Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | 893-515602-002 |

| Manufacturer | LAM Research |

| Product category | Vacuum Pump Control Module (for Semiconductor Processing Vacuum Systems) |

| Controlled Pump Types | Dry scroll pumps, turbomolecular pumps, roots pumps (single/multi-stage) |

| Pump Power Regulation | 200–480V AC (3-phase), 50/60 Hz; 15A max continuous current; 30A peak current (startup) |

| Vacuum Monitoring Range | 10⁻⁹ Torr to 1 atm (compatible with ionization gauges, Pirani gauges, capacitance manometers) |

| Interface Type | Ethernet (10/100/1000Base-T); RS-485; 2x 40-pin terminal blocks (power/pump signals); 1x USB-C (configuration); 3x sensor input ports (BNC for gauge signals) |

| Communication Protocol | Modbus TCP/IP, EtherNet/IP, LAM Proprietary VacuumLink™ v3.1 |

| Operating Temperature Range | 5°C to 50°C (non-condensing) |

| Relative Humidity Tolerance | 10% to 85% RH (non-condensing, no moisture ingress) |

| Physical Dimensions (W×H×D) | 260mm × 320mm × 150mm (excluding connectors/terminal blocks) |

| Installation Method | 19-inch rack mounting (4U height); panel mounting (with vibration-dampening brackets) |

| Certifications | CE, UL 61010-1, SEMI S2/S8/S14 (semiconductor safety/EMC/vacuum standards) |

| Power Consumption | 24V DC (logic): 1.2A typical; 480V AC (pump power): variable (depends on pump load) |

| Monitoring Metrics | Pump speed (RPM), motor temperature, inlet pressure, oil level (for oil-sealed pumps), power consumption |

| Safety Features | Over-current protection, over-temperature shutdown (pump motor >120°C), low-oil alert, emergency stop (E-stop) input, vacuum leak detection |

| Control Modes | Auto-start/stop (via pressure setpoint), manual control, remote trigger (from chamber controller) |

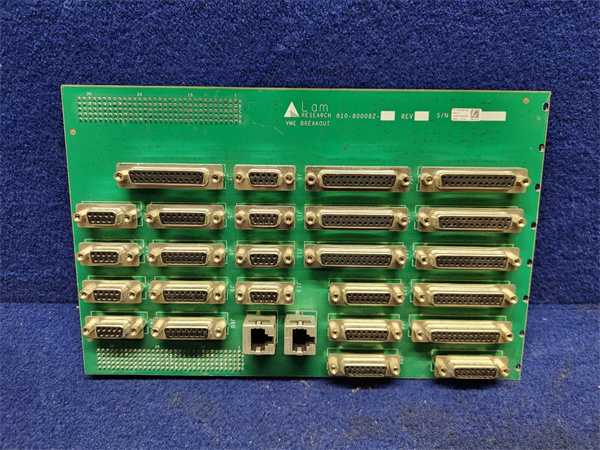

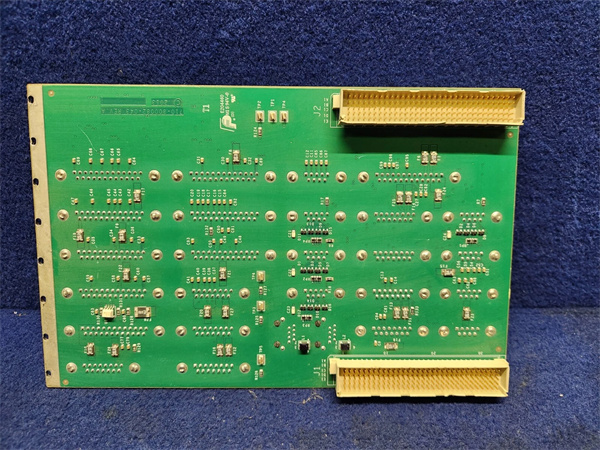

LAM 810-800082-043

Product Introduction

The 893-515602-002 is a high-performance vacuum pump control module developed by LAM Research, engineered to serve as the “command and protection center” for vacuum pumps in semiconductor processing tools—including Centura® Etch, Sym3® CVD, and Versys® Metal Deposition systems. Unlike generic pump controllers that only handle basic on/off functions, this module integrates precise power regulation, real-time vacuum monitoring, and proactive fault protection—critical for maintaining the ultra-clean, stable vacuum environments required for advanced 5nm–3nm process nodes.

