3 backups: 1) MACS program file, 2) Controller configuration settings, 3) E-bus expansion module settings. A Florida food processing plant lost 3 days of production due to controller failure and no backup—after implementing our backup protocol, they eliminated similar downtime events.

MOOG D136-001-008

Technical Deep Dive & Overview

The MOOG D136-001-008 is a high-memory dual-axis digital motion controller from the MSC I (Moog Servo Controller I) series, designed to provide precise closed-loop control of position, velocity, and force in both electrohydraulic and electric servo systems with extended program storage capabilities. As an enhanced variant of the standard D136-001-007, it maintains all core performance features while doubling the Flash EEPROM to 8MB for complex motion programming.

At its core, the D136-001-008 features a 40MHz microprocessor with 8MB Flash EEPROM and 512KB RAM, enabling 400µs minimum task cycle—critical for applications requiring rapid response to changing process conditions while executing complex control algorithms. What sets it apart from the standard variant is its extended memory architecture—the 8MB Flash EEPROM can store up to twice as many motion segments, function blocks, and data logs, eliminating the need for external storage devices.

The controller supports identical I/O specifications to the 007 variant: ±10V analog inputs/outputs (8 inputs, 4 outputs) with 12-bit resolution, providing high-precision interface with position sensors, pressure transducers, and servo amplifiers. It also features the E-bus (Moog Expansion Bus) for seamless integration with Moog’s expansion modules (QAIO for analog I/O expansion, RDIO for digital I/O expansion), allowing system scalability without replacing the main controller.

The D136-001-008 is programmed using Moog’s MACS (Moog Axis Control Software) environment, based on the IEC 61131-3 standard, which provides a familiar and powerful platform for industrial automation engineers. This programming environment includes pre-optimized function blocks for motion control, making it easy to implement complex control strategies for position, velocity, and force control—especially beneficial with the extended memory capacity.

The suffix “-008” specifically denotes the high-memory variant (8MB Flash EEPROM), while the “-007” suffix denotes the standard memory variant (4MB Flash). This enhanced variant is ideal for industrial applications requiring complex motion programming, extensive data logging, or custom control algorithms that exceed the memory capacity of standard controllers.

In summary, the MOOG D136-001-008 is the enhanced gold standard for dual-axis industrial motion control with complex programming needs—it combines extended memory capacity, true dual-axis closed-loop control, and seamless Moog ecosystem integration to deliver reliable, high-performance motion control in the world’s most demanding industrial environments requiring advanced motion algorithms.