Description

Detailed parameter table

| Parameter name | Parameter value |

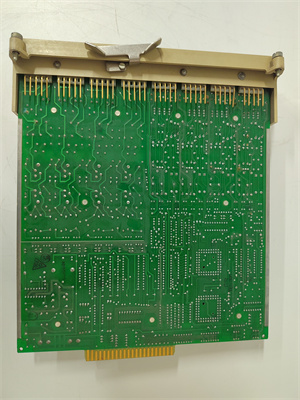

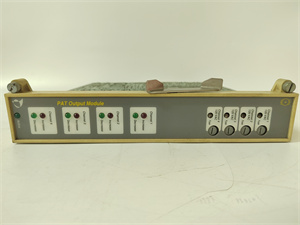

| Product model | Metso IOP111 |

| Manufacturer | Metso Outotec Corporation |

| Product category | PAT Output Module |

| Output Signals | Supports PAT (Process Automation Technology) output signals, suitable for driving various actuators in industrial processes. |

| Number of Output Channels | Configuration varies; typically available in 4, 8, or 16-channel versions to meet different application needs. |

| Output Voltage | 24 VDC standard output, with a tolerance range of ±10% to ensure stable operation in industrial power supply environments. |

| Output Current | Each channel can drive a maximum load current of 0.5 A, sufficient for most small to medium-sized actuators. |

| Response Time | Fast response time of less than 10 ms, enabling quick control actions in real-time industrial processes. |

| Communication Interface | Equipped with Modbus RTU (RS-485) interface, standard baud rate of 9600, with options for other baud rates (19200, 38400) configurable through software. |

| Physical Dimensions | Compact design with dimensions of 100 mm (width) × 120 mm (height) × 70 mm (depth) for the 4-channel version. Dimensions scale proportionally for higher channel counts. |

| Weight | Approximately 500 g for the 4-channel version, increasing with additional channels. |

| IP Rating | IP20 rated, suitable for indoor use in control panels, providing basic protection against dust. |

| Environmental Requirements | Operating temperature range: -10 °C to +55 °C, allowing operation in a wide range of industrial environments. Storage temperature: -20 °C to +65 °C. Relative humidity: 10% – 90% non-condensing. |

| Power Requirements | Operates on 24 VDC power supply, with a power consumption of less than 2 W for the 4-channel version, increasing slightly with more channels. |

| Safety & Compliance | Complies with CE (EN 61010-1) safety standards, ensuring safe operation in industrial settings. RoHS 2 compliant for environmental friendliness. |

| Compatibility | Compatible with major PLC systems such as Siemens S7-300/400, Allen-Bradley ControlLogix, and Schneider Modicon M340. Supports standard industrial communication protocols for seamless integration. |

| Additional Features | LED indicators for each channel to show output status (green for active output, red for fault). Built-in overcurrent protection for each channel to safeguard against short circuits. |

METSO IOP111

Product introduction

The Metso IOP111 is a high – performance PAT Output Module designed by Metso Outotec. It plays a crucial role in industrial automation systems, acting as a bridge between the control system and the actuators. By converting digital control signals from the PLC into PAT output signals, it enables precise control of various industrial processes. For example, in a chemical plant, the IOP111 can be used to control the opening and closing of valves, regulating the flow of chemical substances accurately.

Compared to some of its competitors, the IOP111 stands out with its flexible channel configuration. Users can choose from 4, 8, or 16 – channel versions based on the complexity of their process control requirements. This adaptability makes it suitable for applications ranging from small – scale manufacturing units to large – scale industrial plants.

Core advantages and technical highlights

Flexible Channel Configuration

The ability to select from 4, 8, or 16 – channel versions allows for cost – effective system design. In a small food processing plant, a 4 – channel IOP111 can be used to control the filling process of four different product lines. As the plant expands and more processes need to be automated, upgrading to an 8 – or 16 – channel module is a seamless process, without the need to replace the entire control infrastructure.

Fast Response Time

With a response time of less than 10 ms, the IOP111 is ideal for applications where real – time control is critical. In a high – speed packaging line, the module can quickly respond to changes in product detection sensors, ensuring that the packaging machinery operates in sync with the product flow. This fast response helps to minimize product waste and increase overall production efficiency.

Wide Compatibility

The IOP111’s compatibility with major PLC systems and standard industrial communication protocols simplifies system integration. In a multi – vendor industrial automation project, the module can easily communicate with different brands of PLCs. For instance, in a power generation plant where Siemens S7 – 300 PLCs are used for overall plant control and Allen – Bradley drives are used for motor control, the IOP111 can integrate smoothly, enabling coordinated operation of all components.

Built – in Overcurrent Protection

Each channel of the IOP111 is equipped with overcurrent protection. In a manufacturing facility where electrical malfunctions are common, if an actuator connected to the IOP111 experiences a short circuit, the overcurrent protection will immediately cut off the power to that channel. This protects the module from damage and prevents potential downtime, saving on maintenance and replacement costs.