As a flagship model in LAM’s Vacuum System Series, the 893-515602-002 addresses a key challenge in semiconductor manufacturing: ensuring vacuum pumps operate efficiently while avoiding damage from overheating, overloading, or vacuum leaks. Its core function is to regulate pump power (200–480V AC, 3-phase) to maintain target vacuum levels (10⁻⁹ Torr to 1 atm), monitor pump health metrics (e.g., motor temperature, RPM), and trigger protective actions (e.g., shutdown) if anomalies occur. In automation systems, it acts as a critical link between the 839-101870-002 pressure control module and vacuum pumps—synchronizing pump operation with chamber pressure demands to minimize energy waste and maximize pump lifespan.

Core Advantages and Technical Highlights

Multi-Pump Compatibility and Precise Power Regulation: The 893-515602-002 supports all major vacuum pump types used in semiconductors—dry scroll pumps (for roughing), turbomolecular pumps (for high vacuum), and roots pumps (for booster stages)—eliminating the need for dedicated controllers per pump. Its 3-phase power regulation (200–480V AC) delivers precise current control (±0.5A), ensuring pumps ramp up smoothly (avoiding startup surges that damage motor windings) and maintain consistent speed even under variable load (e.g., chamber pressure fluctuations). For example, when paired with a turbomolecular pump in a 3nm etch chamber, the module adjusts power to maintain 90,000 RPM—critical for achieving 10⁻⁸ Torr vacuum levels—while preventing over-speeding (a common cause of pump failure).

Real-Time Vacuum Monitoring and Leak Detection: Equipped with three sensor input ports (compatible with ionization gauges, Pirani gauges, and capacitance manometers), the 893-515602-002 provides granular vacuum data (10⁻⁹ Torr to 1 atm) with a sampling rate of 10Hz—far faster than legacy controllers (1Hz). This allows it to detect subtle pressure rises (indicative of vacuum leaks) within 1 second, triggering alerts to the main chamber controller (e.g., 810-102361-222) and adjusting pump power to compensate. For 5nm CVD processes, this leak detection prevents ambient air ingress (which causes film contamination) and reduces wafer scrappage by up to 35% compared to controllers lacking real-time monitoring.

Proactive Pump Protection and Longevity: Unlike basic controllers that only react to faults, the 893-515602-002 includes proactive safety features to extend pump lifespan. Its over-temperature shutdown activates when pump motor temperature exceeds 120°C (preventing winding damage), while low-oil alerts (for oil-sealed pumps) ensure lubrication is maintained before wear occurs. It also logs pump health data (e.g., RPM trends, power consumption) for up to 90 days, enabling maintenance teams to predict failures (e.g., a gradual RPM drop indicating bearing wear) and schedule proactive replacement—reducing unplanned downtime by 40% compared to reactive maintenance.

Seamless Integration with Chamber Automation: The 893-515602-002 uses LAM’s VacuumLink™ v3.1 protocol to synchronize with other subsystems. When the 839-101870-002 pressure module detects the chamber needs roughing (from 1 atm to 1 Torr), it sends a signal to the 893-515602-002, which auto-starts the dry scroll pump and ramps up power to meet demand. Once roughing is complete, the module switches to the turbomolecular pump for high-vacuum operation—all without manual intervention. This automation reduces process cycle time by 15% (vs. manual pump switching) and ensures consistent vacuum transitions across every wafer.

Typical Application Scenarios

The 893-515602-002 is indispensable in fabs for vacuum-critical processes, with two high-impact use cases: high-vacuum plasma etching for 3nm logic devices and ultra-high-vacuum (UHV) deposition for 5nm memory chips.

In 3nm logic plasma etching (e.g., LAM’s Centura® AdvantEdge™ Etch), the 893-515602-002 controls a turbomolecular pump (for high vacuum) and a dry scroll pump (for roughing). It receives pressure setpoints from the 839-101870-002 (e.g., 10⁻⁷ Torr for etching) and adjusts pump power to maintain this level—even as the chamber is periodically vented for wafer transfer. Its leak detection feature identifies small leaks (e.g., from a worn chamber O-ring) by detecting pressure rises >0.1 Torr/min, triggering an alert before the leak degrades etch uniformity. Fabs using this setup report a 28% reduction in pump-related downtime, as the module prevents catastrophic pump failures and enables scheduled maintenance.

In 5nm memory UHV deposition (e.g., Sym3® Metal Deposition for 3D NAND), the 893-515602-002 controls a turbomolecular pump paired with an ionization gauge to maintain 10⁻⁹ Torr vacuum—critical for preventing metal film contamination. The module synchronizes pump operation with the 810-017006-001 gas mixing module: when precursor gases are introduced (e.g., TiCl₄ for metal deposition), the 893-515602-002 increases pump power to maintain vacuum, ensuring excess precursor is removed quickly. Its motor temperature monitoring also prevents overheating during long deposition runs (e.g., 8-hour batches), extending pump lifespan by 50% compared to using unmonitored pumps.