Typical application scenarios

Manufacturing Industry

In an automotive manufacturing plant, the IOP111 can be used to control the movement of robotic arms. The 16 – channel version can manage multiple robotic arms simultaneously, ensuring precise and coordinated movement during the assembly process. Each channel controls a different actuator on the robotic arm, such as joints and grippers. The fast response time of the IOP111 enables the robotic arms to move quickly and accurately, increasing production speed and reducing errors.

Process Industry

In a pharmaceutical production facility, the IOP111 is used to control the dosing of various chemicals during the drug manufacturing process. The 8 – channel version can control eight different dosing pumps, each delivering a specific chemical in precise quantities. The module’s stable output voltage and current ensure accurate dosing, which is crucial for maintaining the quality and consistency of pharmaceutical products.

Energy Sector

In a wind farm, the IOP111 is employed to control the pitch and yaw of wind turbines. The 4 – channel version can be used to control two pitch actuators and two yaw motors on each turbine. By adjusting the pitch and yaw, the wind turbines can capture wind energy more efficiently. The wide temperature operating range of the IOP111 (-10 °C to +55 °C) makes it suitable for the harsh outdoor conditions of wind farms.

METSO IOP111

Related model recommendations

Metso IOP112: An upgraded version of the IOP111 with additional features such as advanced diagnostic capabilities. It can provide more detailed information about the status of the output channels, helping maintenance personnel to quickly identify and resolve issues.

Metso PS – 241: A 24 VDC power supply specifically designed to power the IOP111. It offers high – efficiency power conversion and stable output, ensuring reliable operation of the module.

Siemens S7 – 1500 PLC: A high – performance PLC that pairs well with the IOP111. It provides powerful processing capabilities and extensive communication options, enabling complex automation scenarios when used in combination with the IOP111.

Allen – Bradley CompactLogix PLC: A compact and cost – effective PLC that is fully compatible with the IOP111. It is suitable for small to medium – sized industrial applications where space and cost are important considerations.

Schneider Electric Modicon M580 PLC: A modular PLC with advanced features. When integrated with the IOP111, it can provide a comprehensive control solution for large – scale industrial processes.

Metso TC – 100: A terminal block kit for the IOP111. It simplifies the wiring process and provides a secure connection for the module’s input and output signals.

Metso IOP221: A digital input module that can be used in conjunction with the IOP111. It allows for the integration of digital sensors, expanding the functionality of the overall control system.

Industrial Ethernet Switch: To enhance the communication capabilities of the IOP111 in a networked environment. It enables high – speed data transfer between the module, PLCs, and other devices in the industrial automation system.

Installation, commissioning and maintenance instructions

Installation preparation

Before installation, ensure that the power to the entire control system is switched off. Wear an ESD (Electro – Static Discharge) wristband to protect the sensitive electronic components of the IOP111. Mount the module on a standard 35 mm DIN rail. For the 4 – channel version, ensure that there is at least 10 mm of clearance on both sides for proper ventilation. When wiring, use stranded wires with a cross – sectional area of 0.5 – 1.5 mm². Strip the wires to a length of 8 – 10 mm and insert them into the terminal blocks of the IOP111. Tighten the terminal screws to a torque of 0.5 – 0.6 N·m. Connect the power supply wires (24 VDC + and -) to the designated terminals on the module. For the communication interface, use a shielded twisted – pair cable for the Modbus RTU connection. Connect the A and B wires of the cable to the corresponding terminals on the IOP111 and the PLC.

Commissioning and maintenance

After installation, power on the control system. Check the power LED on the IOP111, which should turn green, indicating that the module is receiving power. Use a multimeter to verify the output voltage of each channel. Set the output to a known value in the PLC program and measure the voltage at the terminal block of the corresponding channel on the IOP111. It should be within the specified tolerance range. Check the LED indicators for each channel. If an output is active, the corresponding LED should be green. If there is a fault, such as an overcurrent, the LED will turn red.

For maintenance, perform a visual inspection of the module every 6 months. Check for any signs of physical damage, such as cracks or burn marks. Inspect the terminal connections for any signs of looseness. If a channel shows a red LED, first check the connected actuator for any malfunctions. Disconnect the actuator and use a short – circuit tester to check if the overcurrent protection is functioning properly. If the problem persists, consider replacing the module. Store spare IOP111 modules in a dry, cool environment with a temperature between 0 °C and 30 °C.

Service and guarantee commitment

Metso provides a 1 – year standard warranty for the IOP111. The warranty covers defects in materials, workmanship, and performance. If the module fails within the warranty period under normal operating conditions, Metso will replace it free of charge. To claim the warranty, customers need to provide proof of purchase.

Metso offers technical support for the IOP111 through a dedicated online support portal. Customers can access user manuals, technical documentation, and troubleshooting guides. In case of more complex issues, they can also contact Metso’s technical support team via email or phone. The response time for technical support requests is within 24 hours.

For out – of – warranty issues, Metso offers a repair service. The repair cost is based on the type of problem and the components that need to be replaced. Metso also provides a 3 – month warranty on repaired modules. Additionally, customers can purchase a service contract for extended support, which includes regular system health checks and priority technical support.