LAM 810-800082-043

Related Model Recommendations

LAM 893-515602-003: An upgraded variant of the 893-515602-002 with dual pump control (supports 2 pumps simultaneously) and extended vacuum range (10⁻¹¹ Torr to 1 atm), designed for UHV processes like molecular beam epitaxy (MBE).

LAM 893-515602-001: A compact variant of the 893-515602-002 (3U rack height, 1-phase power 110–240V AC) for small-scale tools (e.g., R&D etch chambers) using single dry scroll pumps.

LAM 893-515603-002: A redundant vacuum pump controller that pairs with the 893-515602-002 for fault-tolerant fabs (e.g., high-yield memory production), automatically taking over if the primary module fails to prevent vacuum loss.

LAM 893-515601-002: A legacy replacement for LAM’s pre-2019 vacuum pump controllers (e.g., 893-515600-001), fully compatible with the 893-515602-002’s mounting, power, and protocol support.

LAM 893-515602-004: A high-temperature variant of the 893-515602-002 (operating range: -10°C to 60°C) with enhanced cooling, designed for use near high-heat tools (e.g., MOCVD systems for compound semiconductors).

LAM 893-515604-002: A vacuum gauge calibration accessory module that provides NIST-traceable pressure references (10⁻⁹ Torr to 1 atm) for the 893-515602-002, simplifying on-site gauge calibration.

LAM 893-515602-005: A wireless-enabled variant of the 893-515602-002 (Wi-Fi 6, Bluetooth 5.2), enabling remote monitoring of pump health and vacuum levels for hard-to-access pump rooms.

LAM 893-515605-002: A energy-saving accessory module that optimizes the 893-515602-002’s power regulation, reducing pump energy consumption by up to 20% during low-load periods (e.g., chamber idle time).

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Before installing the 893-515602-002, ensure the 19-inch rack is rated for 4U height and 60kg load (including wiring), and the ambient temperature is 5–50°C. Required tools include a torque wrench (3.5 N·m for rack mounting), multimeter (to verify 200–480V AC 3-phase power), ESD-safe gloves/wristbands, vacuum gauge (for calibration), and a laptop (for USB-C configuration). Safety precautions: Disconnect facility power (lockout/tagout) before wiring; use shielded cables for gauge signals to minimize EMI (critical for accurate vacuum readings); confirm the module’s ground connection (≥6AWG wire) is secure to prevent electrical hazards; and label pump power cables clearly to avoid phase miswiring (which damages pumps). Avoid mounting near vibration sources (e.g., pump motors) to prevent loose connections.

Maintenance Suggestions: For daily maintenance, check the 893-515602-002’s front-panel LED indicators (green = normal, amber = warning, red = fault) and review pump metrics (temperature, RPM, pressure) via VacuumLink™ software. Every 3 months, inspect terminal blocks for loose wiring (retorque to 1.0 N·m) and clean the module’s air vents with compressed air (≤50psi) to prevent overheating. Every 6 months, calibrate vacuum gauges using the LAM 893-515604-002 accessory to maintain pressure reading accuracy (±0.5% of full scale). For oil-sealed pumps, check oil levels monthly and replace oil per LAM’s guidelines (typically every 6 months). If a fault occurs (e.g., over-temperature), first shut down the pump, isolate the module from power, and use the diagnostic log to identify the cause (e.g., clogged pump air filter, faulty temperature sensor)—never bypass safety features (e.g., E-stop) to resume operation.

Service and Guarantee Commitment

The 893-515602-002 comes with a 48-month manufacturer’s warranty from LAM Research, covering defects in materials, workmanship, and vacuum control performance under normal use (per SEMI S2/S8 standards). If the module fails within the warranty period, LAM provides a “rapid swap” service—delivering a pre-configured replacement unit within 24 hours (for Priority Service customers) to minimize vacuum system downtime, with no cost for repair, shipping, or reconfiguration.

LAM offers 24/7 technical support for the 893-515602-002, including access to vacuum system specialists via phone/email, remote diagnostics (via secure Ethernet), and on-site troubleshooting (available within 48 hours globally). The module includes free access to LAM’s VacuumSuite™ software (for configuration, monitoring, and firmware updates) for 5 years post-purchase, ensuring compatibility with new pump technologies (e.g., next-gen dry turbopumps for 2nm nodes).

To enhance reliability, LAM offers a Vacuum Pump Care Program for the 893-515602-002, which includes scheduled on-site pump health checks, proactive gauge calibration, and firmware updates—tailored to the fab’s pump maintenance schedule (e.g., monthly roughing pump inspections). This commitment reflects LAM’s confidence in the 893-515602-002’s quality and its dedication to supporting customers’ vacuum-critical semiconductor manufacturing operations.